All terrain vehicle with Buckind’s tipping frame design model second one. The all-terrain vehicle was made from considerations of achieving the minimum weight of the structure and achieving the highest possible cross-country ability, even to the detriment of comfort. An all-terrain vehicle is intended for transporting people in the amount of two people as well as cargo up to 200 kilograms at a distance of up to 50 kilometers. At the same time, the all-terrain vehicle must pass any soil at a good speed and even overcome water obstacles, including the ability to swim.

For the manufacture of an all-terrain vehicle of a similar design, the author needed the following materials and details:

1) Internal combustion engine from the car Oka 11113.

2) the steering column from the Niva

3) Nissan Terrano II axles

4) Hydraulic power steering

5) Profile pipe and metal corners

6) TREKOL wheels with dimensions of 1600 by 700 by 635

7) Manual gearbox from a Niva car

Consider in more detail the stages of construction of an all-terrain vehicle.

To begin with, the author decided to weld the frame, as a fundamental part of the machine:

The all-terrain vehicle fracture assembly was designed by Uvata.

Bridges were installed from Nissan with a gear ratio of 4.625, with the rear axle having an LSD lock.

The final drive ratio is 4.1.

The gear ratio on the steering column is 1.53 and 3.6.

The width on the wheels turned out to be two meters 35 centimeters.

The author has not a small experience in the construction of all-terrain vehicles, therefore, he selected such bridges that can withstand the load from such large wheels.

Although he still has some doubts about the reliability of the cardan, as well as the fracture unit in combination with a hydraulic power steering. But such issues are easier to solve in a practical way.

But the author is fully confident in the stable operation of the manual gearbox, since it will be calculated according to standard loads.

Since the weight of some wheels is about 400 kilograms, the all-terrain vehicle itself will weigh about a ton, which is quite a lot. That is why the author decided not to make a cab and kung for this all-terrain vehicle.

In the meantime, the author began to create discs for this all-terrain vehicle.

As can be seen from the photos, a MTZ cylinder was installed, as well as a metering pump. Therefore, in the event of a hydraulic amplifier failure, it will be possible to control the all-terrain vehicle; the pump dispenser allows this, although it is not quite easy.

Another thing in the event of a hose break or oil loss for any other reason, in this case, control and movement on an all-terrain vehicle will be impossible. However, the advantages of such a design overlap with the minuses, in any case for the author of this machine.

The bridges of the all-terrain vehicle were lightened to a weight of just over 70 kilograms. Then mounted on an all-terrain vehicle frame.

The axle shaft has the thinnest place of 30 mm.

The width of the bridge itself along the flanges of the semiaxes turned out to be a couple of centimeters shorter than the similar construction of a cornfield.

The author found on the Internet an announcement about the modernization of the gearbox from the Niva, which he took advantage of. After returning, the gearbox was redone for double row bearings. The author installed and tried the box in test mode, it turned out exactly the results that he achieved, the only minus is that the lock is turned on quite tight.

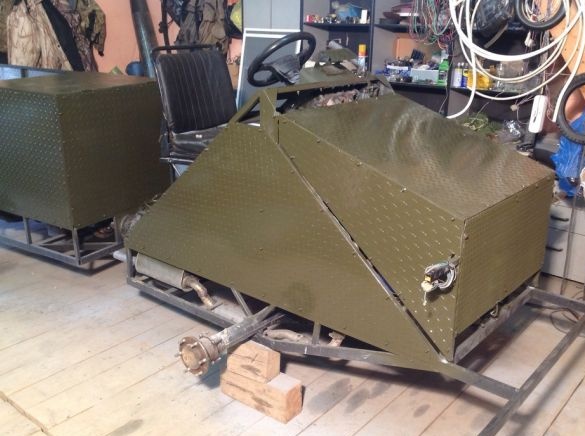

The author proceeded to cover the all-terrain vehicle with sheet metal:

Also on tests, weirdness was noticed in the form of incorrect fan operation. More precisely, the fan simply did not turn on every time when engine loads were on. Since the wiring in the all-terrain vehicle was used from Oka, the author began to look at it, where he drew attention to the sensor, the wire of which broke at the terminal. this was precisely the reason for such a strange behavior of the fan. The breakdown was fixed and the fan started working normally.

Photos from the tests:

Then, paint work was done on the all-terrain vehicle:

Trekol wheels were installed on the all-terrain vehicle, after installation on the all-terrain vehicle and pumping them to a pressure of 0.1, the wheel sizes were 1470 by 680. When pumping them to a pressure of 0.2, the wheel height became equal to 1500.

After riding through the mud, the author noticed that dirt from such high wheels does not fly weakly on the car itself, as well as on the driver, so he still thought about installing the cab, although this will add to the weight of the all-terrain vehicle design.

And there are no complaints for rubber, because the reel, ground clearance and driving confidence in the snow are great.

The minimum speed of the all-terrain vehicle is 1 km per hour. The fourth gear can only be used on a solid and level surface, so the author thought about changing the gear ratio of the main pair to 4.5 in exchange for the old 4.1. Perhaps then using the fourth gear will be more appropriate.

The hydraulic control works fine, only for some reason the steering wheel cannot be turned sharply, as if the steering wheel abuts against something. The source of this has not yet been established by the author. In the quiet mode, the control does not require absolutely any load from the author, the steering wheel is spinning with one finger.

Photos of the off-road vehicle:

The author of the all-terrain vehicle: Vladimir with the nickname "Bolodya" from the Khanty-Mansi Autonomous Okrug-Ugra.