What a wonderful invention - Dremel. How many all kinds of attachments and attachments to it have been developed. That's just the only one I really missed - a miniature circular saw. There is of course a circular nozzle, but that’s not it.

I decided to make the final decision to make such a prefix after purchasing the Dremel Speed Clic attachment. The drive designed for wood is just perfect. Plywood and thin planks are cut without a single burr.

On the shank of the nozzle you need to cut the thread.

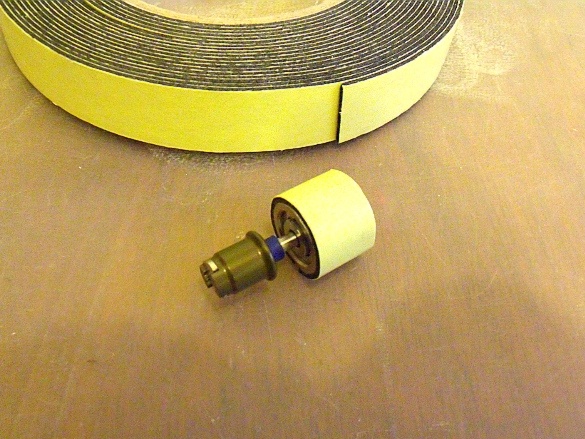

Next, you need a magnetic head holder from the old hard drive. Of the three disassembled disks, only one with the right thread came up to me. If the same is not found, then you can take any and drill a hole for the necessary thread.

Everything superfluous is removed from this part. All that remains is the outer casing with bearings.

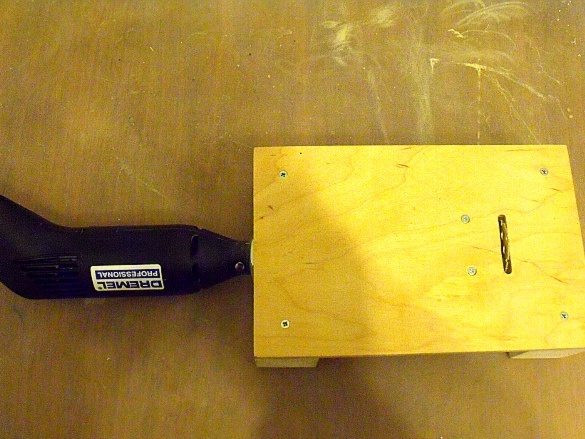

I did not make drawings of this thing. Everything was done by eye and constructed during the manufacturing process. The main details are a plywood rectangle and two bars.

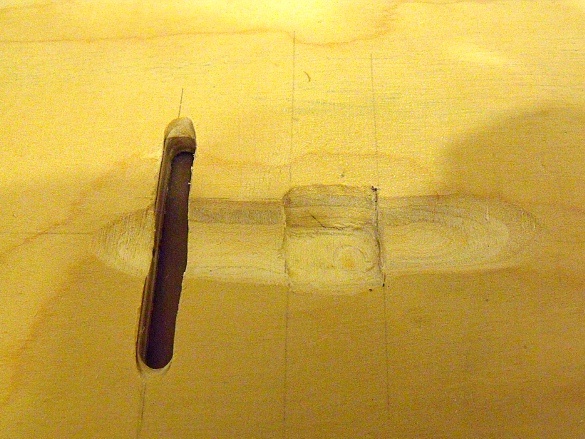

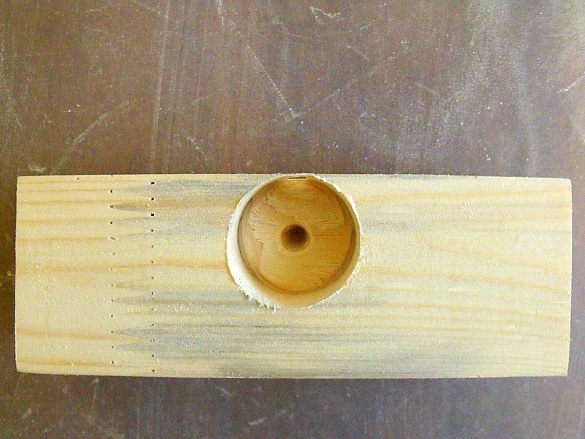

In plywood, a cut is made under the saw and a cavity under the bearing block is milled.

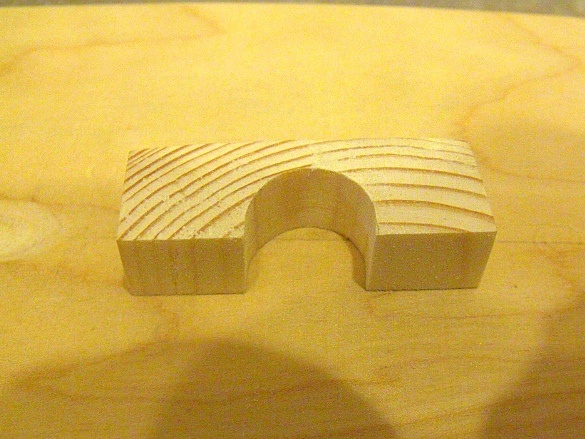

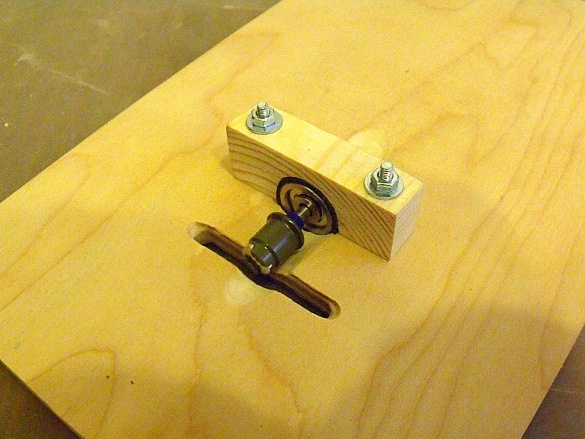

Separately, a bearing block mount is made of wood.

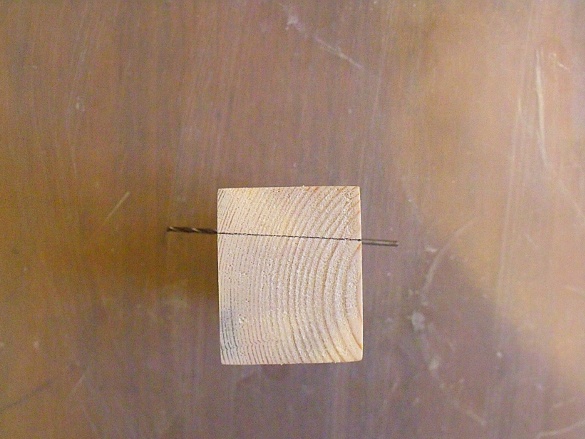

In one of the bars in the center, a 3 mm hole is drilled at an angle of about 5 degrees. This is to ensure that the tool does not protrude above the saw table. If this is not important, then it is possible to greatly facilitate the manufacture and not make a flexible or crankshaft.

Two pen drills of different diameters and holes are made on both sides. First big, then smaller.

A large hole is milled under the nut.

It is better to fix the nut on the sealant. This will reduce vibration.

For better mounting of the bearing block, it is wrapped with double-sided tape with a polyethylene base.

All together attached to a plywood table.

Next, the table is attached to the bars with screws.

Everything is almost done. If you choose a design with a protruding tool, then this can stop. It remains to make an extension cord. For example, from a welding electrode or a long nail.

