The fan made by the Master is an analog of the Dyson fan. Such a fan is safe for children, since there are no moving parts on the outside. The most important difference from the Dyson fan is the price. A branded Dysonovsky fanless fan, in a Russian online store, costs from 9,000 to 32,000 tr The fan cost about 600 rubles to the master. In its manufacture, the master used the most common

Tools and materials:

-Three PVC pipes of different diameters;

-

;

-Roulette;

-Pencil;

-Sandpaper;

-Plastic food container;

-Knife;

-Insulation tape;

-Drill;

-Crown on wood;

-Glue;

-Fiberglass;

-;

- Spray can with paint;

-LED Strip Light;

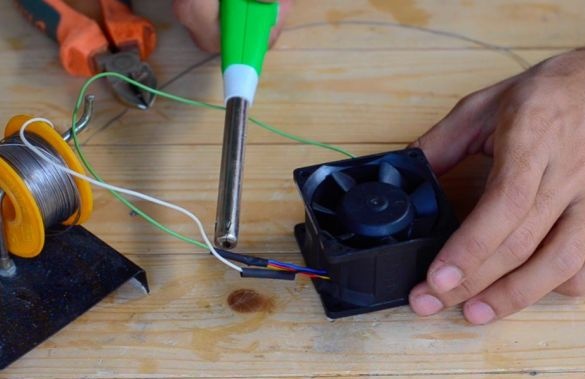

-Soldering iron;

-;

Heat Shrink;

-Wire;

-Screwdriver;

-Fasteners;

-Scissors;

-Grid;

- Thermogun;

-Plug;

-Pliers;

-Tumbler;

-Burner;

-Drill;

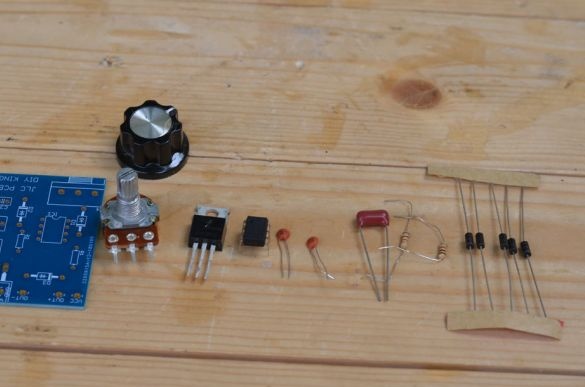

-Printed circuit board;

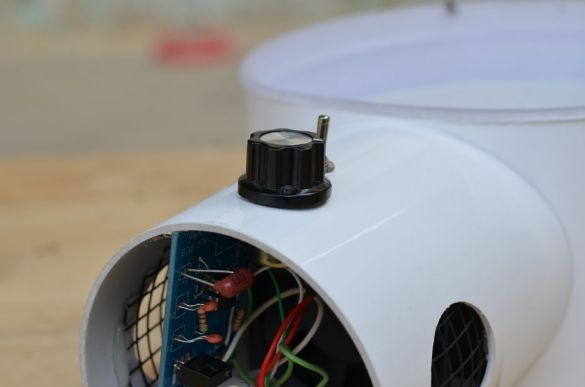

-Potentiometer;

Schottky Diode;

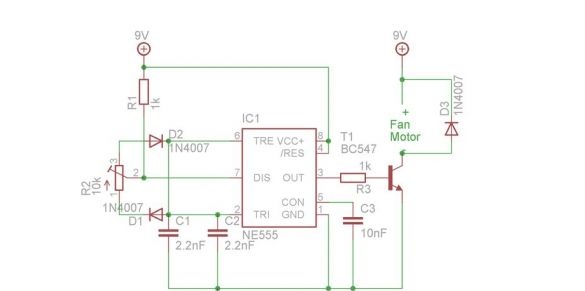

-Integrated Circuit NE555;

-Capacitors;

-Resistors;

-Diodes;

-Rubber legs;

-Power Supply;

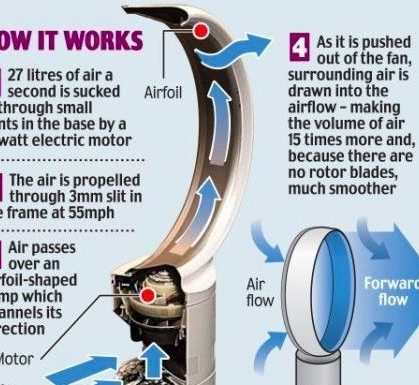

Step one: the principle of operation of the fan

Of course, the fan has blades, but they are hidden in the case. When the fan is operating, the air flow rises along the channel of the housing and leaves its upper part.

