It's time to do electrics in the garage. And although the garage at the bottom is cluttered, I decided to drive the light (I somehow drove the car into the garage late at night and almost got into the stairs to the second floor). And the neighbor began to creek, so I removed the temporary pillar,

which was associated with his fence.

I called professional electricians who immediately climbed onto the main pillar (where the meters stood) and said that they would have to work under voltage, since there is simply no power switch, so it will cost more. I agreed (nowhere to go!). And they set about.

I had all the tools and accessories: a puncher, a long drill Ø20 mm (for a plastic tube), an electric shield was purchased for 8 positions of single automatic machines, automatic machines from Legrand (I respect this company), electrical boxes 26x16 mm in the amount of 6 pcs., powerful hooks, where the cable tie is attached. On a temporary pillar hung a twisted SIP-16, which once went to the house. Its length should have been enough to the shield installed in the corner of the garage in front of the stairs.

Professionals demolished a temporary pillar, drilled a hole in the wall under the roof overhang, clogged a plastic pipe and brought it into the SIP garage that came from the meter. They screwed the hook, pulled the wire and foamed the hole.

Further, the electrical boxes went into work.

The boxes were laid under the ceiling above the stairs. On the second box passes SIP for powering the house. SIPs were connected to the input of the main machine. Then the procedure was repeated, as on the back wall.

Through the “nuts” the house was connected. On this, the work of the pros was completed.

I bought a 10-LED LED spotlight UINEL (just 290 rubles), because in the evenings it was dark to work with the shield.

It shines very brightly.

What we have:

25 A twin machine (main), 16 A machine (light in the garage), 16 A machine (future outlets in the garage), 16 A machine (sockets on the second floor) and 10 A machine (light on the second floor )

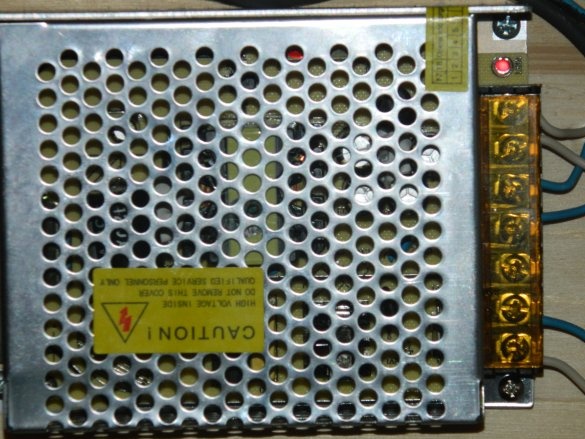

I started with the lights in the garage. For this, 6 m of LED strip LC-5050-W-12WW60 were purchased

(the Chinese claim that 15 W / m - they say lies, God forbid 12) and three radiator profiles with diffusers: two angular and one straight (2 m each). Moisture-proof tape, self-adhesive. A UINEL transformer for 12 V / 150 W tape was also purchased.

The transformer has 2 tape outputs so as not to overload it. Corner profiles were fixed on the walls of the garage, a straight line - on the ceiling of the garage at the rear. The tapes were connected 2 + 2 in series and 2 separately. Installation was carried out by a wire VVG NG 2x1.5 (single core), because on the ground floor there is still a chance of humidity.Tapes were connected to different outputs of the transformer. The transformer is switched on by a switch located under the shield.

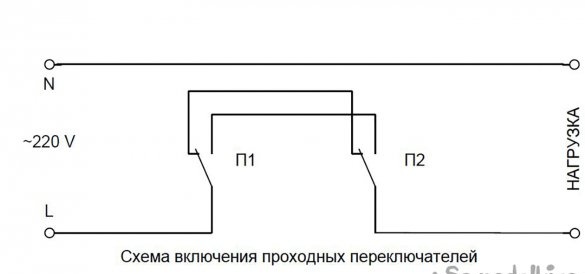

Then he took up the walk-through switches. The scheme of their connection is presented on the image. One is installed under the shield, the second is at the top of the stairs.

The wiring was conducted by the wire VVG NG 3x1.5. As a load, a homemade LED lamp was used.

[/ center]

[/ center]I also decided to put a socket under the shield.

All wires were removed into the cable channels “pine” 12x12 mm (in the amount of 16 pcs. Gave them a neighbor - a freebie!). Part was broken, but something could be used.

So what we have.

From left to right: LED strip switch, spotlight switch, pass switch.

I still had junction boxes, on one of which I once made a spider lamp, which is standing on my top landing. I bought the smallest DIN rail strips.

With a little refinement, they perfectly got into the boxes.

I also bought multicore cables PBVV 2x1.5 - 25 m (for lighting at the top) and PUVV 2x2.5 - 20 m (for outlets in the same place). I bought cable channels “pine” 15x10 mm - 8 pcs.

I connected the wires to the shield and began to pull them along the stairs.

First he pulled the cable under the sockets, led along the wall of the garage,

I drilled a hole in the wall with a Ø10 mm long drill and, on the other hand, set up a junction box.

I did the same operation with the cable under the light.

Thus, the junction boxes were on opposite sides of the door. For all these operations, I spent the remains of the 12x12 mm cable channel.

While I decided to put two chandeliers, one of them illuminates the place in front of the fireplace, the second (main) - a place above the table (as planned) in front of the window.

I started by installing a two-key switch (also Legrand) and cable channels 15X10 mm.

It was hard when I pulled two wires at once through the cable channels during transitions, and especially on the ceiling.

After hanging the first chandelier by the fireplace, it became easier.

I hung the second chandelier in about 15 minutes. All the chandeliers have purchased GAUSS LED lamps.

For now - a pause. I did not install sockets in the room, because my wife wants a small kitchenette (and there I need to install the sockets in place), and I want a small repair room (but for this I need to disassemble the garage). We will still have to think about how to bring water to the second floor (and this is a big problem, because you have to download water for about an hour, so that the water goes clean!) And drain. It is unclear how the bed will be located in order to put the outlet under the sconce, where the TV will hang (or stand).

And I dream to put a rocking chair in front of the fireplace and, while sipping beer, look at the fire ..

Materials used for electrics:

Legrand machines:

1. Twin 25 A - 1 pc.

2. Single 16 A - 3 pcs.

3. Single 10 A - 1 pc.

The panel hinged closed under automatic machines 8 position plastic IP66 - 1 pc.

LED strip LC-5050-W-12WW60 15 W / m IP65 - 6 m

Transformer for tape 12 V / 150 W UINEL - 1 pc.

Profile for tape with diffusers:

Corner 2 m - 2 pcs.

Direct 2 m - 1 pc.

Wires:

SIP-16 - for consumption

VVG NG 2x1.5 - 10 m

VVG NG 3x1.5 - 10 m

PBGVV 2x1.5 - 25 m

PUGVV 2x2.5 - 20 m

Electrical boxes:

26x16 mm “white” - 6 pcs.

12x12 mm “pine” - 16 pcs. (freebie! - gave the neighbor)

15x10 mm “pine” - 8 pcs.

LED spotlight 10 W UINEL - 1 pc.

Two Legrand loop switches

Three single Legrand circuit breakers

One two-gang switch Legrand

Double Legrand socket - 1 pc.

All this music cost about 11,000 rubles. + gave 8000 rubles. pros to switch from a temporary post to the garage and the house.