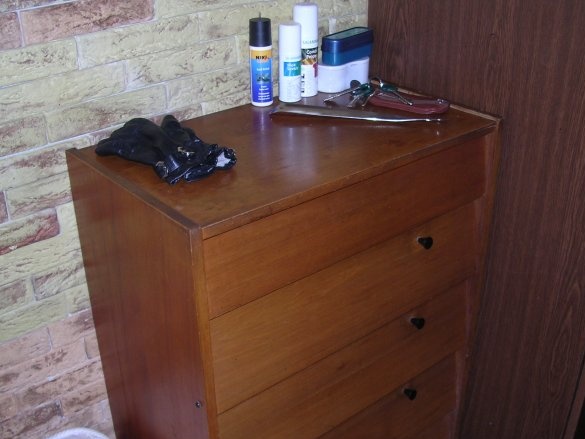

It was in those years when they did not hear about slim bedside tables for shoes. Then the thought came up how to arrange the shoes in the nightstand so that it fits more with the smaller sizes of the nightstand - obliquely. The idea of such a bedside table was brought to life, and it has been serving me faithfully for many years.

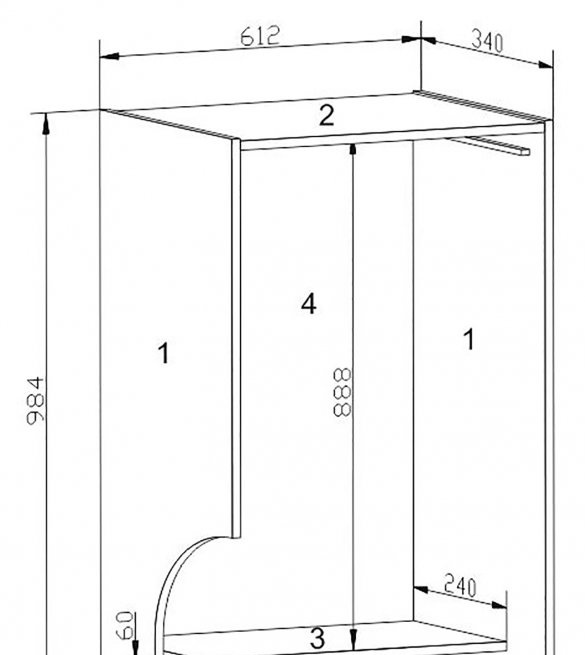

The design of the nightstand is very simple. The basis of the bedside table is the skeleton, which is assembled from the following parts: two side walls 1upper 2 and lower 3 panels and back wall 4which is a waybill.

Using the dowels on PVA glue from veneered chipboard with a thickness of 16 mm, the skeleton itself was assembled (what a fortune that my father worked in LesTech at that time and could buy cheap waste from their pilot production!). The rear wall was made from 4 mm plywood 4, which was attached on small studs.

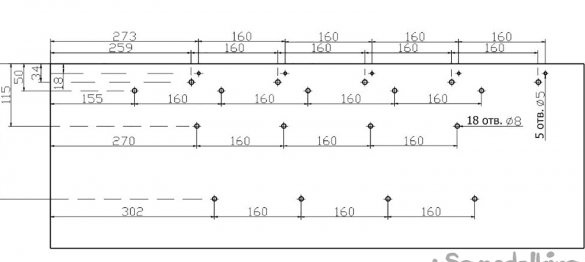

Before you assemble and glue the box, you should mark and drill all the holes in the sides for the doors and crossbars, as well as for dowels. The markup must be carried out very carefully.

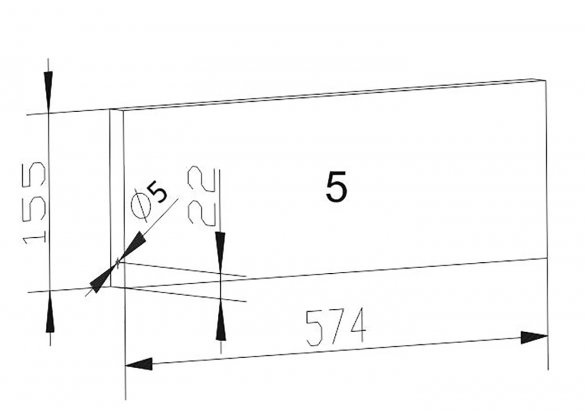

Holes Ø5 mm at a distance of 18 mm from the edge of the through and will subsequently be applied day hinge door hinges. All other holes are blind 8–9 mm deep. They are designed to secure the crossbars and dowels, which serve as limiters for the doors. The other sidewall is marked and drilled mirrored.

As the cross members, dural pipes Ø8 mm and a length of 598 mm were used, which are inserted into the corresponding holes during assembly. Then dowels are fixed on the glue, on which the doors rest in the closed and open positions and the box is assembled.

At the end, the back wall is nailed.

Door manufacturing 6 does not present any particular difficulties. They are made from the same chipboard.

At the ends of the door there are two holes Ø5 mm and a depth of 35 mm (for hinge hinges). Then the handles are attached.

Ordinary rivets 40 mm long were used as hinges. A washer was placed between the door and sidewall to prevent overwriting.

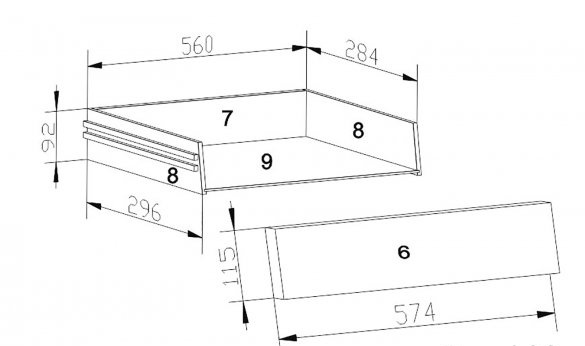

Drawer front panel 6 was made of chipboard 16 mm thick with dimensions of 574x115 mm. Side 8 and back wall 7 made of plywood 10 mm thick.

Duralumin corners were used for assembly, which ensured the structural strength. The bottom was inserted into pre-selected grooves during assembly 9 from plywood 4 mm thick. The box moves on a wooden slide. To ensure this, 2 rails of 10x10 mm were attached to the sides of the box (the rails were attached to the side walls of the bedside table).

At the end, the bedside table was stained (beech color) and covered with furniture lacquer.

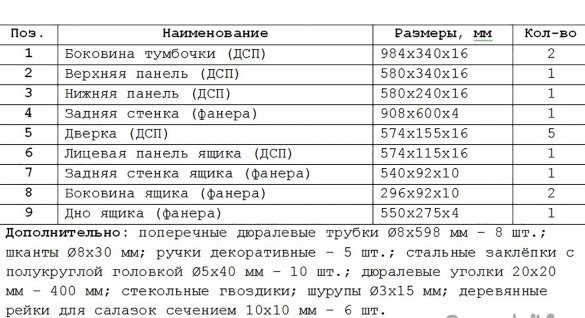

All sizes of parts of the nightstand are given in table.