One more easy all-terrain vehicle with side turn. It was built primarily for moving around the forest for hunting, picking berries, mushrooms and the like. In general, a fairly simple version of an all-terrain vehicle for constant travel, and for such cars reliability is first and foremost.

Materials used in the construction of this all-terrain vehicle:

1) Wheels VI-3

2) The diesel engine KM2V80D injection pump, has 2 cylinders and liquid cooling, volume 794 cm3, 16l.s / 3000ob

3) Gearboxes taken from the Salute walk-behind tractor in the amount of two pieces

4) Used belt clutch

5) Chains from IL

6) Headlights from the Belarusian manufacturer

Consider in more detail the progress of construction of the all-terrain vehicle

To begin with, the author decided to make wheels for his all-terrain vehicle. For these purposes, the VI-3 offal from TIM was used, the dimensions of the chambers were 1300 by 530 by 533 mm. The discs were also welded and segments of the conveyor belt were used. The author obtained these materials from an office selling RTI.

Then the author proceeded to the preparation of the Niva axle shafts. They were cut and grooved under a double row with two oil seals, and a normal cover was screwed on, and the author recommends doing such operations even with a normal cornfield, to improve its cross-country ability:

In this photo you can see the tips to the axes:

The 209th bearing was mounted on the tip with a thrust ring, and the flange of the clutch disc from KAMAZ was also installed:

The next step, the author welded the casing, in which the half shaft will be placed:

The result is this design:

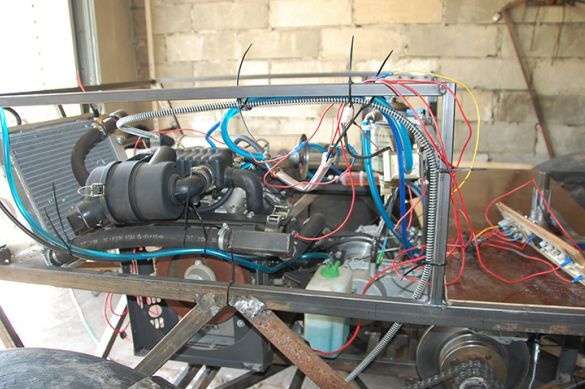

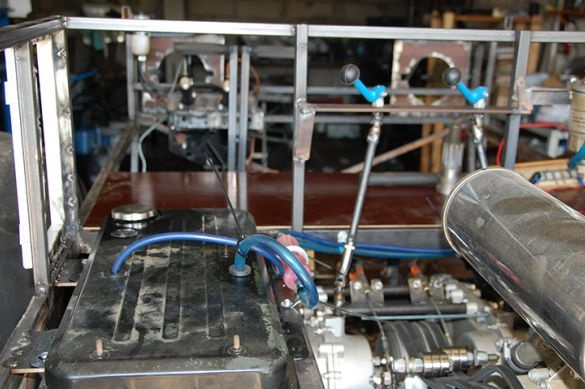

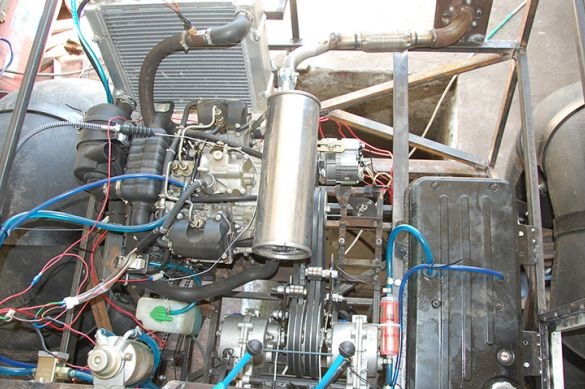

Here we can see the engine frame:

Then the author proceeded to full-scale welding of the frame and mounted it on wheels:

Here you can see the axle mount:

General form:

An engine is installed, as well as a temporary instrument panel is made, in which toggle switches, indicators and the starter button are used:

