Perhaps some of you have been cutting glass and know how unusual this process is.

In this article, the author of the TeraFox YouTube channel will tell you how to make a small machine with which to cut glass will be a pleasure.

This project is very simple to manufacture, and does not require complex machines.

Materials

- Building rule

- Sheet chipboard

- Screws, wing nuts

- Glass cutter

- Steel corners

- Wood screws

- Sandpaper.

Instruments, used by the author.

— Orbital sander

— Clamps

— Screwdrivermetal drills

— Bulgariancutting disc

- Square, marker, ruler, vise, screwdriver.

Manufacturing process.

The master will use the old cabinet door as the basis for this machine.

Since the paintwork has cracked for a long time, the author polishes it with an orbital pneumatic machine. Although it is better to use electric, it consumes much less electricity.

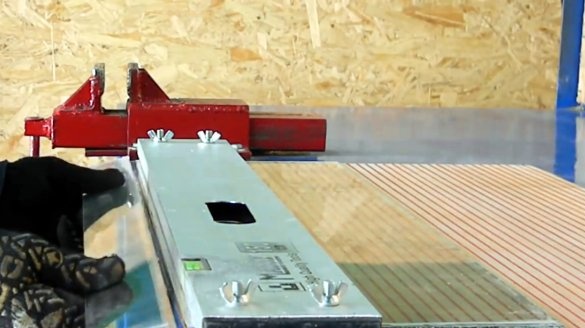

The basis for the guide of this machine will be the old building rule, for which levels are already working incorrectly. Using a screwdriver, the master removes the plastic inserts.

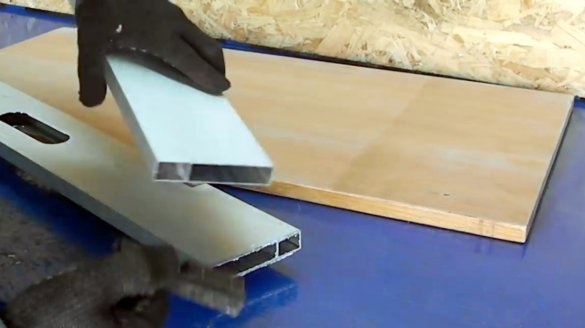

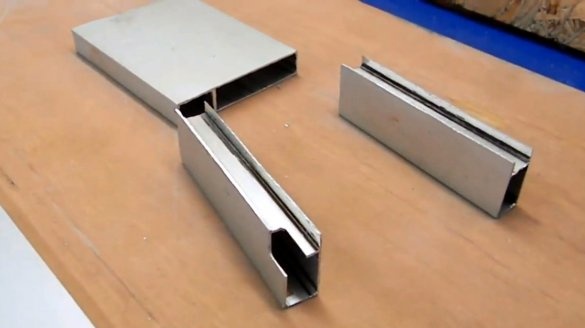

Having retreated 40 mm from each edge of the profile, the master cuts off the excess rules. Another piece 200 mm long is also cut.

Then the stubs are removed from the ends of the rule, and inserted into the remaining long profile.

The master also prepared a couple of corners, and drilled holes in them. Turning the base upside down, he screws the corners to it with screws.

Now, having placed the rule itself under the edge of the base, it drills mating holes in it.

Having inserted M6 screws into the holes of the corners, he welds their caps to the base of the corners.

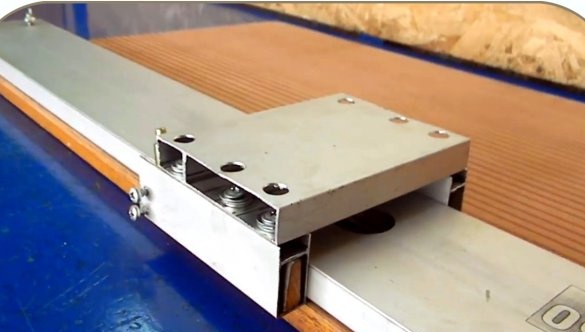

Then the master turns the base over and fixes the rule with wing nuts on it.

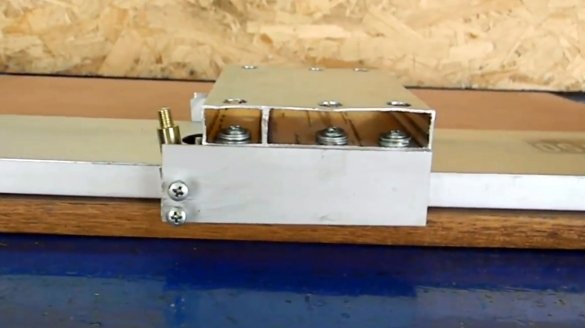

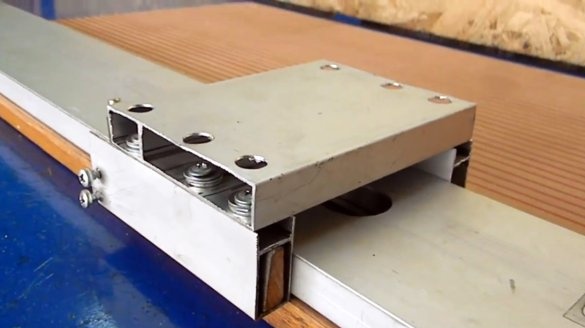

And here are three blanks for the carriage.

In one of the side plates, the master made a special cutout for installing the glass cutter itself.

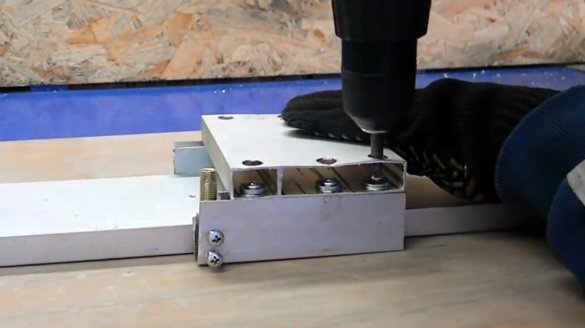

Before fixing the glass cutter in the workpiece, he cut a small wooden plank, it will not allow the tool to shift.

Now, from three parts, the author assembles the carriage itself.

Before starting work, he applies a marking parallel to the edge of the guide with a step of 10 mm.

The author’s first cut turned out to be chipped, the workpiece broke into two parts. This happened because he twice ran the carriage in both directions. This is not necessary, it is enough to perform the cut once.

All further sections turned out better and better. Even a strip with a length of 800 and a width of 10 mm can be made without problems. It is also advisable to use a glass cutter with automatic oil lubrication.

Here is such a simple and unpretentious stanochka you can make yourself almost from the trash.

In a similar way, you can make a machine for cutting tiles.

I thank the author for the simple idea of a glass cutting machine for a workshop!

All good mood, good luck, and interesting ideas!

Author video can be found here.