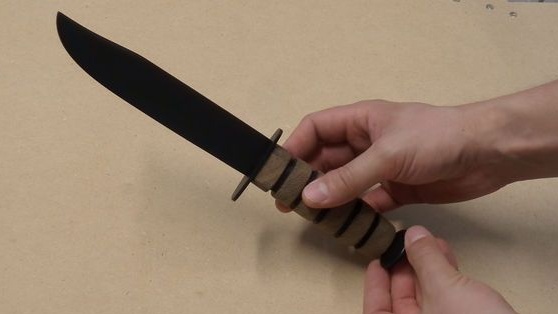

If you have an old saw blade, you can make a great knife out of it. The author used a 16-inch drive for such purposes. With such a knife it will not be scary to go camping, and it’s not a shame to give a present. When creating, the most important thing is to adhere to safety rules, since we are talking about metalworking.

Materials and tools for homemade:

- saw blade 16 inches;

- grinder;

- belt grinding machine;

- felt-tip pen;

- whetted;

- wood and wood cutting tools to create pens;

- drill or drilling machine;

- matte black paint;

- epoxy;

- handle oil and more.

The process of making a knife:

Step one. Cut out the contour

First you need to come up with and find the shape of the blade, and then transfer to disk and cut.

Step Two Coarse rough grinding

Now the author polishes the blade on the sharpener, asking him the main form.

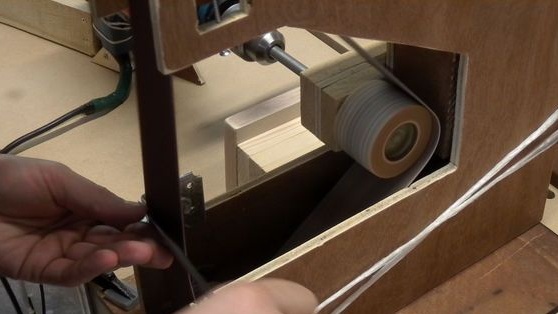

Step Three Belt machine

On the belt grinder, the desired blade angle is set. For grinding, the author used paper at 80, and then at 120.

