Good day to all. In this article, we will consider how one master assembled a mini lathe on wood from improvised materials.

For the machine, the author took the 775 electric motor.

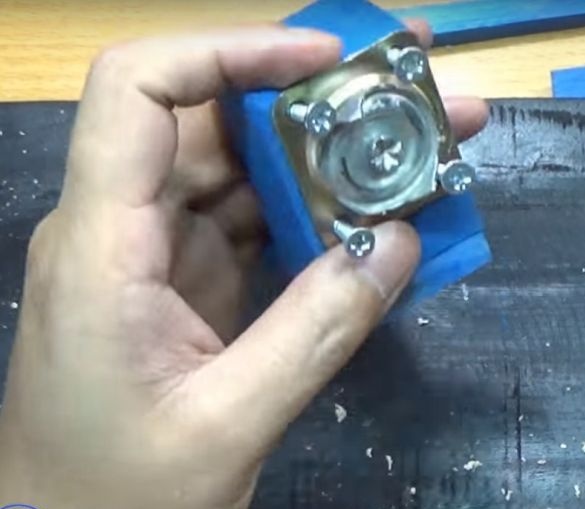

Corner metal mount.

Also, the author will need a small electric motor (maybe not working).

Another collet chuck.

Furniture wheel.

A pair of wires and a switch.

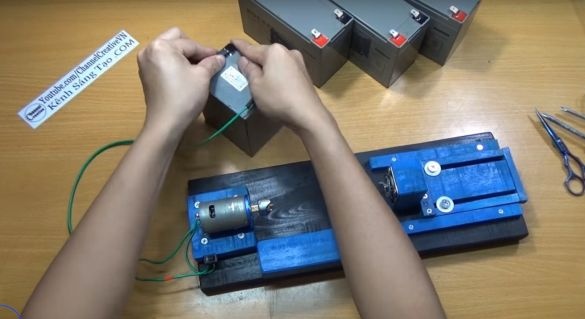

And of course the battery as a power source for a mini machine.

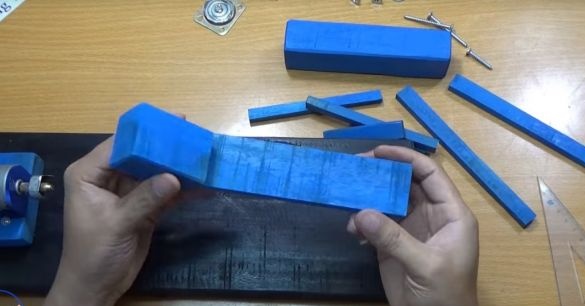

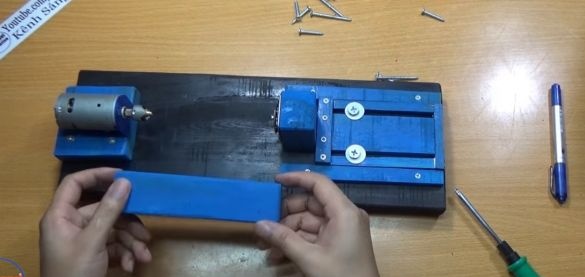

Also, the author will need a few boards. From them he will make blanks of such sizes for the future mini-lathe.

After the blanks were cut, the author painted them.

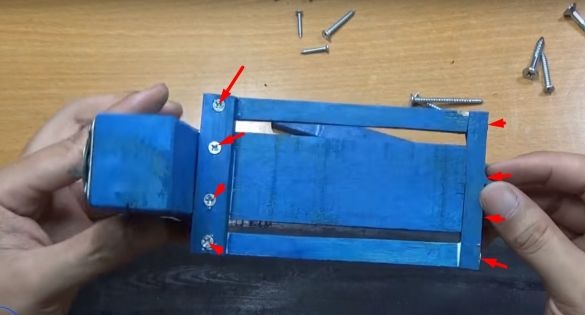

The basis of the machine body will be the largest wooden blank, the author will screw a 7 × 7 cm square blank to it.

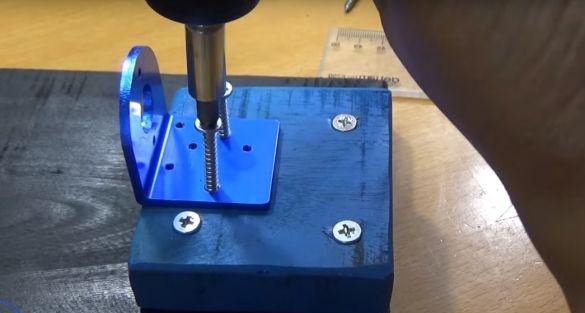

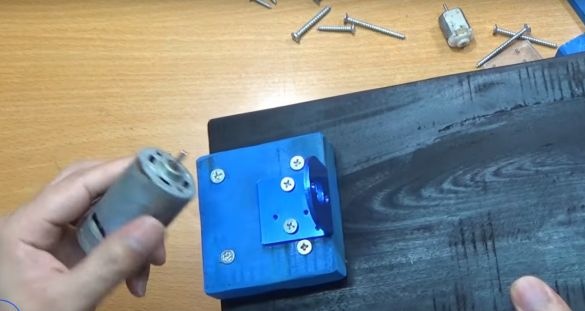

He screwed a metal corner to the square blank, and strengthened the electric motor on the corner.