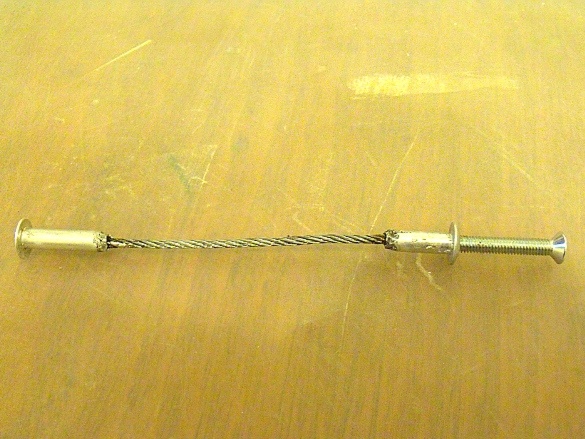

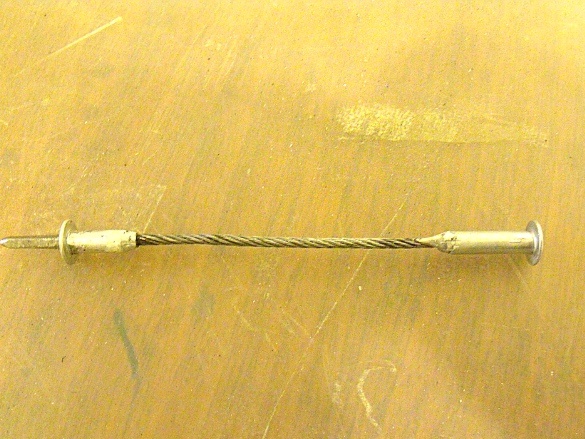

In my case, I had to make a flexible shaft. For it, you can use a metal cable.The one in the photo is not very good. It is twisted to the left, that is, counterclockwise. Therefore, when the tool is running, the cable will unwind. You need to look for a cable with the right twist.

an aluminum rivet body can be used to hold the cable.

A thread is cut inside each rivet. For reliability, the cable inside the rivet is crimped and soldered. A screw is screwed into one of the rivets.

This screw is ground under a square for a standard extension nozzle.

The flexible shaft is ready.

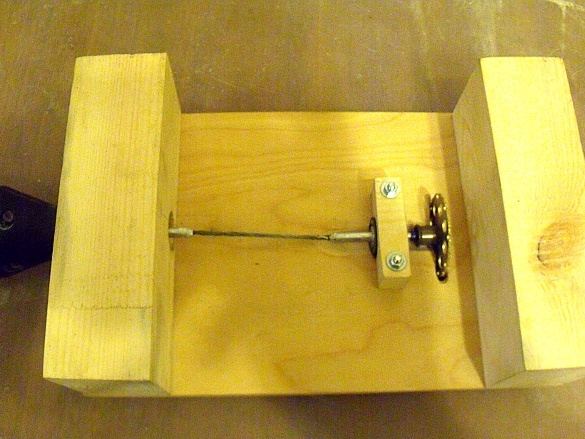

Ready-made console. View from above.

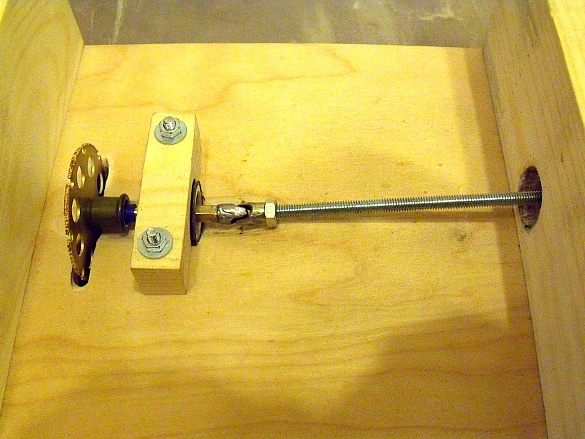

And from the bottom.

With this clamp, you can attach guides and all kinds of accessories to this table.

After several days of operation, I replaced the flexible shaft with a universal joint. I did not do a detailed workout. But I think the photo will be clear. This is a set of parts.

Here's a gimbal turned out. This reduced vibration and allowed to work at high speeds.

Machine video for Dremel: