Hello everyone, in this instruction I will tell you how to make the legendary Butterfly knife. We often see such a knife in various films, it’s a tool beloved by all hooligans. And it’s not without reason that this knife is very convenient, has a chic appearance and is durable due to its simple design.

In making the knife, the author used quite serious equipment, but this does not mean at all that it cannot be made with common tools, the only question is how much time you will make it. The most difficult is the manufacture of grooves in the handles into which the blade will go. In principle, the pens are made of aluminum, and this metal is quite easy to process.

There is also a lot of work to be done on grinding, it would be useful to have a belt grinder here. However, its absence is also not an obstacle, as many masters prove, making wonderful knives with hand tools.

Materials and tools used by the author:

Material List:

- (if you need a good knife);

- aluminum bar (for the manufacture of pens);

- screws;

- washers;

- spring.

Tool List:

- grinder;

- vise;

- ;

- ;

- clamps;

- hammer;

- marker and more.

The process of making a knife:

Step one. We start with the blade

We start with the manufacture of the blade, here you will need high-carbon steel, only this type of steel can be hardened. Today you can easily buy a blank for making a knife. Also, similar steel can be found in some saw blades and other tools. Typically, good steel has spring characteristics.

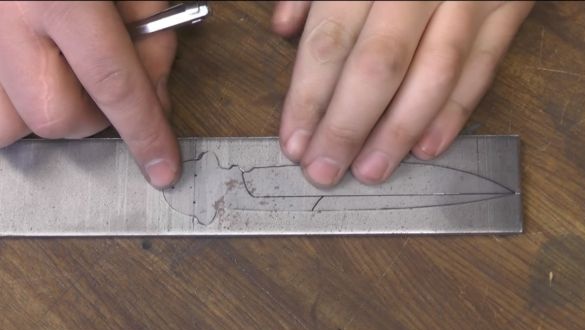

We apply a template, draw a marker and drill holes. The blade is made according to the standard scheme, the peculiarity is that the blade has a special “bracket” to which the handles are pivotally attached.

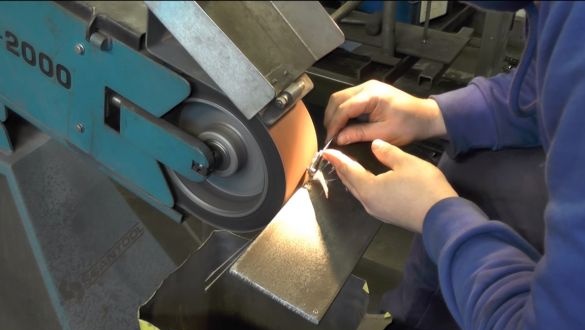

The author cuts the main profile with the help of a grinder, holding the workpiece in a vice. Well, then comes finer processing, for this a belt sander is used.

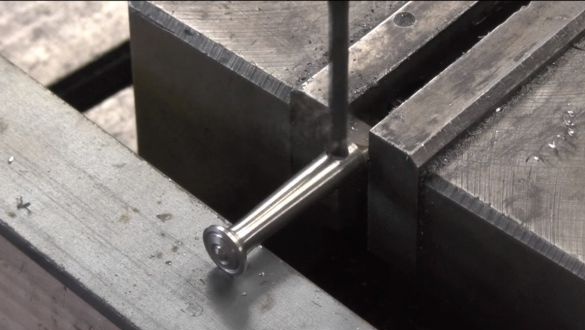

In the end, you will need to form the bevels on the blade, as well as install the pin. It is most convenient to make bevels on a belt sander by installing a blade on a bar. As for the pin, it must be pressed into the blade and sanded to the desired size.

If you want to get a really high-quality blade, you definitely have to temper it. To do this, we warm the blade to a yellowish glow and cool in oil. To accurately determine the hardening temperature, bring a magnet to the red-hot metal, it should not react to steel.

In an extreme case, water is also suitable for cooling, but in it the blade may crack or lead due to too intense cooling.

After hardening, warm the blade in a household oven at a temperature of 250 degrees Celsius for an hour or two, and then let it cool gradually. Now your blade will no longer be fragile, it will spring under heavy loads.

At the end of work with the blade, sand it on fine sandpaper dipped in water. Well, then the blade can be polished on the machine to a mirror shine.