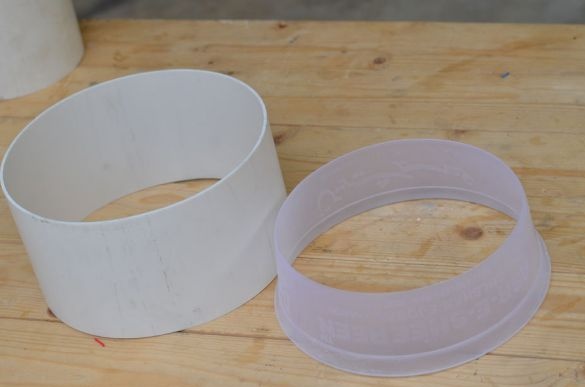

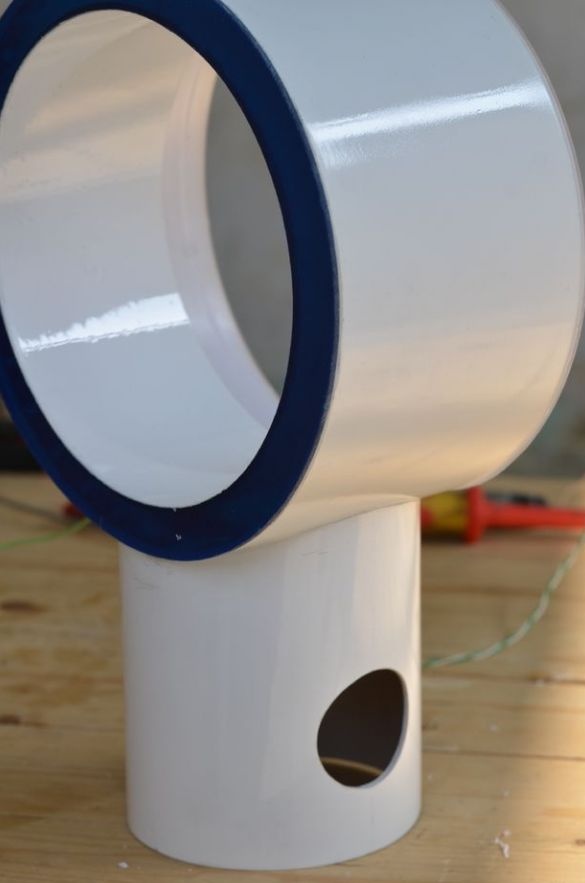

Step Two: Outer Ring

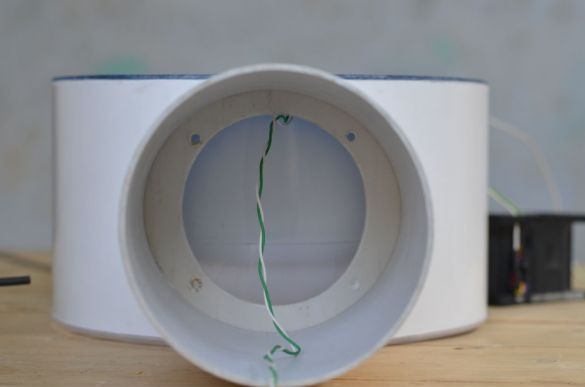

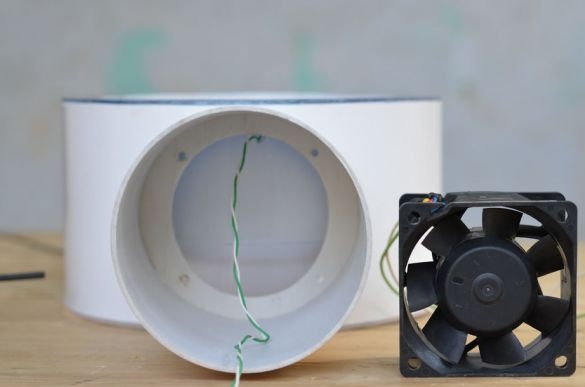

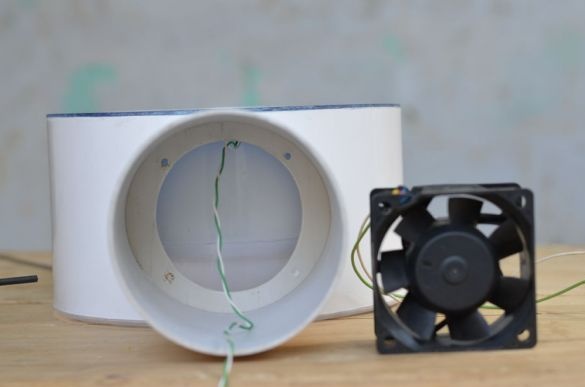

From a PVC pipe, 6 inches (15.24 cm) in diameter, cuts out a ring.

