Those people who have their own plots in which they are engaged in growing crops dream of a greenhouse that would not require constant attention to it, capital.

The author of this master class shares with you his experience in the manufacture of such a greenhouse, built thoroughly and permanently. From the corner and polycarbonate.

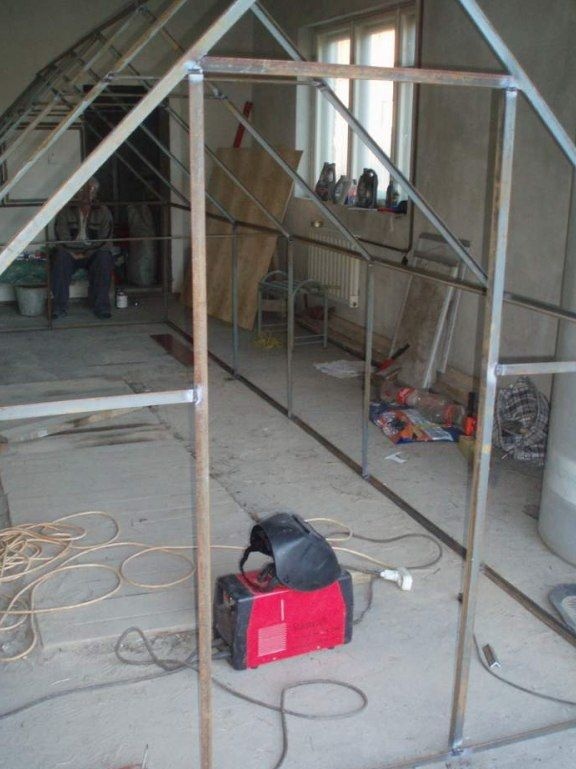

To begin with, a rectangular strapping frame is prepared, the dimensions of which are 2 * 6 m.

Material - angle 25 mm.

Next, the elements of the roof-corners are prepared. They need to be cut at an angle.

The parts are fastened together by welding. After the spare parts for the roof are ready, begins to mount them on the frame of the greenhouse.

After completing this procedure, we prepare the lower harness and supports for connecting the lower and upper parts of the greenhouse. Mounts.

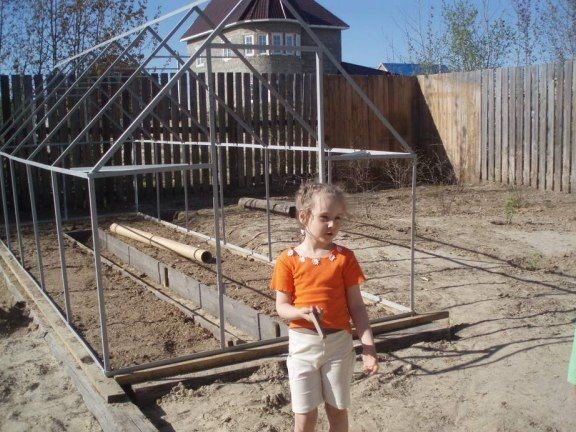

A window is made in the end part to ventilate the greenhouse.

The door is made at the next end.

Already finished frame.

The greenhouse frame is treated with a primer. Holes are drilled around the perimeter of the frame for fastening polycarbonate.

Next, the frame is installed in the selected location.

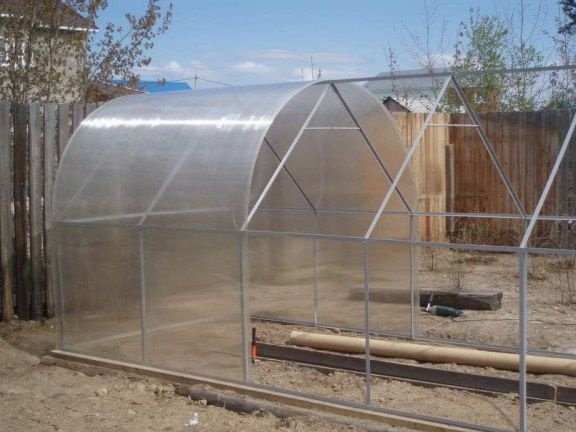

And the lining of the greenhouse frame begins with polycarbonate.

The door is sheathed with a small margin for a more tight seal.

And the capital greenhouse, which will serve you for more than one year, is completely ready.