Once, a very long time ago (about 25 years ago) spring ties were made.

But time goes by, car repair has become my main profession and this tool has ceased to suit me. Having looked at the resources selling the instrument, I liked the stand.

But given the crisis, I did not like the price tag. Therefore, I decided to make something similar myself.

For manufacturing, you need a little scrap metal:

1) about two meters of a 40x60mm heterosexual corner (or a professional pipe with a wall thickness of at least 3 mm)

2) 2 bearings 201 (202)

3) 2 links of the traction conveyor chain (12-16mm rod

4) hardware (bolts, nuts, washers M10 and M12)

5) half a meter of professional pipe 15x15 and 20x20mm, 200mm professional pipe 40x60mm

6) 0.5 meter angle 50x50mm

7) five detachable, one stripping discs for angle grinder

8) a five millimeter steel tire or sheet metal of the same thickness

9) pipe with an inner diameter of 12mm

10) 1kg of three welding electrodes

11) the "classic" "Zhigulevsky" jack. You can use "Volgovsky" it is designed for more weight

12) welding machine

13) angle grinder (grinder)

14) drill (drilling machine)

15) some free time

Hook chain

Zhigulevsky jack cut off the supporting heel

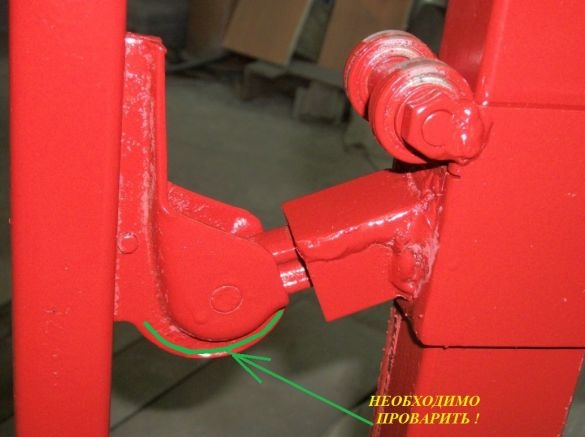

Turned the lever and welded the heel. It is advisable to boil the base of the lever (3 points of contact welding are not reliable!)

For rack fixtures corners 40x60mm 800mm long welded into a rectangle

I drilled 6 through holes f12mm, in increments of 50mm (indent from the edge of 25mm) on a short shelf.

The base of the chain grips and the carriage (both 90 mm high) are welded on the finished rack with a sheet of tin or wrapping the rack with sandpaper (as in photo 8) to ensure free movement along the rack (but with a minimum clearance)

For parallelism of the strips (L-130mm width 50mm) the base used a conductor of four M12 bolts (holes in the strips 40 and 100mm from the edge)

Guides of grippers from pipes 15x15 and 20x20mm (pipe in a pipe for rigidity) 150 mm long. The hole in the base in the center of the narrow side f12mm.

The manufacturing process is clear from the photos.

In a movable carriage, two samples of 20 mm deep are needed for bearings.The bearings are bolted through the spacer sleeve. I welded bolts and nuts to the carriage, you can make eyes and fasten to them.

On one side of the carriage (narrow side), a stop was welded for the jack lever (welded from a 32x32mm corner).

With opposite shock absorber clamp (L-80). Made of pipe trimming 40x60mm and corner with shelves 50mm. M10 tie rods on awnings.

The reciprocal part of a clip is welded from corners with regiments 20 and 32 mm

In the process of manufacturing this device constantly trying on

And tests

Ready stand

How it works is shown in the video.

For the manufacture of this stand was spent: on time - three days, on money - a little more than a thousand rubles (ferrous metal - 340r, hardware - 420r, 5 cutting wheels Ф 125mm (100r), 1kg of electrodes (200r), electricity. But working with it went much faster! It takes no more than 6 minutes to disassemble-assemble the rack.