A ring with a side cuts off the container and installs into the pipe.

Step Three: Inner Ring

Cuts a ring from a 5 inch (12.7 cm) pipe.

Step Four: Stand

From a 3.5 inch (8.89 cm) pipe cuts a rack. Rack height 13 cm.

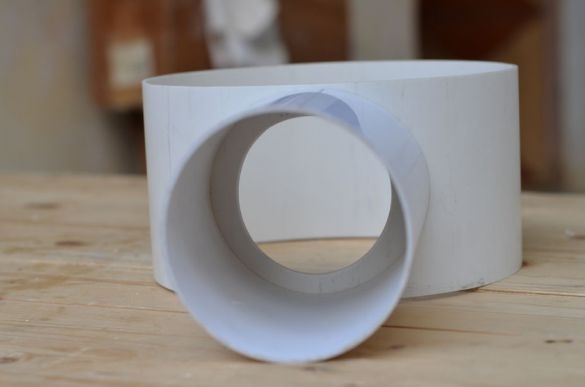

Step Five: Housing Assembly

Begins body assembly.

Trim a semicircle on one edge of the rack. The upper ring will rest on it. Fits the cut with sandpaper.

In the upper ring cuts a hole. Glues the ring to the stand.

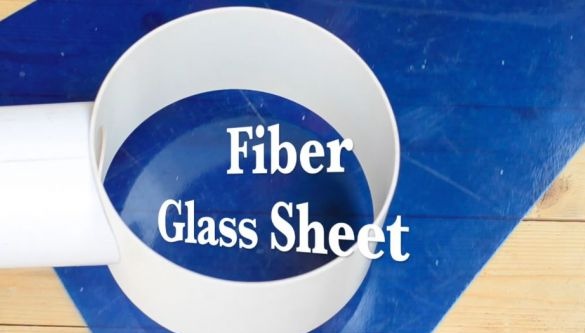

From fiberglass cuts a ring.

Glues it to the inner ring.

Step Six: Painting Parts

Seals a fiberglass ring with electrical tape.

Paints parts of the body.

After drying, the paint removes electrical tape.

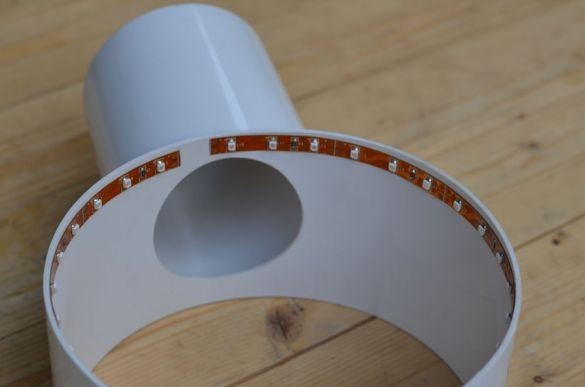

Seventh step: LED strip

Glue LED tape to the inner edge of the ring.

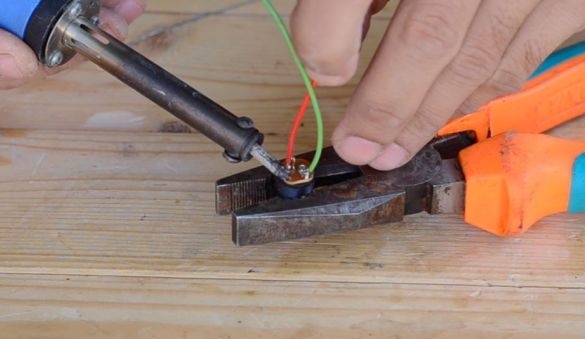

Solders to the contacts of the wire.

Sets the inner ring.

Checks the operation of the LEDs.

LEDs work, glues the ring into place. Glues the ring from the container.