Step Two Getting to the handle

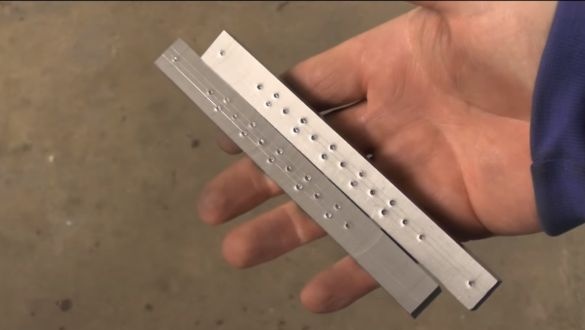

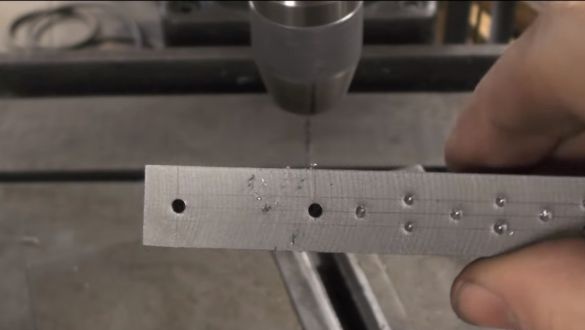

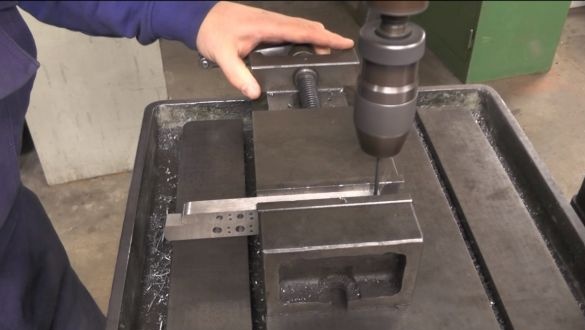

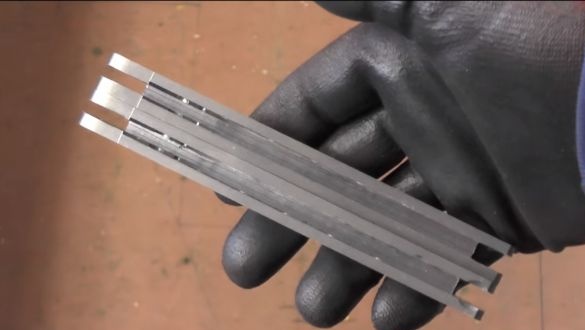

To make a pen you will need two aluminum bars. First of all, mark the places for the holes and drill. Most of them are needed for decorative purposes. The author used a diverse number of machines for making pens, but everything can be done manually.

The most difficult will be to cut the grooves under the blade, the author for this needed a machine with a special "thick" disk. If you try very hard, all this can be done with the help of a grinder and a grinding disc.

At the end, the handle is ground on a belt sander to the desired profile. Final processing is done manually using sandpaper.

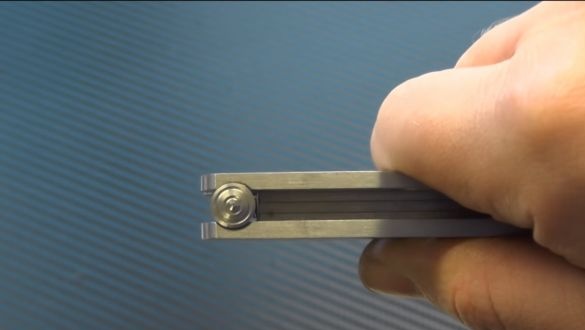

Step Three Handle lock

The latch can be machined on a lathe or just in the chuck of a conventional drill. As a material, aluminum or steel is suitable. We form a profile as in the photo and drill a hole for fastening.

Step Four Putting a knife!

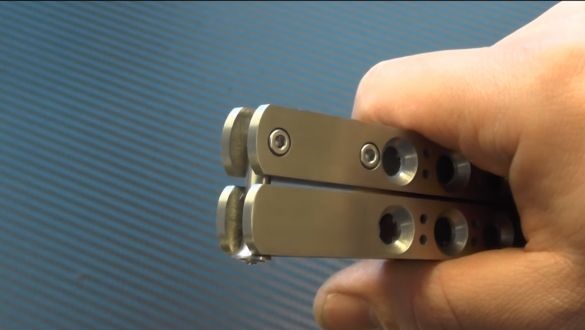

To assemble the knife, you will need screws, they are wrapped in a thread that is cut into handles. The screws must be shortened to the desired length. After tightening the screws, both halves should rotate easily relative to the blade. When the knife is open, the handles fix the blade to the axis that is installed in it.

All that remains for you to install is the handle lock. It is also fastened with a screw and spring loaded, this allows you to quickly bring the knife in readiness. That's all, on this the manufacture of a knife can be considered complete. At the end, grind it to the state of the blade, if necessary. According to many masters, the easiest way to sharpen a knife is with fine sandpaper, periodically wetting it in water. Japanese water stone and others are also well suited for sharpening fixtures.

That's all, good luck and take care! Use this creation only for good purposes.