Cordless mini drills and drills are not cheap and sometimes, for small jobs, I do not want to overpay for high power and brand of the tool. I decided to try to make a similar tool do it yourself and not at great cost.

Video of assembly and test instrument for familiarization

We will need:

1. Cheap glue gun from a fixed price (60 rubles)

2. 2 rechargeable batteries of 18650 of the same capacity ()

3. Switch from the drive of the old music center

4. Connector and 4mm plug for connecting power (or any other)

5. Motor 6 - 12V ()

6. Not an expensive collet in a set ()

7. Heat Shrink 3mm

8. Copper wiring

9. Hot melt adhesive

10. Scotch tape

11. Electrical tape

From the tools:

1. Long nose pliers or pliers

2. Stationery knife

3. Glue gun

4. Screwdriver

5. Soldering iron

Step 1

We need a glue gun from a fixed price, it is not expensive and not a pity to put into action. Maybe someone has such an old one, they often fail.

We disassemble it, pull out all the insides (maybe later for which they will come in handy) and leave only the case.

I chose this particular case due to the fact that the motor fits well if you cut a place for it, low cost and ease of further operation. You don’t have to make a pen and the case from anything, almost done already.

Step 2

I ordered a motor (), which is often used in budget drills, is not expensive.

You can try to get one of the old printers or MFPs, also suitable.

Step 3

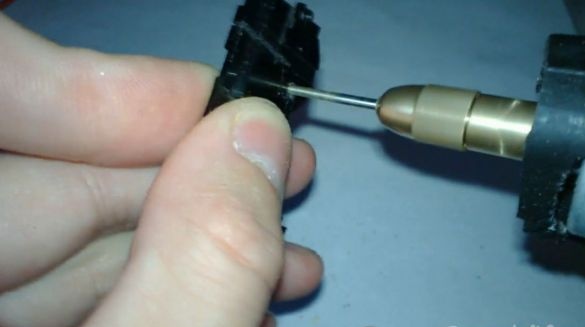

We cut out a place for the motor in the body from the glue gun so that there are legs for fixing the two halves with self-tapping screws, the motor just fits in with their location.

You can cut with a clerical knife, but carefully, the main thing is not to overdo it and not break the case.

I cut holes by gradually adjusting it to the size of the motor, cutting it a bit.

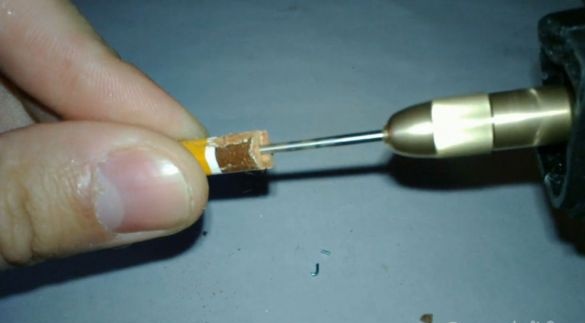

The shaft should be centered as in the photo.

Very well located ventilation holes.

Step 4

We do the same with the other half of the case and connect for fitting.

After fitting the housing to the motor, it is necessary to trim part of the housing where the collet will be mounted on the shaft. It should turn out like in the photo. Cut to the fixing legs, we need them.

Step 5

Next, you need to choose a connector for connecting power. I used a 4mm jack from an old charger extension cord.

I decided to install it in the hole where the glue sticks were fed.

Cut a little with a clerical knife and now it holds tight. Then we fix it on one half with hot-melt adhesive for reliability.

Step 6

From the old drive of the musical center, after its analysis, there was such a switch. Used to turn off the motor when the drive tray was closing.

Very well suited in size to the body and there is an eye for a self-tapping screw or bolt. In addition, a spring is installed in it, which returns the lever to its original position.

In the holder where the glue gun button was installed, fill it with hot glue and put our switch in place with a self-tapping screw in the eye. After the adhesive cools down, the switch will be well fixed. For reliability, the switch can also be fixed on the inside of the case with hot-melt adhesive.

We cut the excess on the second half to fit the size of the switch and combine both halves to view the result. It should turn out like in the photo.

Step 7

Next, we place the motor in the prepared place, we fix the connector for the power supply with hot-melt adhesive and solder the wiring.

At the expense of connecting wires.

In the connector I took, the polarity is as follows:

+ located inside the connector (light brown wire lead)

- is located outside the connector (black wire output)

Plus from the power supply (light brown wire), I connected to the plus of the motor (usually marked in red) directly. The minus from the power supply (black wire) was soldered to the switch and from the switch (dark brown) led to the minus of the motor. Places of adhesion insulated with heat shrink 3mm.

With this connection, the motor shaft will rotate clockwise, for the possibility of using drilling, since there is no implemented system for reversing the direction of rotation of the motor.

We twist the screws fixing the case and on this design is ready.

Due to the large size of the connector, I made it a little sticking out. This does not bother me at all, but you need to select the connector for yourself.

Step 8

Now let's start making a battery for a mini drill.

Normal voltage for the motor is not loading and does not overheat it 6-10V.

Initially, I wanted to use one 18650 rechargeable battery placed in the handle of the case and a step-up voltage converter. It will allow 4V to increase to 10V. Delivery is delayed, then I will finish it as planned.

And now I will use 2 18650 batteries connected in series.

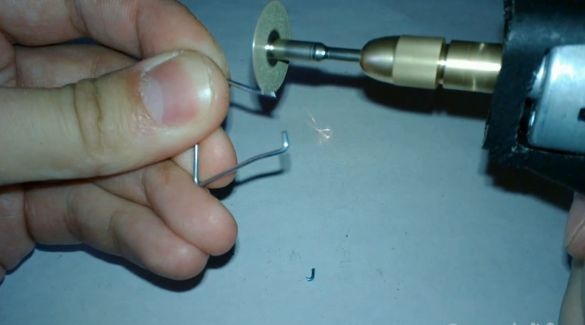

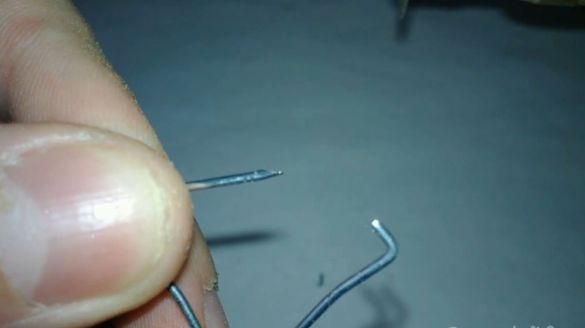

On one side, they are connected by a copper wire twisted into spirals on both sides, and on the other, a plug is soldered to connect to a mini drill.

The total voltage of the two batteries is 7.6-8V, which is enough for small jobs.

They will have to be charged separately or using the module to charge two 18650 batteries () in series.

I fixed the batteries on the top or bottom of the handle, as it is convenient for anyone. It’s more convenient for me from above.

Getting to the test

In the video, I conducted several tests of work. There is enough power for small jobs.

Even an old drill does a good job.

Wood, plastic and circuit board from the camera drills confidently.

Sawing wood and plastic like a knife without a break. Not stuck.

The diamond nozzle handles metal confidently and quickly.

In the future I will improve the design and power.

I hope the article was useful and will help someone in creating such homemade.