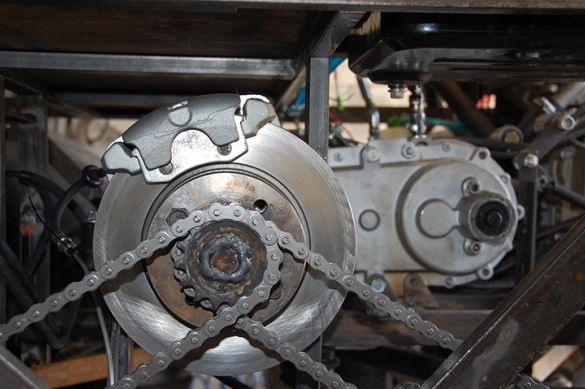

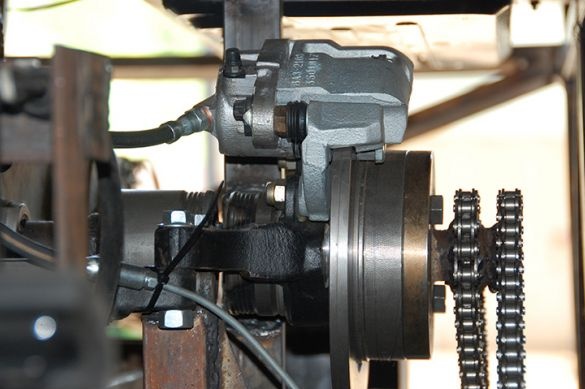

Brakes installed:

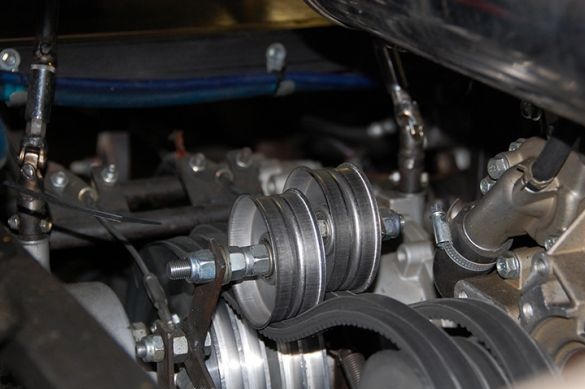

An important detail for structures of this type is the chain tensioner:

Before that, the tensioner was made in a similar way, but it turned out to be too weak:

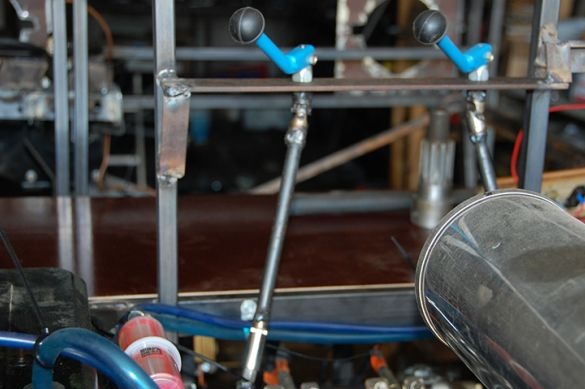

This is how all-terrain vehicle control levers are organized:

And here you can see the clips that tighten the belts:

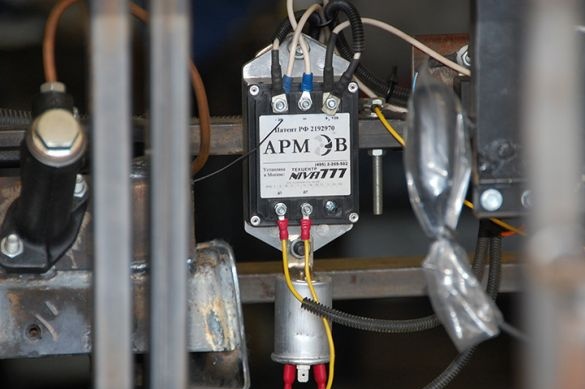

PWM fan controller was used:

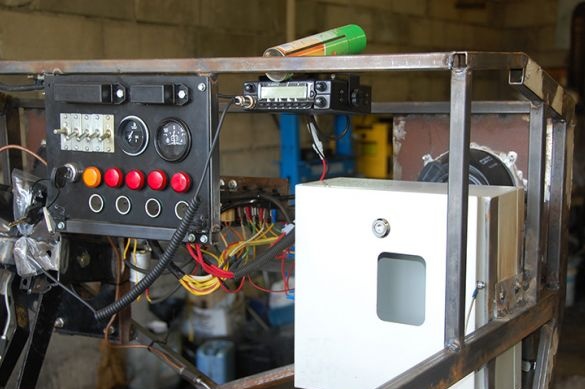

Instruments were installed. Also in the photo you can see the white box, which serves as a glove compartment, inside of which there are two cigarette lighter, as well as lighting.A similar location of the cigarette lighter was to ensure that the charging phone was dry and safe, yet the all-terrain vehicle often travels to not the cleanest places.