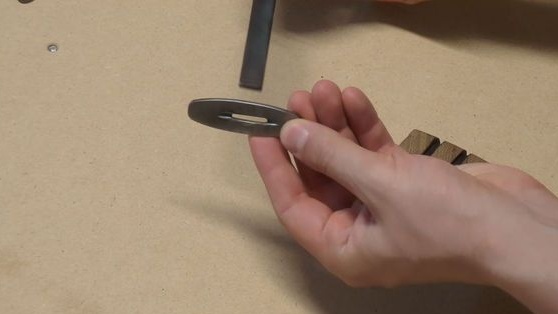

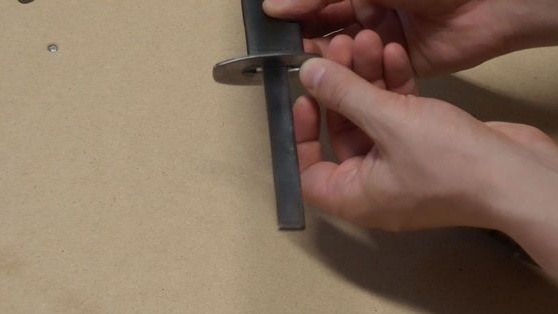

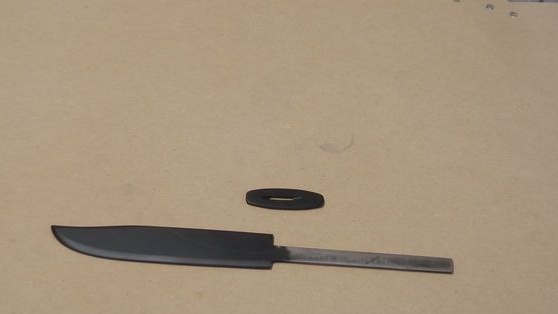

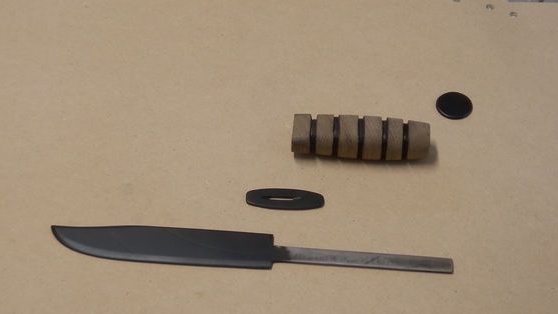

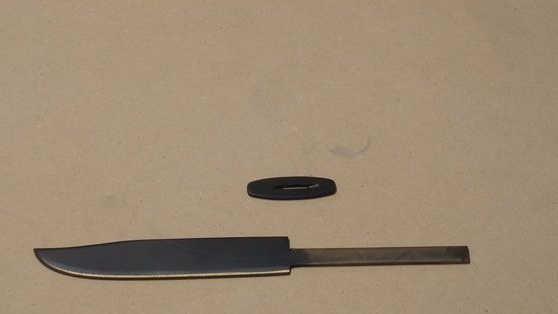

Step Four Knife stop

The author decided to make a kind of crosshair on the knife, as they used to do with swords. To do this, you need to cut off another piece from the disk and set the desired shape for it. Well, then this piece of steel is fastened with screws to the wood and a slot is made in it so that the handle of the blade can go there.

Step Five Pen making

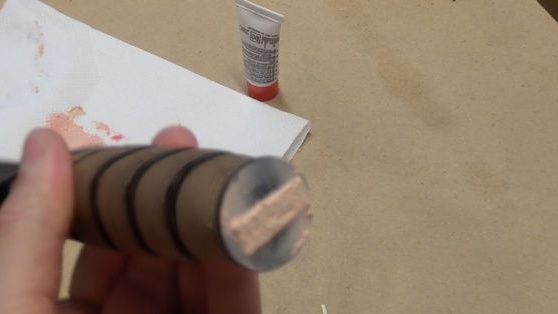

The author made a pen from walnut. After sawing off the desired piece, the handle is polished to the desired profile. Further, so that she lay firmly in her hand, the author made 3 mm slits in it. The slots can be painted over with a black felt-tip pen to highlight the pen, and then it is ground again.

In conclusion, a hole must be drilled in the handle so that a narrow part of the blade can enter it. You can drill several holes and then drill them with a file.

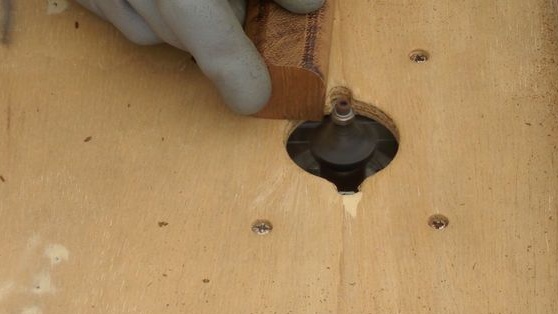

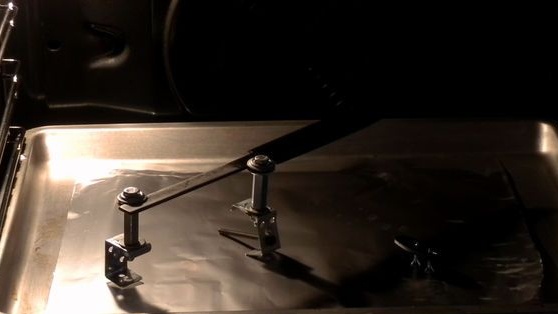

Step Six Quenching

For tempering, the author needed a can of canned food (suitable for paints, etc.). A gap is made in the lid into which the blade is inserted. Now the can is put on gas and due to the fact that it is closed, a high temperature is formed in it. After warming up the knife, the author dips it in oil.

The final stage of hardening was the placement of the blade in the plate for an hour with a temperature of 205 degrees Celsius. Before that, he is also sharpened.

