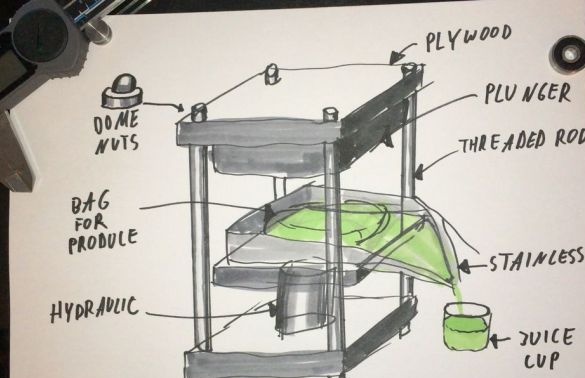

Juicers have one significant drawback, they do not fully squeeze the juice and quickly clog. The master decided to make a juicer built on a different spin principle. To do this, he needed the following

Tools and materials:

- Plywood 40 mm;

-4 ton hydraulic jack;

- Threaded rod 10 mm;

-Flange;

-Stainless steel sheet;

-Primer;

-Paint;

- Joiner's glue;

- Jigsaw;

-A circular saw;

- Band saw;

-Miter saw;

-Hacksaw;

- Cordless drill;

- Clamps;

-Grinder;

-Roulette;

-Pencil;

-Hammer;

-Pliers;

-Ushm;

-Screwdriver;

-Fasteners;

-Wooden dowels;

-Bearings;

-Plastic plate;

-Hooks;

-Springs;

-Metal tube;

Step One: Tray

From 1.5 mm stainless steel makes a tray 180 * 180 mm. The tray has a spout for draining juice.

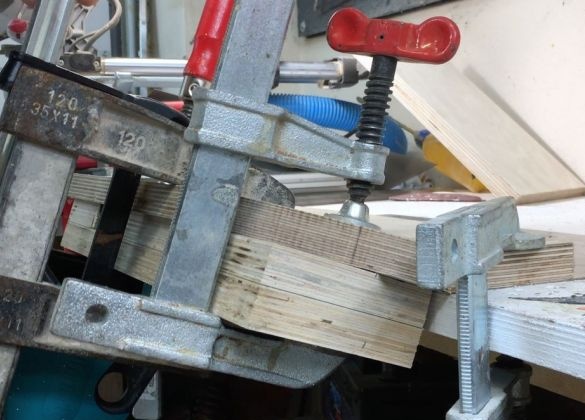

Step Two: Plywood Procurement

Plywood must be at least 40 mm. Cuts four workpieces: two 300 mm x 300 mm x about 40 mm (top and bottom), one 220 mm x 220 mm x 220 mm x 40 mm (tray holder) and three 160 mm x 160 mm x 40 mm (piston).

Step Three: Top and Bottom

Grinds the top and bottom. At the corners, drills holes for the studs.

Step Four: Studs

Cuts the studs to the desired length.

Step Five: Piston

Glues three blanks for the piston.

Step Six: Tray Holder

On three sides of the workpiece glues slats. A jack will press on the holder, so the master reinforces it, from below, with a metal plate with a flange.

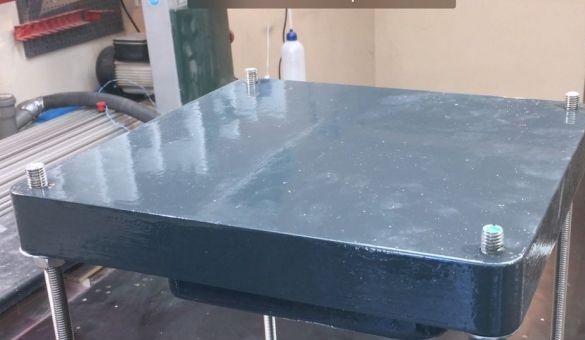

Seventh step: painting

Covers parts of the juicer first with a primer and then with paint.

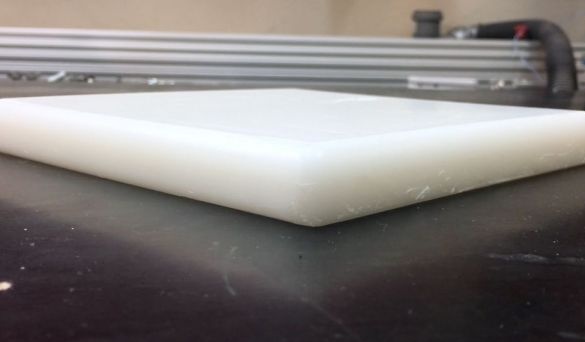

Step Eight: Plastics

The products must come in contact with the safest materials. Bottom is a stainless steel tray; on top, the master decided to install a food plastic lining. To align the lining, I screwed a screw into the plastic, and glued a magnet into the piston.

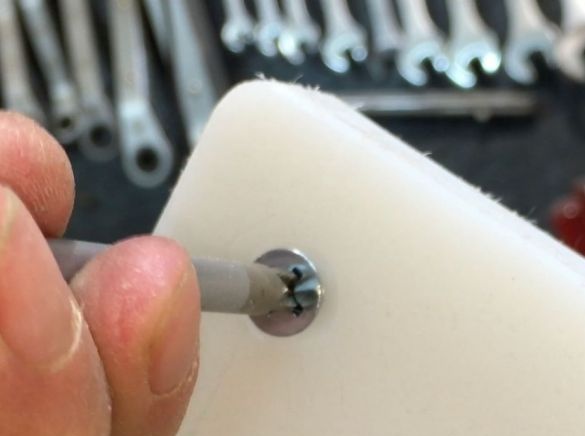

Step Nine: Pen

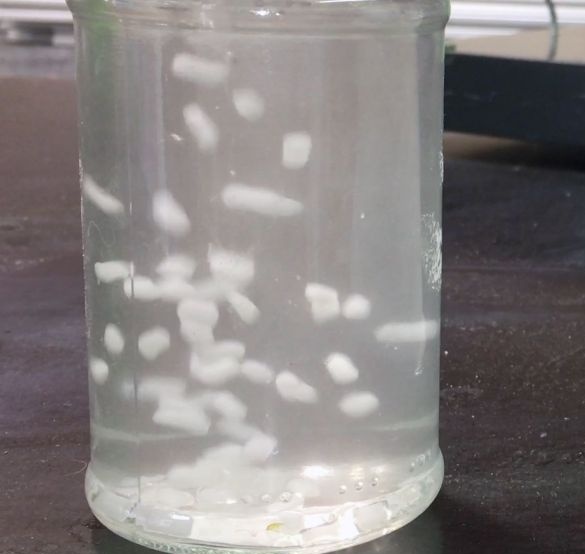

When the jack handle is pressed, the pump pumps fluid and the rod rises. To lower the rod to its original state, it is necessary to unscrew the screw of the pressure relief valve. Typically, these screws have a turnkey face. To facilitate the loosening of the screw, the master decided to make a handle made of water-soluble plastic on the screw.Plastic granules fall asleep in boiling water. After melting it pulls them out and makes a pen.

One more handle, makes and installs on the piston of a jack.

Step Ten: Build

Collects a juicer. Fastens the bottom and top to the studs. A flange is screwed to the tray support. Sets the jack. Tightens the springs.

The press is ready.

To squeeze juice from hard fruits, you must first cut them into slices. Then wrap in gauze. Put in the tray. And squeeze the press.

The whole process of assembling a press for squeezing fruits can be seen on the video.