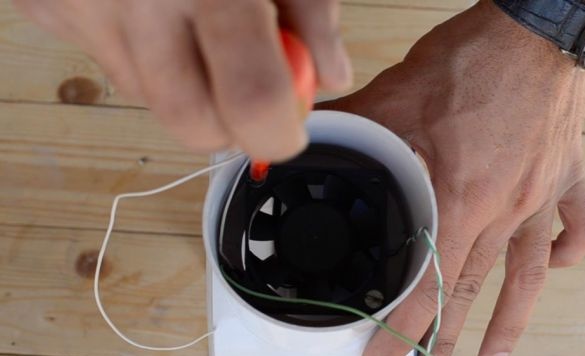

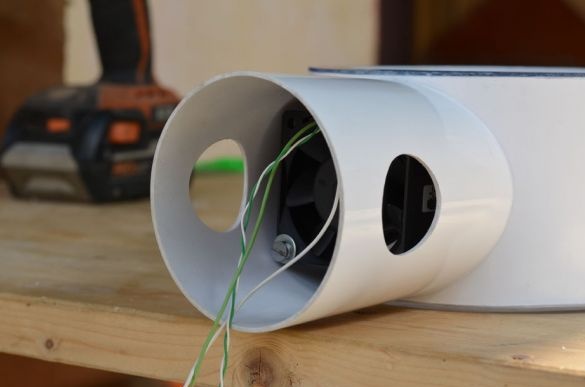

Step Eight: Fan

Solders to the wires fan contacts. Installs the fan in a rack. Tightens.

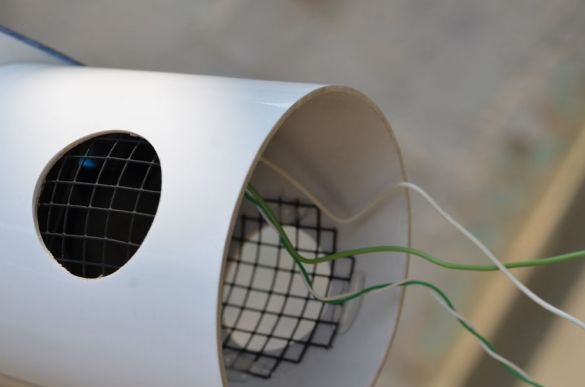

Step Nine: Air Intake

The rack cuts two holes.

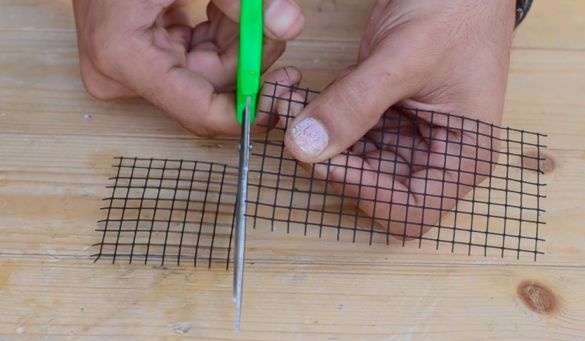

Cuts the grid.

Glues the mesh.

