Hello everybody! I want to share with you a simple but, in my opinion, useful homemade. It all started with the fact that when working with a hacksaw for metal, a completely new blade broke, and throwing out, though a broken, but a new metal file, like the hand does not rise. This was the reason for reflection and the search for ideas on the Internet. Now we can’t remember exactly where the self-made scraper for cleaning glass-ceramic plates was described, consisting of a small window hinge, a razor blade and a pair of small bolts with nuts that clamped the blade between the halves of the window canopy. As a result of minimal refinement, a hand tool was obtained, with which you can use broken metal sheets for cutting small parts, as well as for clamping and using blades from a stationery knife, razor blades, etc.

Tools and materials:

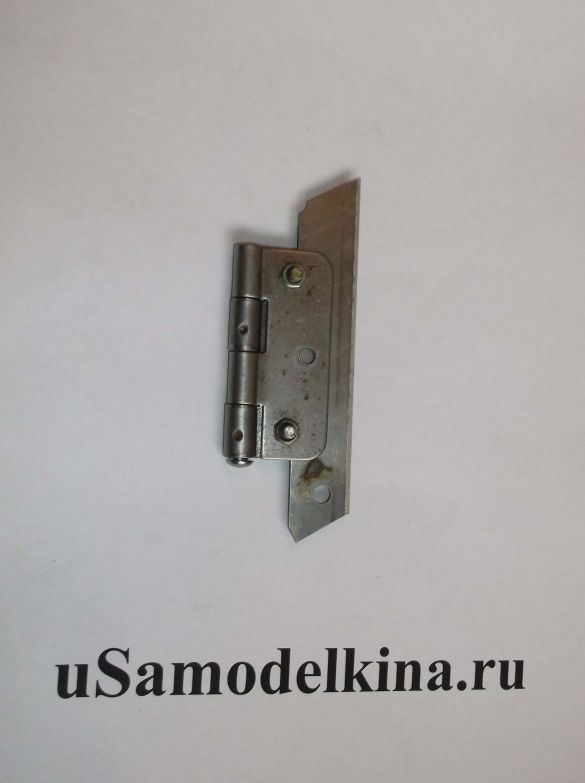

Small window loop

Piece of hairpin,

2 bolts and 2 nuts,

The handle is finished or homemade,

Drill,

Screwdriver

A file or emery may come in handy.

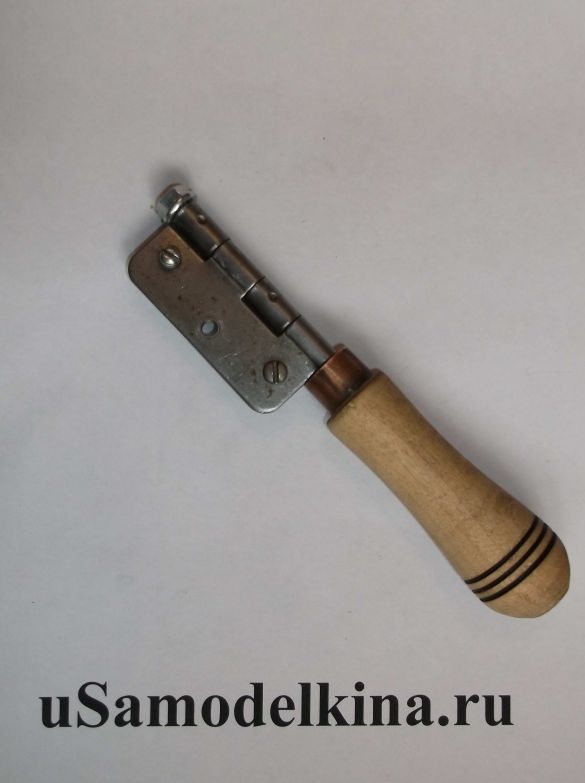

As you can see, this homemade product will require a minimum of parts and tools. For those who are interested in this idea - we continue. We take a universal window loop of a suitable size, in this case a loop of 60 mm was used. Insert pre-prepared small bolts into the outer holes and tighten with nuts.

At this stage, if you insert and squeeze the blade between the “jaws”, you will get a simple scraper for a glass-ceramic electric stove, which I mentioned earlier.

Instead of a razor blade, you can pinch the canvas from a clerical knife. It was a slight departure from the topic - we continue.

From the loop we remove the connecting cotter pin, which is replaced with a threaded rod of a suitable diameter and length.

Instead of a hairpin, you can use a long wood screw - this will only simplify the assembly of this fixtures. I have a hairpin in diameter slightly larger than the required size and I had to sharpen the thread a bit to put it all together.

We take a ready-made handle or, in the presence of a lathe, we grind a homemade one in size. We drill a hole in the end of the handle with a slightly smaller diameter than the diameter of the stud.

We screw the hairpin together with the canopy into the handle. Since the diameter drilled in the handle is smaller and the thread on the stud is larger, a reliable connection is obtained that does not require additional fixation.

That's all, you can fix our fragment of the canvas and use it for small jobs. But I want to note that the functionality of this device is not limited to this.

We clamp the chip from the blade of the clerical knife and get a convenient cutter.

You can fix the file that does not have a handle and it will become much more convenient to work with it. In my opinion, there are many more applications for this device.