I bring to your attention a method of casting high-quality sliding sinkers (drop) in home conditions.

For work, we need the following components:

1) Two aluminum plates with a thickness of 1.5-2 cm, can be larger or metal

2) paper clips

3) drills (you’ll pick the diameter yourself)

4) drilling machine or drill

5) lead

6) file

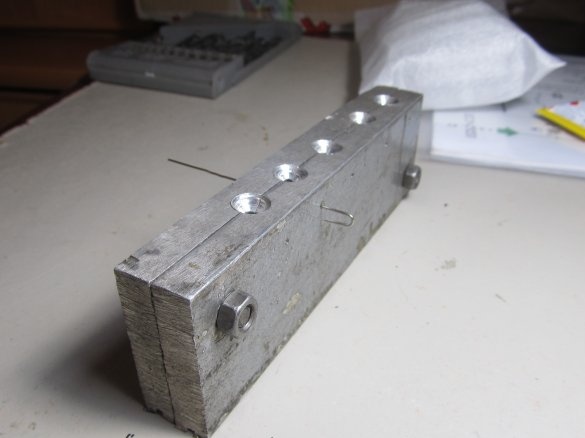

We take our two aluminum plates (metal ones are also possible, but aluminum is easier to process), it is desirable that they be the same in size

First, put the plates together and drill holes for the tightening bolts in the corners.

After we drilled holes for the bolts, we twist the plates together. We take the smallest drill that you have, preferably if the diameter of the drill is a maximum of 2 mm. And drill a row of holes through two plates

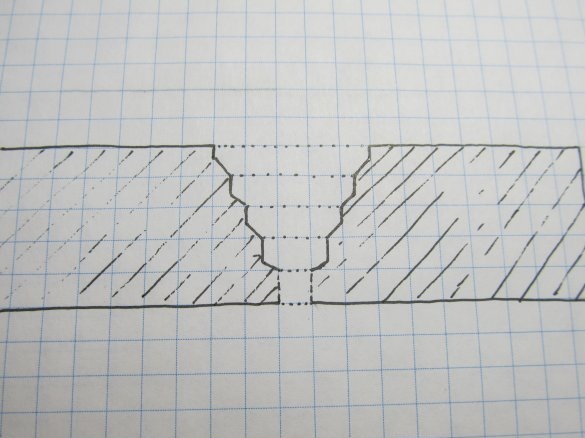

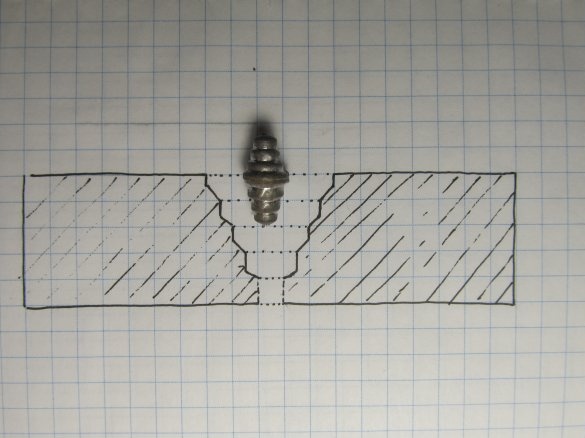

We unwind the plates back, we take drills of different diameters. The diameter of the drills is selected based on what weight and size you need cargo. In my case, I took from 4 mm to 8 mm. We will drill on those planes that are joined together. You need to drill as follows

In the end, you should get it like this

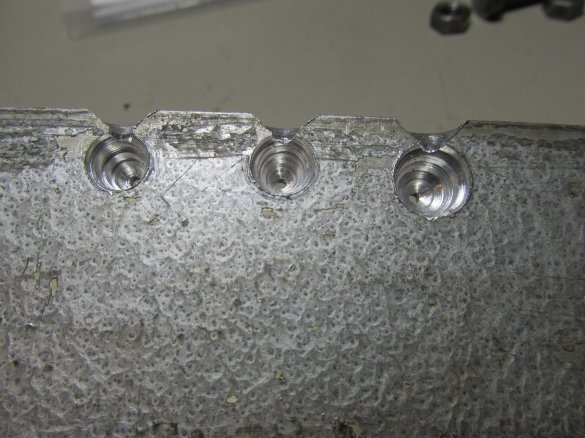

After the molds are ready, you need to drill the filling holes. Putting two forms together (we surely twist) And from the end we drill small holes, then we take a large diameter drill and remove the chamfers (that is, we make a pouring trench)

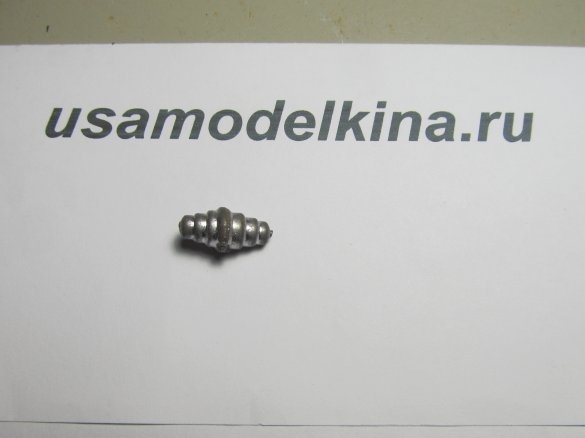

Everything - the form is ready. We take an ordinary paper clip or, insert it into the hole and fill the lead. At the exit, you get beautiful, and very high-quality cargo.