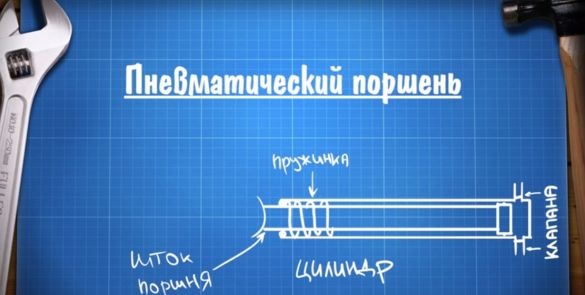

At the heart of this gun is pneumatic piston catapult.

One of the most important components is this is such a reservoir for compressed air (you can see how to make it on the channel of the author).

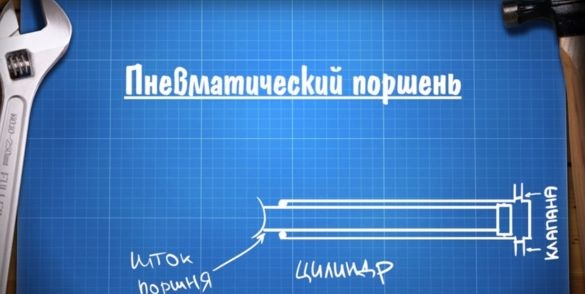

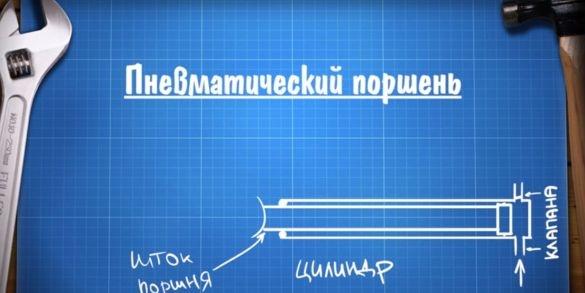

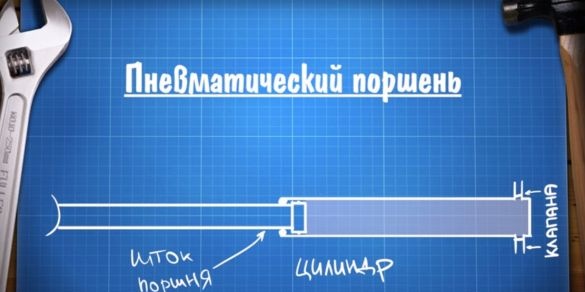

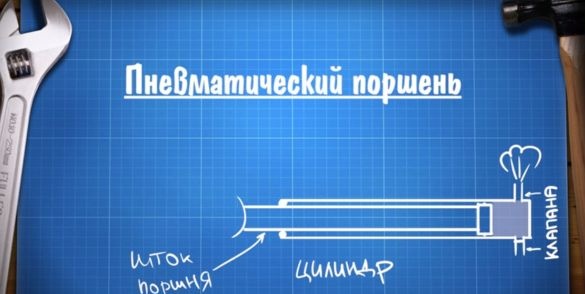

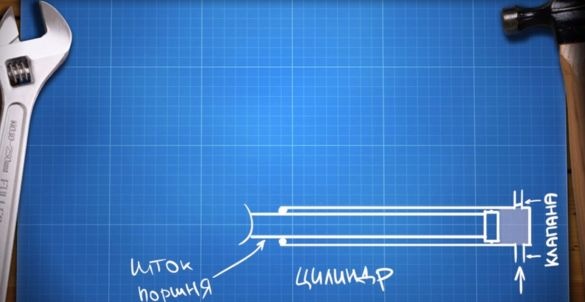

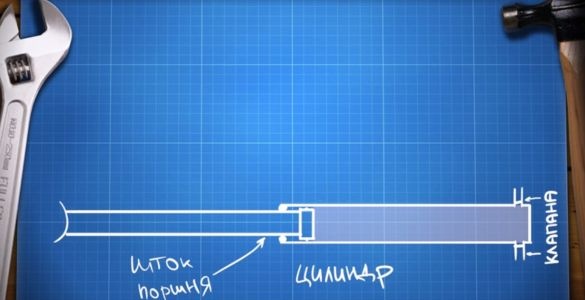

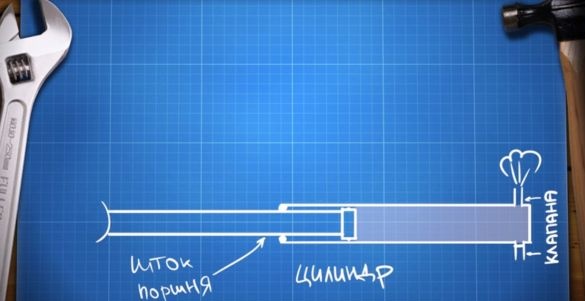

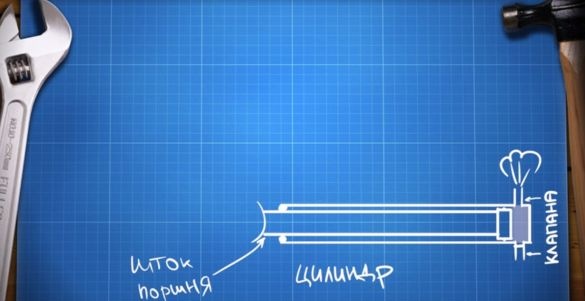

This gun will work on the principle of a pneumatic piston. There is a piston with a cylinder.

Through the inlet valve, compressed air is supplied under the piston.

The piston will begin to move and thus be able to accelerate things to decent speeds.

To relieve pressure under the piston, open the exhaust valve and spring or manually move the piston back.

But there is one dangerous point: this is when the piston at high speed must stop at the opposite edge of the cylinder. To mitigate this blow, we will use just such a spring, which you can buy in auto parts.

Let's get down to manufacturing!

We will use such a 20 mm aluminum tube as a cylinder.

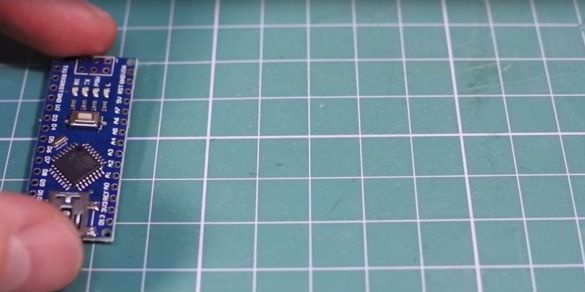

The valve will be electromagnetic, and we will control the closing and opening by arduino.

The air from the valve will enter the cylinder through such an adapter from 1/4 to the euro-connector.

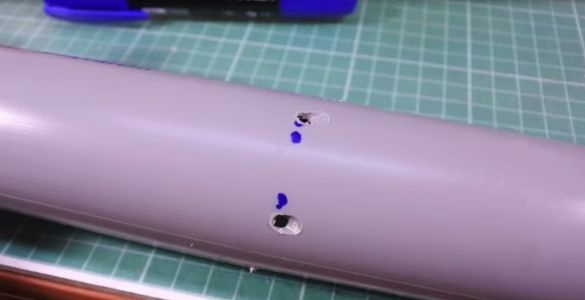

We note the place under the hole for the adapter, taking into account the fact that the front of the cylinder will be at the same level as the cylinder with compressed air.

Then we drill and drill a hole.

An exhaust valve will be located next to it. Included with it was such an adapter for a hose.

We drill a hole under it.

We shorten both fittings to the cylindrical part.

The piston cylinder itself will be closed by a cold welding plug.

And so that it definitely doesn’t vomit, we drill a hole for a pin from thick steel wire.

We put a bounding wall of cardboard, then a pin and cover the hole with cold welding.

We put the output from the valve into the cylinder and weld it with the same cold welding.

Temporarily fix the cylinder with hot glue.