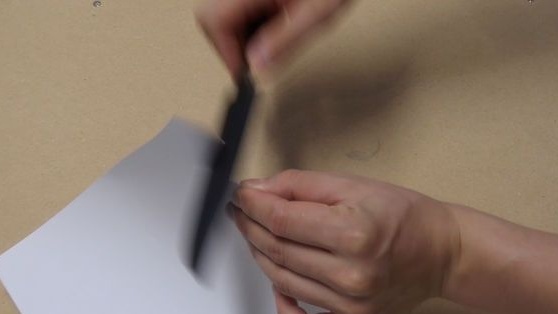

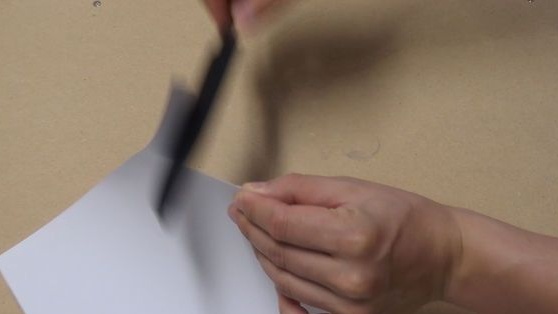

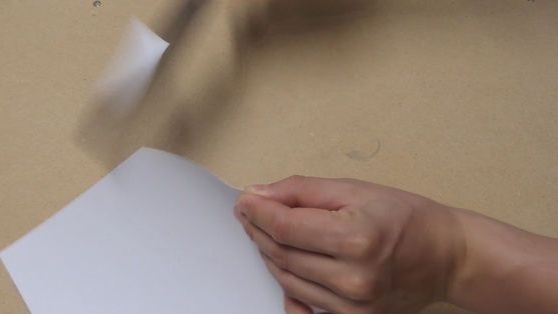

Seventh step. Fitting

At this point, the author checks to see if all the details fit together.

Step Eight. Pen detail

For the bottom of the knife, the author also cut out the part and set the desired shape for it.

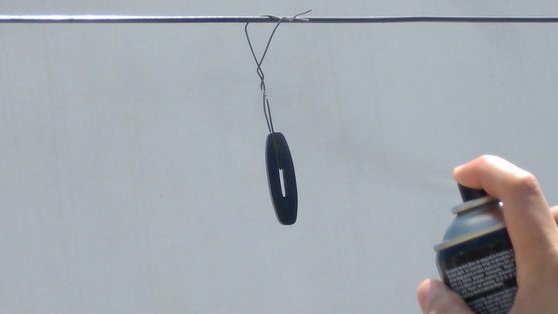

Step Nine. Painting

The author paints all the metal parts of the knife in matt black. Then the parts again bake in the oven for one hour at a temperature of 205 degrees Celsius so that the paint adheres securely.

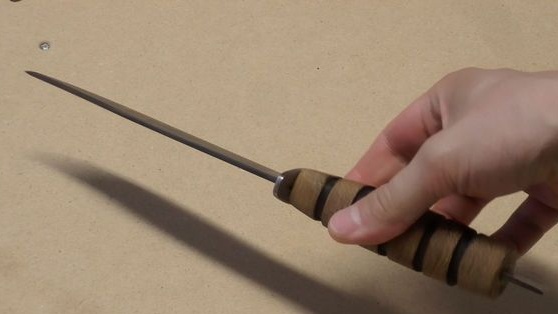

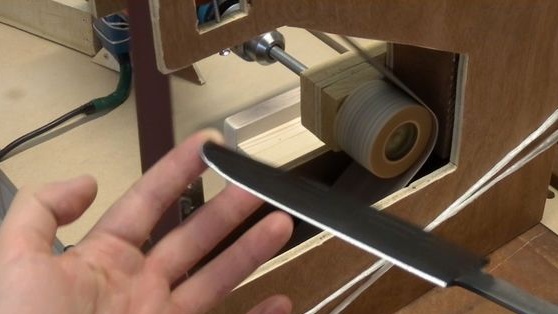

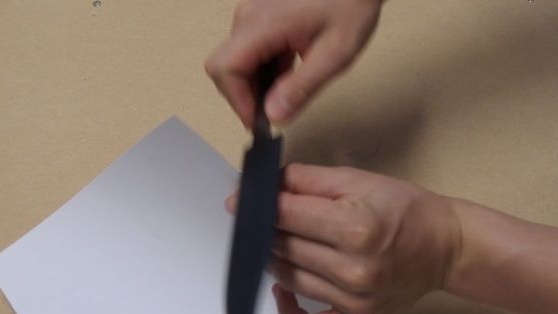

Step Ten Final sharpening

The blade is sharpened to the state of the blade; it should cut paper without any problems. Sandpaper was used on 220 and 400 here.

