I welcome all fans to craft, I propose to consider instructions for the manufacture of a motorized jack do it yourself. As a basis, the usual mechanical car jack, which is driven by an automobile motor from the wipers. The vice works perfectly, the compression force is enough for reliable clamping of the product. To control such a vice was convenient, you can make a pedal with two positions. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- motor from car wipers;

- car jack frog;

- channel;

- thick sheet steel;

- screws and washers;

- paint for metal.

Tool List:

- Miter saw;

- grinder;

- welding machine;

- drill;

- files;

- taps for threading;

- vise;

- marker;

- roulette.

Manufacturing process homemade:

Step one. Foundation preparation

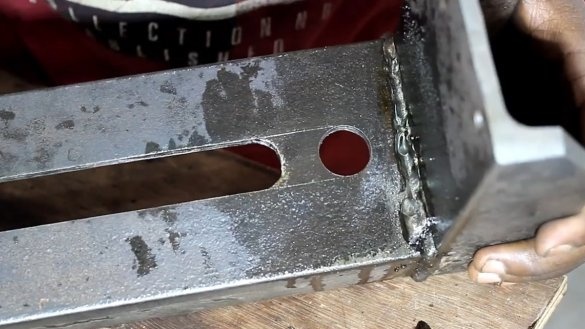

First of all, we will prepare the basis for the vice, here we need a piece of a strong channel. We cut the channel to the desired length and clean it from rust. Next, along the channel, you need to cut a slot hole, which will serve as a guide for the movable lip.

Having determined the beginning and end of the slot, the author drills a crown from both ends of the hole. Next, these holes must be combined with each other using a grinder. Of course, after cutting, we definitely modify the slot with files so that everything is smooth and nothing clings.

Step Two Fixed lip

The fixed lip is also cut out from a piece of the channel and welded to the base. Do not forget to drill holes in the lip and cut the thread for the screws that will hold the pad.

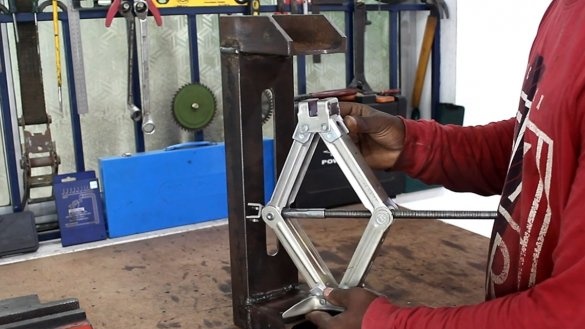

Step Three Moving lip

We cut a movable lip from the channel, we weld its base with a piece of a thick steel plate. Across this plate, we weld another one, its width should correspond to the width of the groove in the base, this will be the guide.

We drill holes in the guide and cut the threads for the screws. A steel plate will be placed on the back of the base, and this whole thing will be delayed. In order to obtain a certain gap between the plates, the author places washers of suitable thickness between them.

At the end, on the side of the lip, you need to weld another plate, drilling a hole in it and cutting the thread. This will be a support for one of the sides of the jack, the jack will be screwed on.

The reverse side of the jack abuts against the stop from the channel, welded to the base.

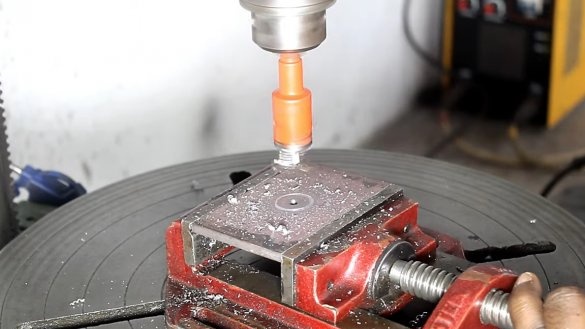

Step Four Lining

We make good linings for the lips of the vice, and for the most part it will depend on them how the vice will hold the product securely. Pads are usually made of durable hardened steel. We cut out two plates and drill holes for the screws. On the plates, it would be nice to make notches, so that there are cloves that will bite into the material.

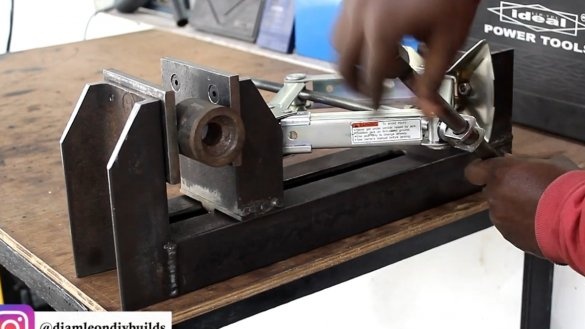

Step Five Motor

The manual version of the vise already works and copes well with the tasks, it remains to put the motor. The author made fasteners for the motor from a steel plate, as a result, this fastener is mounted on a jack.

To connect the shafts, the author put a piece of steel plate on the motor shaft, which goes into the “plug” on the axis of the jack.

Step Six Final touches and tests

Everything is ready, we finally weld everything, we clean the welds and paint the homemade product. The vice looks good, it’s important not to forget to weld the hinges with which the vice will be attached to the table.

You can connect a motor, we need a reverse switch, and it’s better to make a pedal so that your hands are free. You need to power the motor with a voltage of 12V, the author uses a battery. The vice works perfectly, the author reliably clamps pipes of different diameters and cuts.

The project is completed on this, I hope you liked the homemade work, and you found useful thoughts. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!