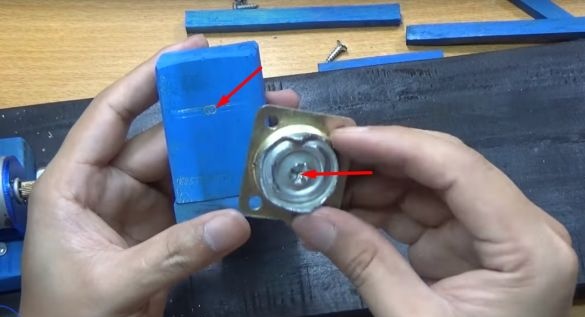

The author will make out a small motor, he will only need a body.

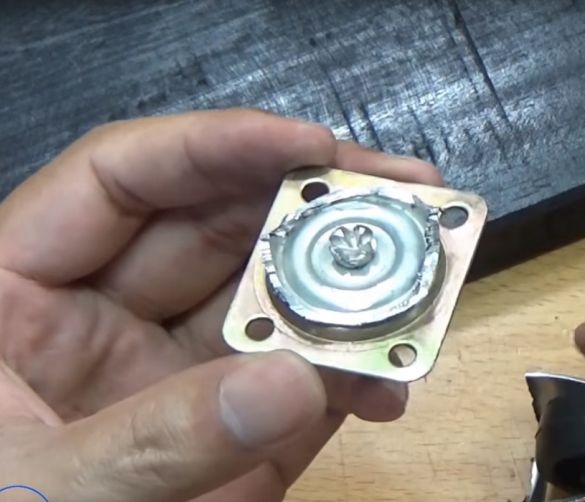

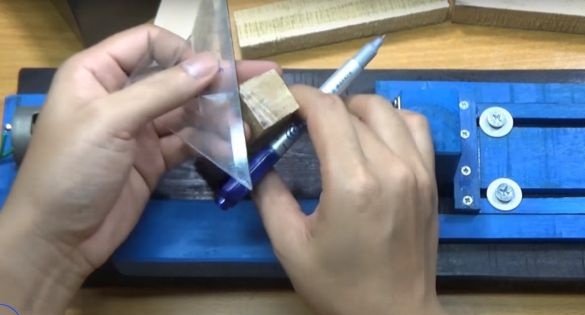

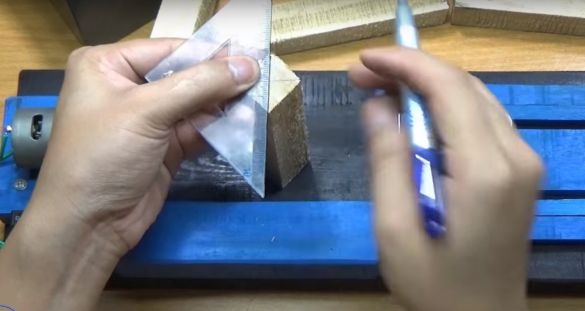

Then the author will remove the nut from the cartridge and make a hole in the casing from the small motor for its size.

Further, on the case, the author marked up and cut off everything unnecessary.

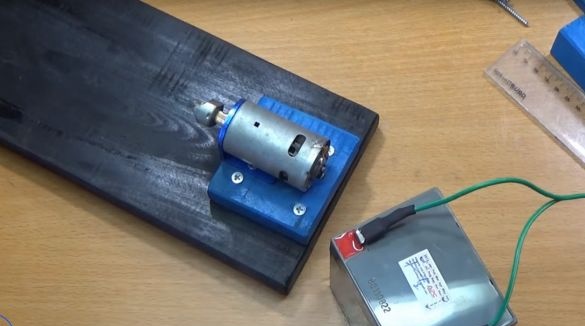

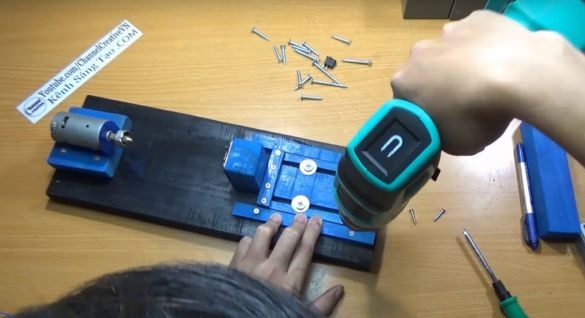

Next, I installed a cartridge with a housing on the axis of the engine, connected a power source by checking the operation of the engine.