Step 11. And back to the oven

Once again, the author puts the blade in the oven for an hour at a temperature of 205oC.

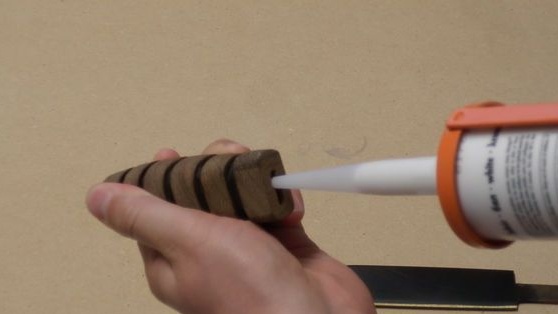

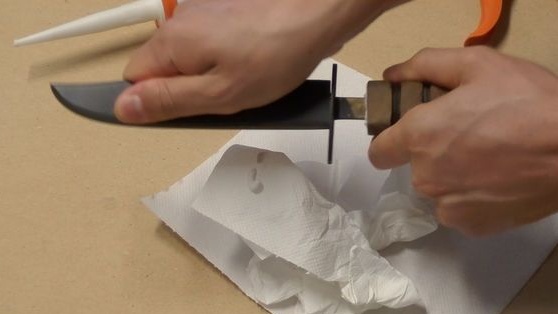

Step 12. Assembling the knife

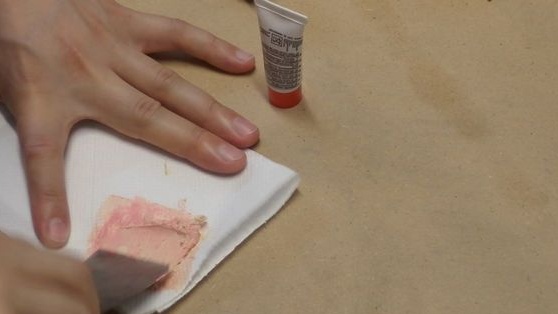

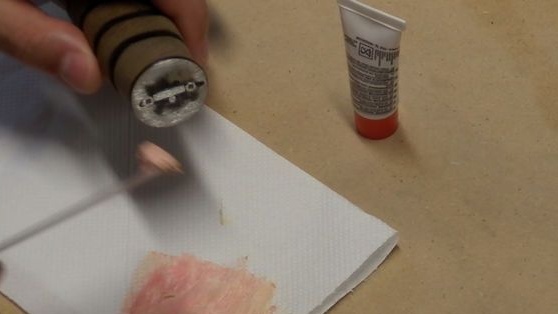

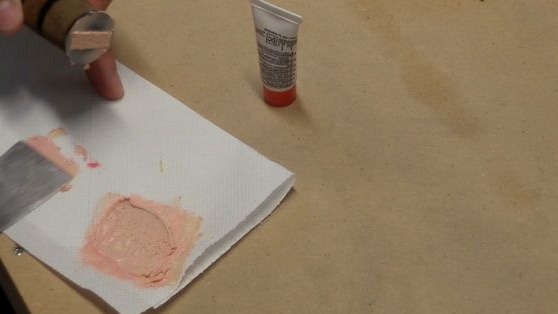

To assemble the knife you need good glue, an epoxy is suitable. Also, the author used polyester putty in the lower part to level everything together.

Step 13. Finishing Grinding

Now the handle is well sanded to perfect smoothness.

To store a knife, you need to grease its blade with oil, and the handle can also be soaked with oil or other special impregnations.