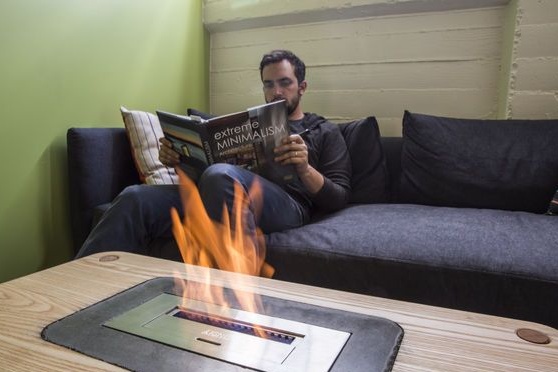

The original coffee table with a built-in ethanol burner was invented and made by the Master.

Tools and materials:

-

-A circular saw;

-Drilling machine;

-Band-saw;

-Grinder;

- Clamps;

-Bucket;

-Mixer;

-Acrylic cement;

-Polyurethane;

-Acrylic;

-Boards;

- dowels;

- Putty;

-Glue;

-Linseed oil;

-

-

-

-

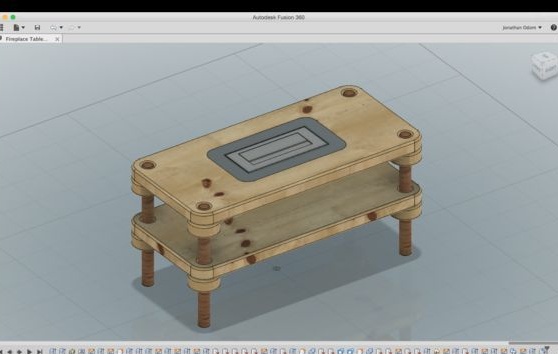

Step One: Project

First, the master developed a table design. The table consists of 2 tiers. A burner is integrated in the upper tier. The legs are made of thick dowels. The legs are threaded. Also, the thread is cut into the countertop.

Step Two: Wooden Parts

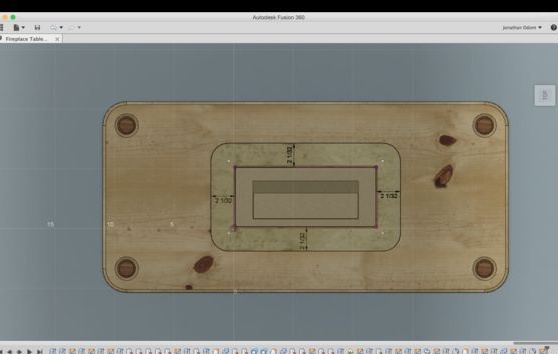

The craftsman made the countertops from the board. I glued two boards and cut them to the right size. He made holes in the corners of the countertops. Cut the thread. In the center of one of the countertops cut out a compartment for installing the burner. I ground it and covered it with linseed oil. I also cut round nuts from the board. I cut the thread. I cut the thread on the legs.

