For the manufacture of most homemade bicycle trailers welding equipment needed. But not everyone has a welding machine and not everyone has the skills to work with it. The master offers his own manufacturing option. cycling trailer without welding. The master uses an aluminum profile to assemble the trailer. Often, guides for CNC machines are assembled from such profiles.

Tools and materials:

- Aluminum profile 20X20;

-Aluminum profile 20X40;

-Fittings for assembly;

-Fasteners;

-Furniture shock absorber;

- Allen key;

-Tool for cutting profile;

-Bicycle wheel;

-Bearings;

-Aluminum tube;

-Plastic orange;

-Scotch;

-Brackets;

-Plastic case;

The full catalog of parts that the wizard used in his project can be downloaded from the link below.catalogo.pdf.

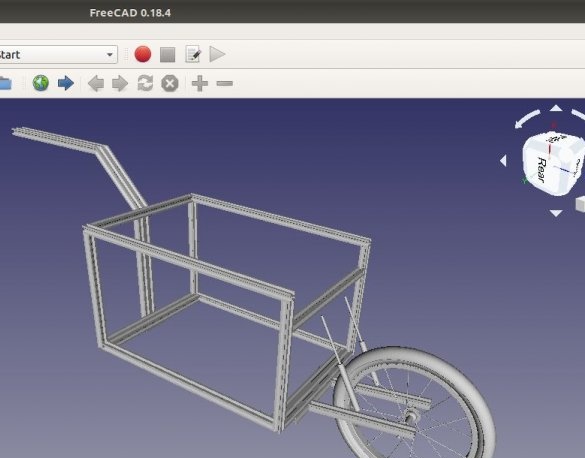

Step One: Design

First, the wizard designs the trailer in the FreeCAD program. You can download the file and make the changes you need according to this the link.

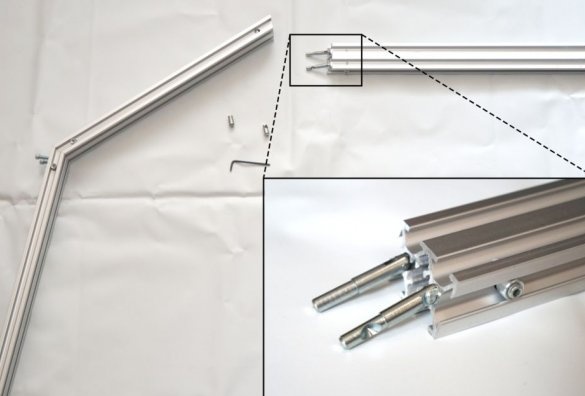

Step Two: Frame

The wizard does not give a detailed description of each step, only a general concept.

Profiles are cut to size, and the wizard begins assembly.

Fastening parts with hinges, brackets, corners.

Step Three: Wheel

To install a 16 "wheel, the master made an aluminum mount.

Step Four: Shock Absorbers

Unlike trailers with springs, the master decided to install two furniture shock absorbers on his trailer.

Step Five: Lever

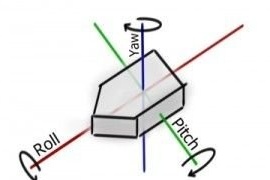

The lever is also made of aluminum profile. To fix the lever to the bicycle frame, the master made a bracket. A bearing is mounted at the attachment point, and this allows the trailer to turn left and right, and the axis, and this allows the lever to work like a pendulum up / down.

Step Six: Signal Flag

The master fixes a plastic case on the trailer

and signal flag. The trailer is low profile, and in order to avoid an emergency, a signal flag is a necessary thing.

All is ready.