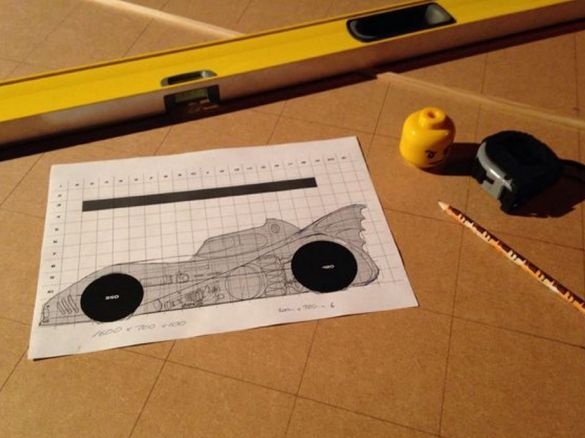

The sketch of the bed was created according to the Micheal Ketaing model, which is one of the original modifications of the Batmobile. The plan is developed using a computer.

To make a Batmobile bed you will need:

- finished sketch;

- MDF sheets - 1220 * 2440 * 218 mm - 2 pcs.;

- a sealant for MDF;

- wooden lining (33 * 33 mm);

- paints;

- fittings;

- crepe tape (masking tape);

- bottom for the bed (IKEA);

- children's mattress.

Batmobile Bed Manufacturing Steps

First stage. Thumbnail Scaling

Calculations will be much more convenient and easier if the sketch is placed on the grid. Each grid cell is square and corresponds to 100 * 100 mm of the real size of the product, that is, the natural dimensions of the Batmobile in the figure are 2500 * 1300 mm. The resulting drawing (a sketch on the background of the grid) needs to be printed, an ordinary A4 sheet will do.

Second phase. Transferring a drawing from a sketch to MDF

You should be prepared for the fact that transferring a drawing to an MDF sheet is a very time-consuming, lengthy and energy-intensive process. After transferring the scaled image from A4 sheet to MDF, it is necessary to indicate in bold line those sections of the drawing on which the holes will be located.

It is enough to transfer the drawing to one MDF sheet and then use it as a template for the second side of the batmobile bed.

The third stage. Cutting sides of a batmobile bed with MDF sheets

To cut the sides of the Batmobile bed according to the contour drawn earlier on the MDF sheet, you need to use a jigsaw. After cutting all the details with a jigsaw, it is imperative to sand all the edges.

To cut holes on the sides of the Batmobile, you must use a specialized machine.

In the course of the work, it was decided to use another sheet of MDF to create a larger volume and realistic design. For the manufacture of wheel arches it is necessary to use the same technique.

Lines should also be cut along the inner edge of the tire.

After that, you need to take this part and use the rotary cutter to cut out the “air intake” of the Batmobile (or rather, that circular part of the bed structure that will imitate it). The last step is to round off the edges of all parts with a jigsaw and sandpaper.

The fourth stage. Production of additional parts for supporting and supporting the main structure

Additional supports to support the main structure must also be made with MDF. These parts will be used to support the batmobile bed and shelf.Each of the details should correspond to the width of the mattress.

The fifth stage. Preparation of structural elements for painting and further staining

Preparation of the details of the Batmobile bed for painting begins with a thorough putty by grouting all irregularities and roughnesses. After that, you need to draw the ribs. If it does not come out smoothly enough, you can use a crepe tape. All parts should be painted in gray and black.

Sixth stage. Assembly of painted and dried parts in a single design

It is important to start assembling the Batmobile bed only with full confidence that all parts are absolutely dry. On the inner side of the parts, it is necessary to fasten the rails so that they support the bottom of the bed. After that, you need to assemble the parts in a single design. At the end of the Batmobile manufacturing process, it is necessary to install a bottom and a mattress.

To increase the effect of the Batmobile, it is recommended to fill with black linen. Any child will be happy to sleep not in an ordinary bed, like everyone else, but in a real Batmobile.