The press was made for packaging cardboard, plastic bottles and other second raw materials.

Compressed cardboard bale weight up to 250 kg

Maximum force 20 tons

Bale weight of pressed plastic bottles up to 110kg

Bale sizes 900 * 700 * 1000

Press height excluding hydraulic cylinders 2 m

Weight approx. 700 kg

Based on this press, it is easy to make a press of smaller size and effort.

This is done by reducing and facilitating the design, reducing the pressure in the hydraulic system, or replacing the cylinders with cylinders with a smaller piston diameter.

It works from a hydraulic station that can be installed on it or be remote.

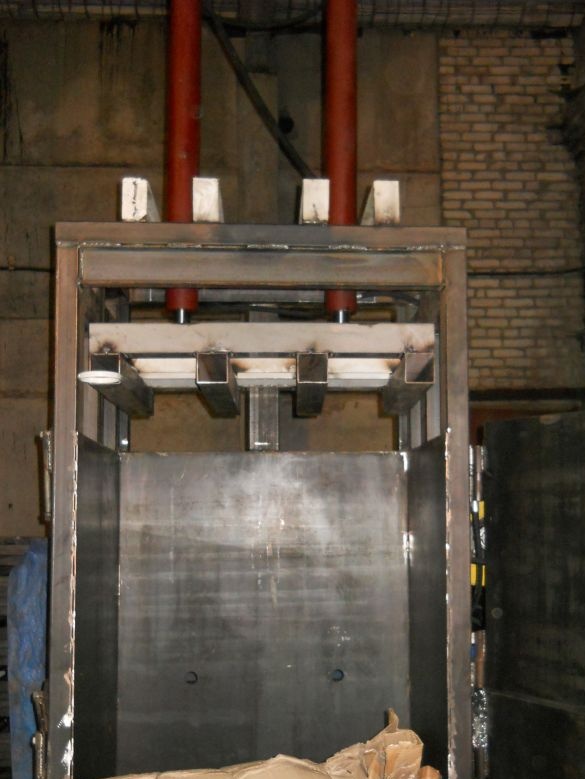

The frame is welded from a steel profile pipe 60 * 100

All intermediate spaces are protected by a smaller profile pipe.

With nutria sheathed with sheet metal with a thickness of at least 3 mm.

On the floor there is a channel for pulling the strapping wire or rope.

Press paw is made of profile pipe 60 * 60.

There are two doors in front. Lower for unloading the finished bale, upper for loading and unloading of raw materials. Doors are mounted on turned hinges with a diameter of 45 mm.

If the press is used for pressing cardboard, then metal squares are welded to the lower door. They are needed to prevent the cardboard from lifting when it is loaded.

Doors are fixed for latches type hook cut out of sheet steel 10 mm thick.

When searching for hydraulic cylinders, specialized, custom-made, and agricultural machinery were considered.

Specialized are very expensive and have a long delivery time.

Custom ones are even more expensive and also have a long production time.

We stopped on cylinders from agricultural machinery. They are easily accessible and not expensive and in case of repair, repair kits are available. But they went through refinement. Make and weld installation flanges.

The hydrodistributor and high pressure hoses are also taken common from agricultural machinery.

The two-cylinder system is selected due to the lack of an additional guide.

The cylinders also work in pairs, which reduces their wear.

The stroke length of the hydraulic cylinders is 1 meter. The piston diameter is 85 mm.

Standard swivel mounts on the cylinder rods are sawn off and they are rigidly welded to the presser foot.

By plasma cutting, flanges are made for attaching the cylinders to the press. Only four pieces.

Two pieces are thoroughly welded to the lower parts of the cylinders, the other two are reciprocal to the press. During installation, everything is connected with bolts m 12 in an amount of 16 pieces.

With high-pressure hoses, hydraulic cylinders are connected in parallel through tees and connected to a P-40 type directional control valve.

In order to increase safety, the valve is selected without locking in the extreme positions.

If you release the lever, the cylinders will stop.

The distributor, in turn, is connected by high-pressure hoses to a hydraulic high-pressure pumping station.

If it is planned to extrude plastic bottles, then a throttle is installed in the hydraulic system between the distributor and the cylinders. It must be adjusted to the nominal fluid flow during commissioning.

It prevents hydra shocks when raising the paws.

The control valve includes a relief valve. By adjusting this valve, the maximum working pressure is set.

Since it is possible to work in open areas, the entire structure is coated with a primer and painted with paint resistant to atmospheric precipitation.

Work on the press as follows

In the channel on the floor, strapping material is laid one end with a margin remains outside, the other ends are pulled through holes in the rear wall.

The bottom door closes.

At the bottom lies the packaging material (cloth, cardboard or other)

The raw material for pressing is laid

The upper door closes and the initial pressing is performed.

The paw rises and the material is loaded.

This is repeated until a bale of the right size is formed.

Before the last pressing, packaging material is laid on top.

Finishing is done.

Both doors open, through the paw from the holes in the rear wall the ends of the strapping material are pulled and connected (bonded, riveted or otherwise) linking the bale.

The paw of the press rises and then the finished bale can be pulled out.

Pressing into a pile of packaging cardboard raises its cost up to two times.

The volume is reduced to 5 times, which is very economically beneficial for transportation.

Pressing into a bale of PET bottles raises up to 5 times.

The volume decreases to 15 times, which also has a very beneficial effect on transportation.

Bales are also much more convenient for loading and unloading.

Then this recyclable material is sent to the plants for processing.