This all-terrain vehicle was assembled by the author in 2015. It was made for hunting and fishing, so special attention was paid to comfort.

To create this all-terrain vehicle, the author used the following materials and details:

1) Lifan internal combustion engine with starter.

2) a generator from an oka car

3) 2 headlights from a complex of 4 ex-halogen lamps of 55 watts each.

4) gearbox from a classic vase

5) star 13, 47 teeth

6) chain in increments of 19.05

7) 205 bearings

8) steering knuckle from a UAZ car

9) 40 to 20 profile at 1.5, 20x20, 15X15, 60x30x2

10) aluminum sheets 1.2 mm

11) polycarbonate 4 mm

12) id-p284 wheels of size 1100 by 450 by 508

13) 1.2 mm iron barrel

14) m6 bolts

15) driveshafts from vaz 2107

Consider in more detail the main components of the design of the all-terrain vehicle.

Since the native generator produces 10-15 watts, the generator from Oka was installed instead of it, using an additional stream to the engine pulley.

As headlights at night, two headlights were installed on an all-terrain vehicle from complexes of four 55-watt halogen lamps.

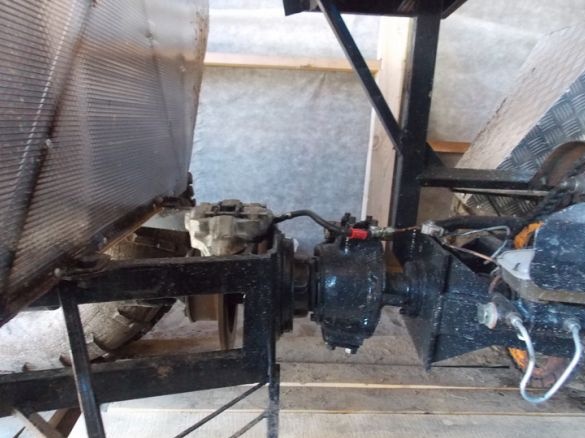

Pictures of all-terrain vehicle designs:

On the engine itself there is a four-grooved pulley for profile A, whose length is 1280 mm. Three belts go to the large pulley, which is directed to the gearbox. The pulley diameters on the engine and on the box are 105 mm and 265 mm, respectively. and at the exit from the box there is a star with 13 teeth, from which there is a chain transmission to a star of 47 teeth. The star itself is mounted on two 205 bearings, and two pendant driveshafts from a VAZ classic were used to secure it. Next, the transmission from the cardans goes to the front axle of the all-terrain vehicle, and on the other hand has a mount to the exit of the steering knuckle. The steering knuckle from the UAZ with the built-in grenade from the Niva car was used as a node for breaking the all-terrain vehicle frames.

At the exit of the turning fist, a brake disc with a caliper from the vases is installed, and the main brake disc is from the vases 2108. From it there is a driveshaft to the rear axle of the all-terrain vehicle. The bridges were used from a classic vase and have a gear ratio of 4.3.

Also on the all-terrain vehicle mounted steering rack from frets 99, which is spliced with traction from Oise.

The all-terrain vehicle frame was made of a 60 by 30 profile pipe with a thickness of 2 mm. the front frame is single-level and rigidly welded into the bridges of the all-terrain vehicle. The length of the frame is 90 centimeters. The rear frame is made of a profile measuring 40 by 20 and a thickness of 1.2 mm.The rear frame itself is made in a two-level version and is also welded to the bridges of the all-terrain vehicle.

The wings of the all-terrain vehicle were trimmed using aluminum sheets 1.5 mm thick. To strengthen the structures, a profile of 15 by 15 was used. The frontal sheathing is made of polycarbonate 3 mm thick.

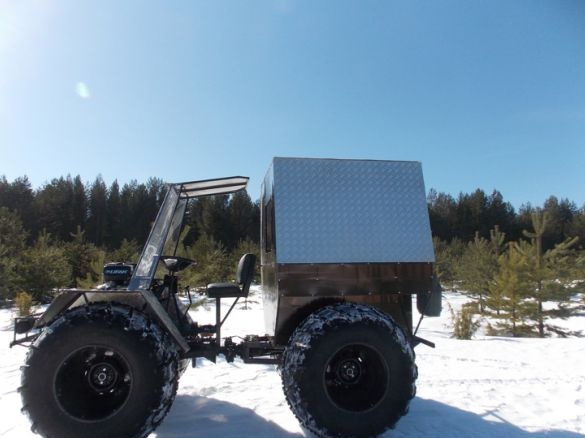

Photos of the kung and outer skin:

Then, the author began manufacturing a kung frame from a profile pipe measuring 20 by 20 and 15 by 15.

Kung was also sheathed with aluminum 1.2 mm thick and cellular polycarbonate 4 mm thick.

After improvements with the all-terrain vehicle frame and casing, the combat wheels were installed on the machine: ragged chamber id-p284 sized 1100 by 450 by 508.

The width of the disks for these wheels is 410 mm; therefore, they were closed by a barrel and turned out to weigh under 16 kilograms. The barrel is made of 1.2 mm iron and 1.5 mm cones.

The width of the all-terrain vehicle itself was 185 centimeters, and the length was about three and a half meters. The total weight of the car is at least 600 kilograms, and the maximum speed is 20 kilometers per hour.

Of the minuses of the design, there is an incorrect weight distribution, which will be partially compensated by the installation of the trunk and the correct distribution of cargo. Also on the wings of the all-terrain vehicle there are special fasteners for backpacks. the kung of the all-terrain vehicle was still quite high, the possibility of dismantling the upper structures by removing the m6 bolts is being considered.

Polycarbonate, from which the lining is made, bends rather easily and is cut by a grinder and fastens to self-tapping screws, which is quite convenient and does not take much effort.

Further, regarding the minuses of the all-terrain vehicle design: since the engine is raised too high, warm air goes directly to the driver, which is nice, but the exhaust fumes come with the same warm air and also directly to the driver, which is not nice.

The author tried to solve this problem with aluminum corrugation, but the engine began to experience stress. After the corrugation burned out, it was dismantled from the all-terrain vehicle. Therefore, a search for a solution is still underway, although the author really does not want to redo the entire exhaust structure or reinstall the engine below.

Also, due to little experience in the construction of such units, the chain is stretched due to the plate on which the gearbox is installed, the problem is that with this approach, simultaneous tensioning of the belts is necessary, which is inconvenient. The solution is considered through a rigid fastening of this element, or the installation of shock absorbers.

Another drawback of the design is the all-terrain vehicle wings, they are made with bevels and therefore all dirt is thrown right under them, the author also seeks a solution, preferably without the need to expand the edge.

In more detail regarding the construction of bridges.

two driveshafts from vaz 2107 were taken, as well as part of the suspension bridge. Excess iron was removed, in particular the slotted part. Then, turning work was done with the thickening of the thickening of the propeller shaft pipe. The diameter is adjusted to the inner diameter of the star’s body from the Izh motorcycle.

The result is a kind of workpiece blank, a feature of which is to install on a hot, for greater alignment of the shafts. It is important.

All rubber is simply cut off from the suspension bridge enclosures and the iron is freed.

After we weld the trims to the bodies. And put on the forks. And from them to the front axle and to the steering knuckle.

Photos of the off-road vehicle:

The author of the all-terrain vehicle: Sergey with the nickname Sergey "Sergey Belorukov" from the Arkhangelsk region.