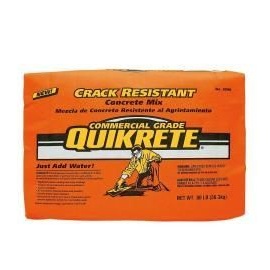

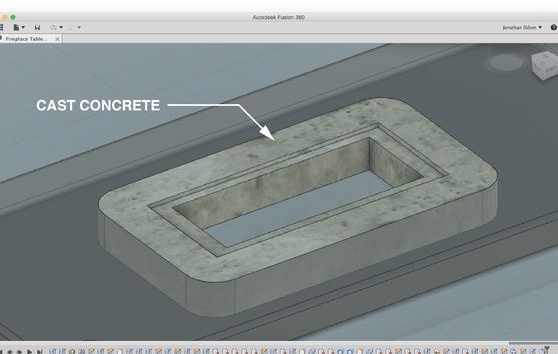

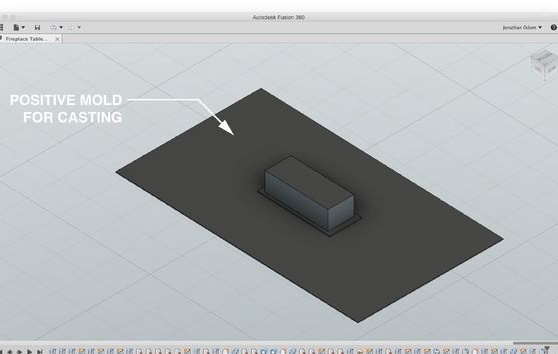

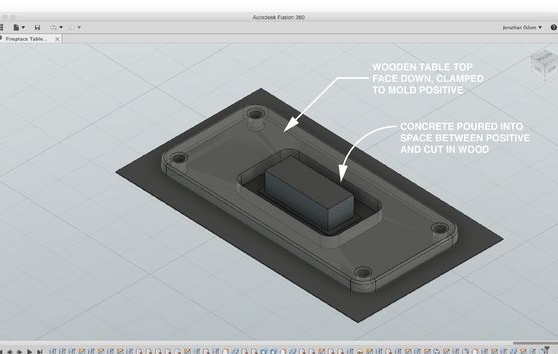

Step Two: Concrete

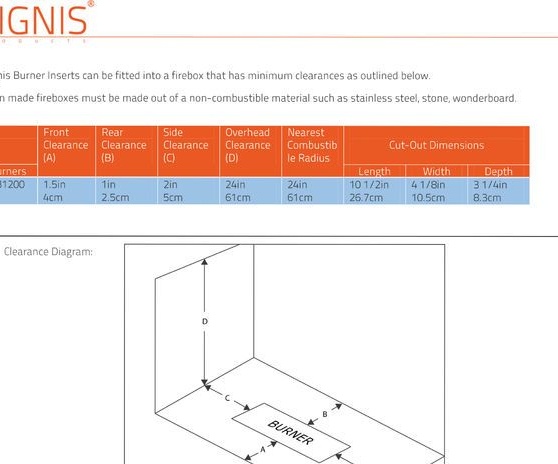

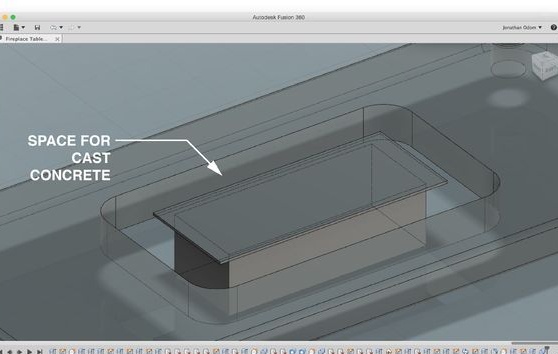

For safety reasons, the burner must not come into contact with combustible materials. Therefore, the master, between the burner and the wooden countertop, makes a concrete insert. The first experience with reinforcing concrete with a mesh failed. In the future, the master instead of the mesh used special additives in concrete.

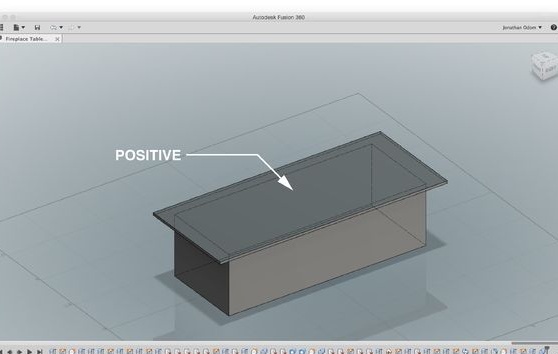

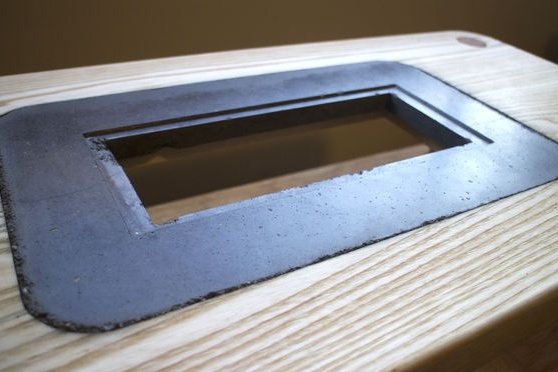

The master made the shape of the concrete part from acrylic. The wooden parts of the countertop that come in contact with concrete are treated with polyurethane.

Inside the countertops around the perimeter installed dowels for strength. Knead and poured concrete. After hardening, during the day, I added a wooden grate from the bottom of the concrete insert. Coated with concrete. Set the burner.

Step Three: Build

Now you can start assembling. Screws the legs into the countertops. Tightens the nuts.

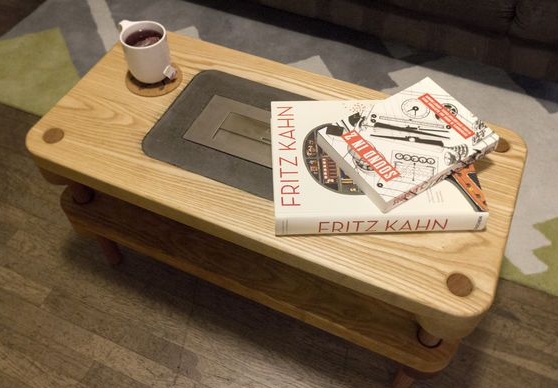

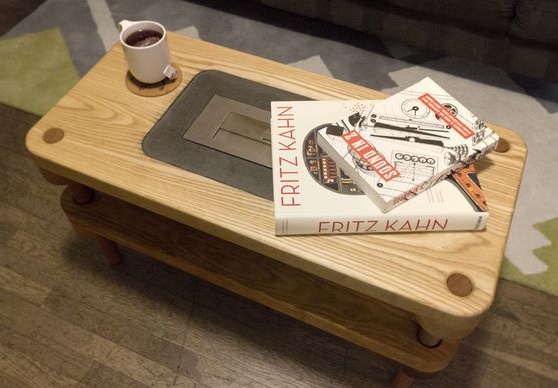

A coffee table with a hearth is ready. If necessary, the burner closes and the entire area of the table is used.