The temporary dashboard has been completely replaced by a permanent one:

Here is a rear view, the wire in the photo will be removed:

Here is the exhaust of an all-terrain vehicle:

The wiring is still temporary, but you can already see how the all-terrain vehicle looks from the inside:

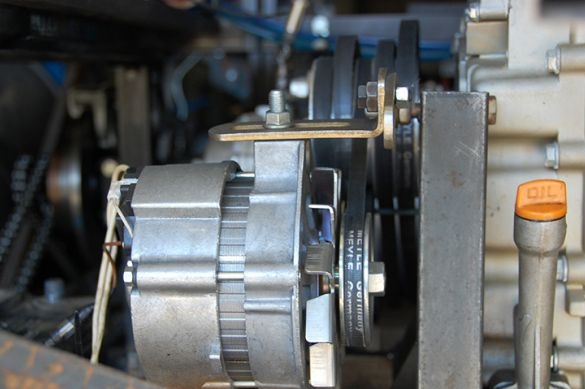

Then the generator was installed:

Photo of the assembled all-terrain vehicle, still without an external casing, behind the levers is the creator of this car:

Regarding the transfer:

The ratio from engine to gearbox is 1: 2

2.8 gear ratio

The mass of the car is about 500 kilograms, which is quite small for an all-terrain vehicle. Thanks to this lightness, even two people can deploy an all-terrain vehicle manually.

Regarding the control of the all-terrain vehicle, there are four pedals, two levers, as well as two handles, it sounds complicated, but in fact it looks easier:

The listing goes from the left edge: Gas, brake to the left side, brake to the right side, gas. Moreover, the gas pedals are doubled.

Left port, right star

Shifting gears starboard, shifting gears starboard, respectively.

Levers have to constantly hold. since fixation in a certain position is not provided, but this does not require physical effort.

The maximum speed of the all-terrain vehicle is about 12 km per hour, this is more than enough in the forest, but I would like to go faster on the road, so the author thought about using pulleys for overdrive.

The dimensions of the master disk are 100, and the slave is two hundred, the author explains these numbers with the simplicity of the work.

Driven by self-made with pulleys made.

The all-terrain vehicle was tested to overcome water obstacles, despite the unfinished frame, it is not bad at all on the water. The shaft with the CV joint is connected by a red-hot bolt by 10, so that the structure holds firmly and does not cut.

Tensioners were made from one branch of the chain, when driving backward or when braking, the clicks of the chain are heard, this is due to the fact that the lower and upper chains sag depending on the direction of movement. A similar thing can be eliminated by installing two roller tensioners.

Further, the author proceeded to cover the frame of the all-terrain vehicle, sealing and painting.

A roof was made, awning. As fasteners, both 0.5 mm self-tapping screws and 0.6 mm rivets were used, then everything was smeared with sealant and primer. Sealant was used a lot.

Hub pockets had to be welded from the bottom with a continuous seam so that the leading edges did not break through the stones.

Speaking of pockets, two options were considered. either separate or solid, respectively. Separate ones increase the clearance between the wheels, which is not bad on the one hand, but on the other hand, when using solid pockets, when moving across a log, the all-terrain vehicle sits on the bottom of the pocket and does not put on the log, but slides, which makes it easier to move the next axis.

Since there will always be water and dirt, it is necessary to install drain plugs with a diameter of 30 mm, which is what the author did.

Frame Assembly:

Photos of the off-road vehicle:

Here you can see the hatch:

Seat and belts:

Soundproofing:

To begin with, the author isolated only the separation of the engine from noise, but this was not enough and noise insulation was used throughout the cabin.

There were also long thoughts about installing a radiator, putting it on the outside is risky, as problems may arise when driving onto steep slopes, so the author decided to leave it inside. its rear location is not the most effective solution, but another has not yet been invented, so the author left it that way.

Test video of the finished off-road vehicle:

After the tests, the following conclusions were made:

The need for a helmet and warm equipment, as protection from branches is not provided for the all-terrain vehicle.

In the video, the wheel pressure of 0.4 is too much, it was decided to pump up the wheels to a maximum of 0.2. It also revealed the need to pack the pump and winch in airtight bags so as not to worry about their condition in the trunk.

The author of the all-terrain vehicle Alexander from the Stupinsky district of the Moscow region with the nickname "Arbuzzz".