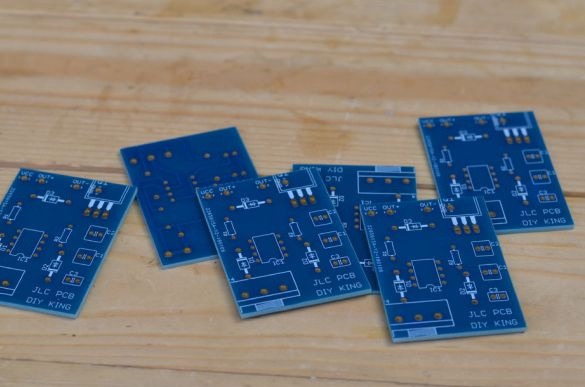

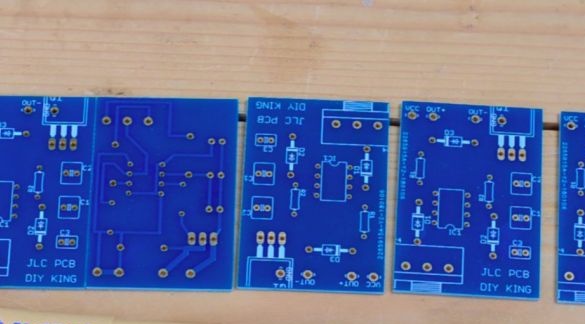

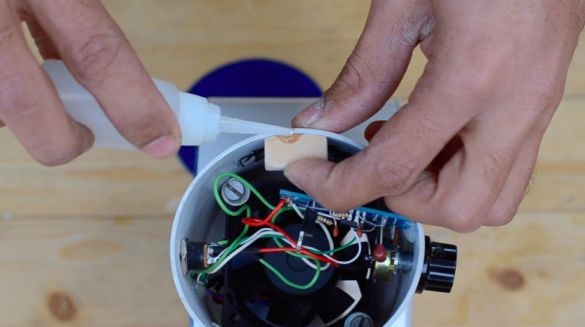

Step Ten: Speed Control Unit

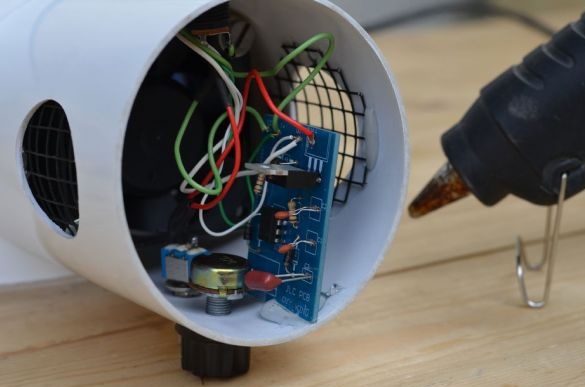

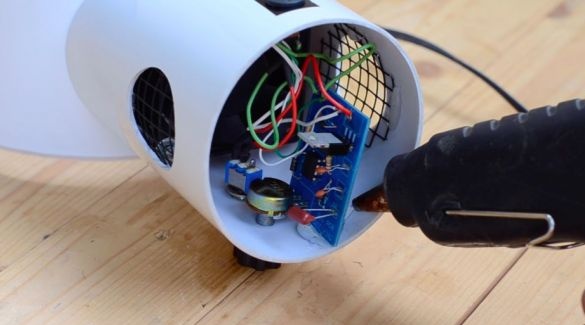

The master ordered the board for the control unit on a specialized site. The price of ten boards is $ 2 with delivery.

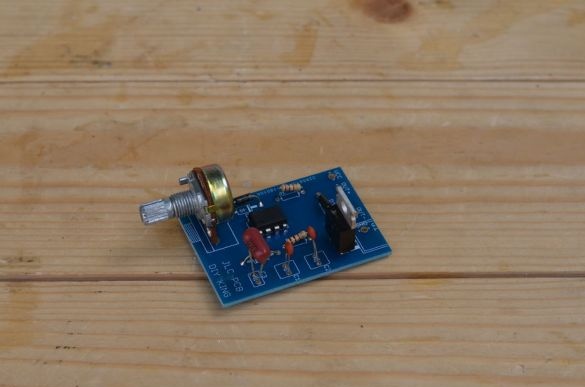

According to the scheme mounts the control unit.

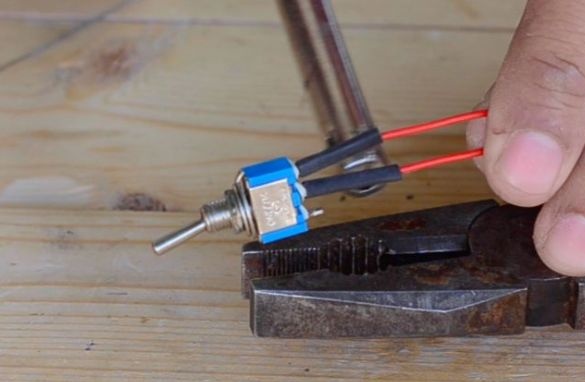

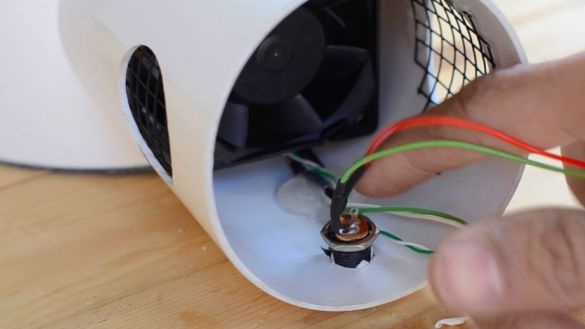

Installs a socket and a toggle switch in the housing.

Installs the board.

Step eleven: bottom cover

I glued two wooden bars.

I cut a cover from fiberglass. Screwed the lid. Glued rubber feet.

The fanless fan is ready. It remains to connect the power supply and check its performance.

The whole process of manufacturing a fan can be seen in the video.