All cold welding can be covered with electrical tape

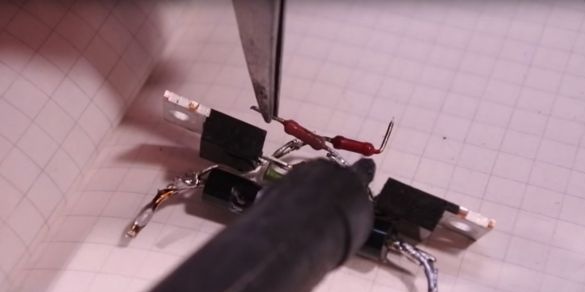

Carefully solder the valve control circuit with arduino

Download the scheme and sketch here:

By pressing the shutter button, the inlet valve opens and air enters the cylinder, after a few seconds the valve closes, and after a few seconds the exhaust valve opens and closes only when we release the shutter button. During this time, it will be possible to safely return the piston to its original position.

Such a thick-walled plastic tube will be the piston rod.

The piston will be made of cold welding.

Again, you need to make protrusions to hold it (this time from carnations).

We get a powdery pencil lead. This will be the piston cover.

We knead cold welding, form a cylinder on the surface of the rod and roll it along the powder lead.

Here is such an analogue of graphite lubricant. Using a piece of pipe with smooth walls, we form a piston.

Now you need to wait until it dries completely. By the way, the piston slightly increased on drying, and I had to grind it. As a result, it turned out to be partially mirrored and simply worked perfectly perfectly in the cylinder.

In fact, with a piston, you can not bother so much and use such rubber sanitary pads.

But in the cold, they create a lot of friction in the cylinder, and the cold welding piston works almost without it. For comparison: the load from the rubber piston is -150 grams, and from the cold-welding one it is almost zero. And this is with complete tightness!

We make the piston pusher from the bottom of the can with soda. For fastening to the rod we screw a self-tapping screw.

The rod itself will be a centimeter longer than the cylinder (you can even cut it off with scissors)

Rubber gaskets and such a spring will help to reduce the impact from the piston.

At the end of the cylinder you need to make an emphasis on which the spring will abut. We drill two holes into which a piece of steel wire will be inserted.

Fill the tip of the rod with hot glue and glue the pusher there.

First test. Works!

We will use such a 50 mm sewer pipe as a barrel and a body.

Saw off the end, then mark the length we need and saw off the excess.

Now mark the place where the balloon ends, and the width of the balloon itself.

We mark out the part that needs to be cut to cover the power cylinder with a pipe.

Now carefully file the piece, and then put it in its place.

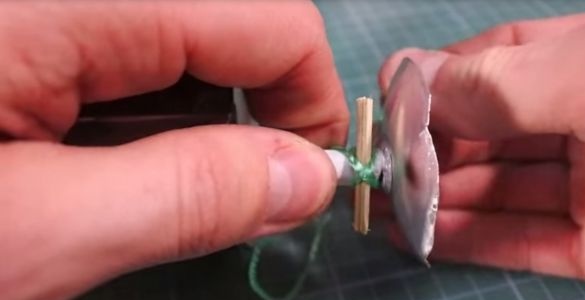

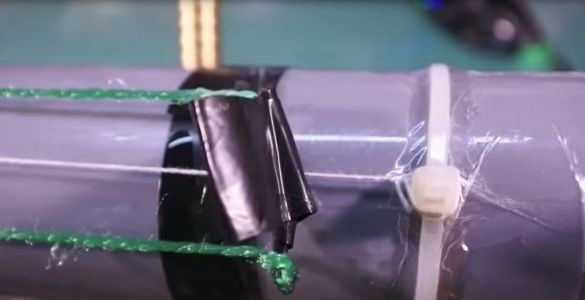

It remains to make a piston return system. Directly in front of the pusher we firmly tie a piece of bamboo skewer (for reliability we cover it with hot glue).

Directly above it we mark and drill several holes for rope rods.

Skip both ends of the rope and tie out to the skewer.

Now we put the barrel in place and fix the length of the ropes in the extended position of the piston.

Glue the barrel to the cylinder with hot glue.

Throughout electronics hide in a bag and wind it with electrical tape between the cylinder and the barrel.

We simply glue the button in the place where it is convenient for you to press it with your thumb.

For the valve return rope, you can make a holder from electrical tape.

In practice, it works like this: we shoot, the valve with the rope goes forward. The exhaust valve opens, air leaves the cylinder and now we can return the piston to its original position. Only then can the release button be released.

That's it! The catapult is ready! Now you can experience it!

Original video by the author: