If you have a compressor in your workshop, then you definitely need to make this tool, which you will certainly need and will help you out when you perform certain tasks. This tool is a sandblast made do it yourself, under the pressure of the compressor, it releases a continuous stream of sand. It can be useful for sanding certain parts or for removing old paint from surfaces.

To make such a tool you will need:

- A liter plastic bottle with a cap.

- Gun from compressor

- Drill

- Screwdriver and screwdriver

How to make a sandblast

So, we take the gun from the compressor

Next, twist the nozzle nozzle from it. The gun must have a replaceable nozzle, otherwise it will not work to make such a tool.

Then you need to hold the nozzle in a vise and use a square file to cut to the middle of the tube. Propyl should be about a centimeter wide and depth to the middle of the tube.

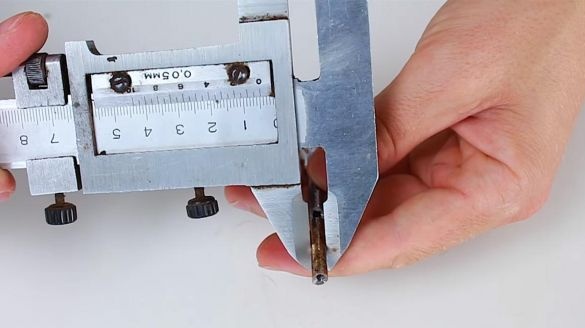

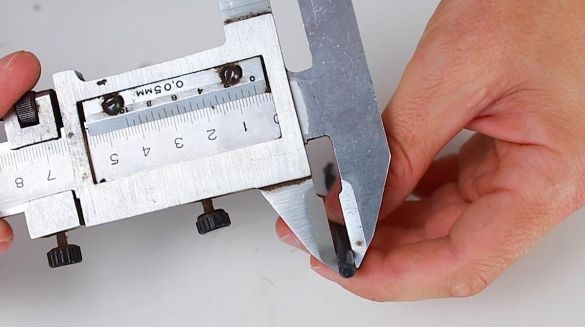

Next, using a caliper, measure the diameter of the tube.

Then we select a drill that should correspond to the diameter of the tube. For this, we also use a caliper.

Now you need to fix the drill in the screwdriver and make a hole in the neck of the bottle as shown in the photo below. It is advisable to make a hole evenly, being careful not to drill the edges. First we remove the plastic ring on the neck of the bottle, it is in this place that you need to make a hole!

After the release is done, we take ordinary sand, you can sifted, you can not and pour into a bottle.

Now it remains the case for small. We twist the cap and through the hole in the bottle we pass the nozzle screwed onto the gun, the slot in it should be inside the bottle.

Now it remains only to connect the gun to the compressor and use. Depending on the application and the surface to be treated, it is possible to sift the sand a little finer or vice versa to leave it with large particles.

This tool very well exfoliates old paint from any surface, so now you can easily prepare it for painting. Also, you can polish different parts, beat rust and so on. A stream of sand easily breaks holes in a can. That's all, thanks for watching!

Video homemade: