I think that many who work with hot-melt adhesive have pieces, trimming and working off hot-melt rods. You have to throw them away, but new rods cost money. With this tricky device, you can save money and waste glue.

I saw a comment on the glue gun from USB in the contact in the group, someone asked me to figure out how to collect the spent glue into the rods. I decided to implement the idea)

Video of step-by-step assembly and operation of the device for familiarization.

We will need:

1. A part of parts from a soldering iron from a fixed price for 60 rubles.

1.1. Nichrome wire

1.2. Tube shaped metal part

1.3. Fiberglass

1.4. 3 screws

2.2 copper wiring

3. Bank from soda

4. Foil of medium density (can also be baked in the oven)

5. USB cable

6. Electrical tape

7. Wooden plate (you can also cardboard from large boxes)

8. Power supply 5V 2A

From the tools:

1. Pliers

2. Scissors

3. Screwdriver

Step 1.

We disassemble the soldering iron and leave the nichrome wire (it is better to take another, this is not high-quality), a metal tube and fiberglass.

Step 2

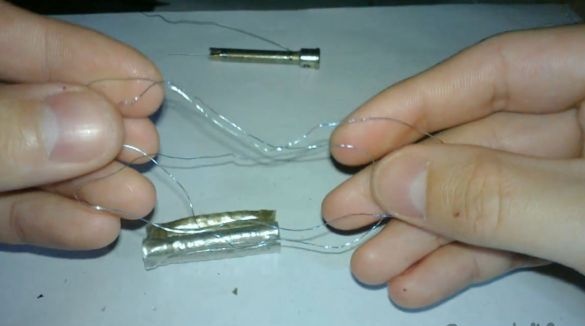

We wind the glass fabric on the tube as shown in the photo and on top we wind several turns of nichrome wire (four is enough) and fix it on the edges with two pieces of the same wire so that it is stretched.

Step 3

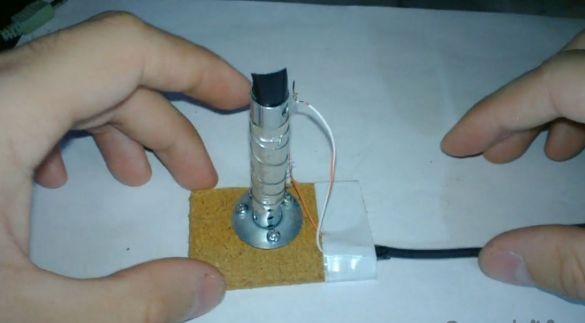

We take a flat wooden plank (4cm x 7cm) or thick cardboard and fix a metal tube on it with three screws, as shown in the photo.

Step 4

We fasten the USB plug to the board with electrical tape (you can also use hot-melt adhesive) and fasten the wires to the nichrome wire.

Step 5

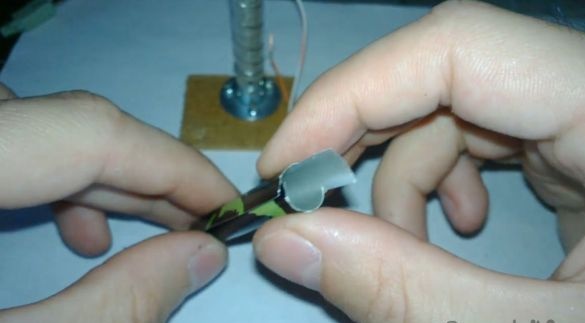

Initially, a metal tube with a diameter of 10mm, and we need to get 7mm rods. We cut the plate 8 cm long and 5 cm wide from the aluminum can and roll it into the tube by putting the core of hot melt glue inside. At one end, cut the tube, leaving a small tongue, for which we can extend it if necessary. This tube is necessary to reduce the diameter of the hole and prevent deformation of the mold for remelting of the foil.

Step 6

We insert the resulting tube all the way into the previously prepared design, as shown in the photo.

Step 7

We take the foil 10 cm long and 7 cm wide and roll it into the tube, putting the core of hot melt glue inside. This will be our form for melting hot-melt glue pieces.One end of the resulting tube must be bent well so that the molten glue does not adhere to the plank and does not spread at the bottom of the metal tube.

Step 8

Insert the mold for remelting in the resulting design until it stops. And you can start remelting.

Cut the remaining pieces of hot-melt adhesive so that they crawl into the tube. We throw them inside and connect the device to power.

The process of remelting one 10 cm rod lasts no more than 2-3 minutes. And the whole process of processing from heating the device to cooling molds with melted adhesive takes 5-6 minutes.

In the process of remelting, it is necessary to slightly tamp the pieces of glue in the tube so that the core is solid and with the smallest number of bubbles inside.

The resulting rods are identical in diameter (7mm) to the new ones.

Several recycled rods are very easy to put together. It is enough to heat the edges with a lighter and attach them to each other, the glue will do its job.

I hope someone comes in handy this homemade.

I did not come up with a short name for the device. Who has thoughts on this, share in the comments. Together we come up with the name)