The question arose how to show the products that we produce so that it is clear and memorable.

It was not possible to bring ready-made equipment for display to a potential client. Large dimensions and weight more than a ton. Moreover, the meetings took place mainly in office centers. Not much is ready to come to meet with us for production.

Paper catalogs did not fit. There are many different manufacturers, they are lost and that the main thing is not remembered at all.

The videos also did not make any impression.

It was decided to make a working model a press that you can take with you and show the principle of action.

The result exceeded all expectations! Everyone paid attention to this model, remembered and then discussed for a long time. The task was completed. He worked very noisily and all the workers in the neighboring rooms gathered for this noise. It turned out to be very spectacular, although a small show.

This device easily compresses with potential customers plastic bags, all kinds of cardboard boxes. The developed effort, despite the toy performance of more than 100kg. It also presses empty beer cans very effectively.

The scale was not adjusted, the emphasis was put on that the model was wearable and resembled the original.

The frame, doors and paw are welded from a metal profile 15 * 15.

Doors and inner walls are lined with 1mm metal.

Doors are welded to furniture hinges.

To lock the doors on the screws installed furniture hinges.

All metal structures are sanded and painted in black enamel.

Since it was problematic and very expensive to make a working hydraulic system of such a small size and, most importantly, for a long time, a decision was made in favor of installing a pneumatic system. Moreover, the units are similar to hydraulic ones and perform similar functions.

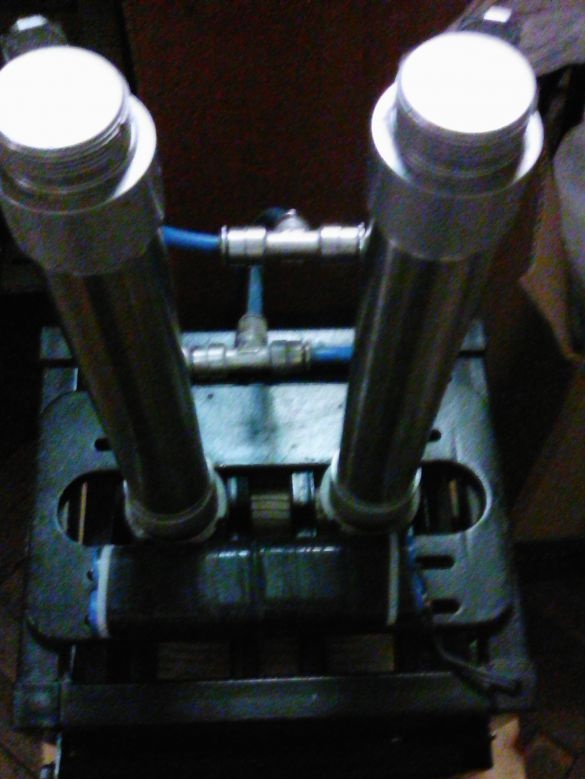

Two pneumatic cylinders with a piston diameter of 30 mm and a stroke of 200 mm are mounted on top and the rods are connected to the presser foot by means of standard threaded connections.

Inductors with collet fittings are installed on cylinders for smooth running.

Further, using tees, the cylinders are connected in parallel.

And then connected to the valve.

A manually operated valve was not found.

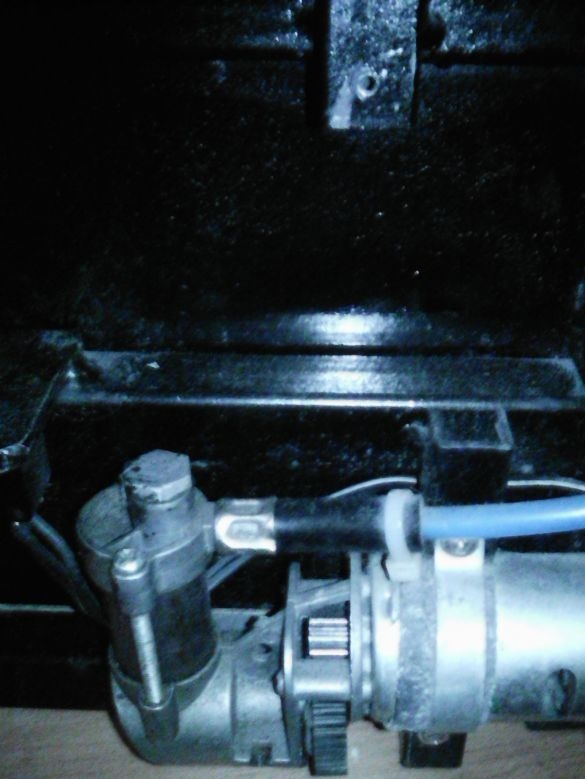

I had to redo the bi-stable distributor with electric control.

To do this, the electric coils are removed and end plates are made and installed instead, the excess holes are plugged, the rod is elongated.

If you move the stem manually, you can control the pneumatic cylinders.

As an air compressor, an automobile was taken for inflation of tires.

Case and excess equipment removed.

Tests with a compressor having a rather large internal volume show: the pressure does not rise above 8 kg2, and such a regimen was transferred without any pain for a minute. The duty cycle is 20 seconds. Based on this, neither a pressure relief valve nor a pressure switch was installed.

The remaining unit is mounted on threaded connections to the model body. The air supply hose is connected respectively to the air distributor.

The air receiver was decided not to use. The first saves weight and space, the second because of the short duration of the work and not high requirements for speed and smooth movements, its presence is not necessary.

A power switch is installed nearby for operational control.

The compressor is powered by a lithium battery having a nominal voltage of 15 volts and a capacity of 2500 mAh. This battery has all the necessary protections.

The battery capacity is enough to organize more than 10 impressions.

It is infected by an external charger

The battery voltage is not much higher than the compressor nominal, but this does not cause problems due to the short-term operation mode.

Work with this model as follows:

1. Transfer the air distributor to the lifting position.

2. Turn on the compressor power for the time necessary to fully raise the paw.

3. Open both doors and load material for pressing (film, cardboard, or something else)

4. Close the doors, put the distributor in the lowering position of the legs and turn on the compressor for the time necessary for pressing (about 20 seconds).

If necessary, pressing cycle