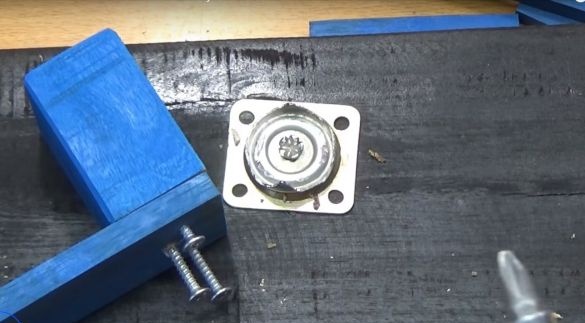

Further, from the furniture wheel, the author also cut off everything unnecessary.

Having removed the sharp edges of the slices, he well greased the resulting part with oil.

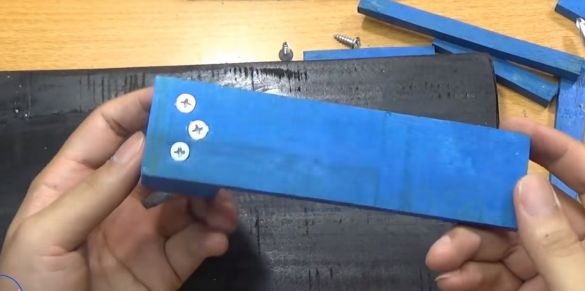

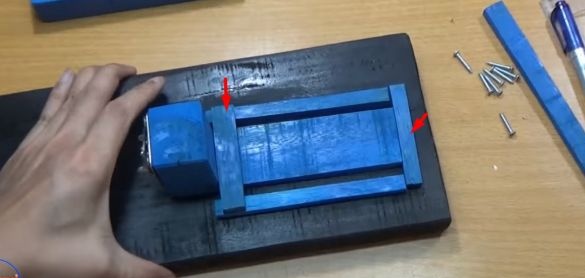

Next, the author prepared 3.5 x 5.5 cm blanks to 4 x 15 cm blanks.

After noted the place where there will be the center of the tailstock.

Then he marked the places for fastening the tailstock and made holes in these places, the size of the holes is slightly smaller than the size of the screws that will be fixed. And fixed it.

Putting the finished part on the base so that the front and rear headstock are parallel to each other.

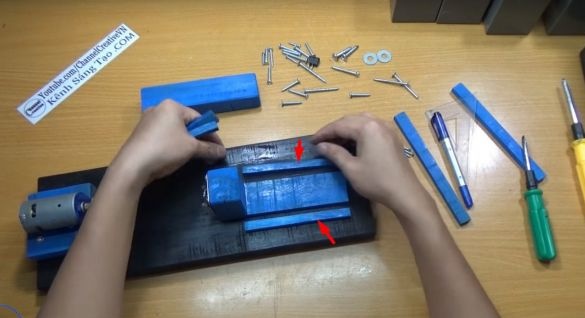

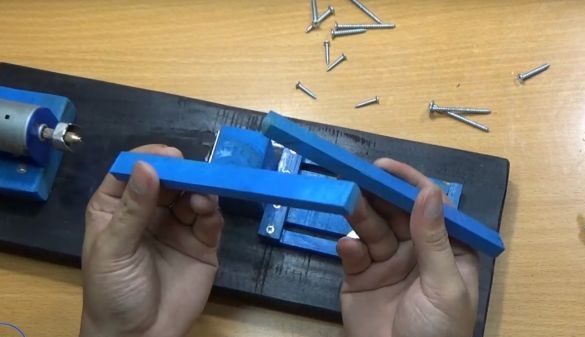

Further, the author took blanks of such dimensions 1 by 7 cm, 1.5 by 7 cm, and two blanks 1 by 12 cm., And laying them down I screwed them with screws as shown in the photo below.

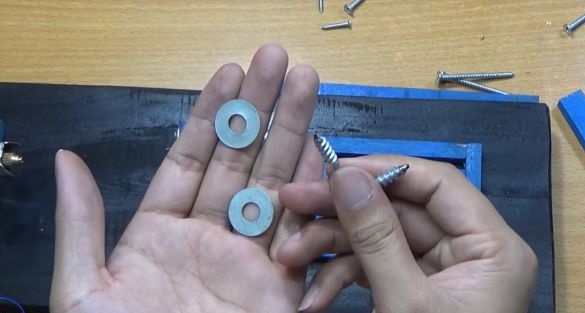

Then he took the washers and screws and made a hole in the base for them.

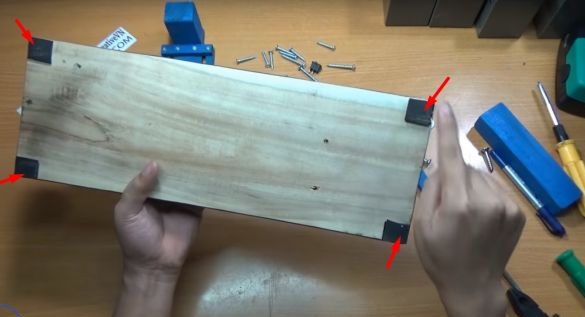

Also, the author glued pieces of rubber on the corners for stability of the machine.

Then I screwed the screws into place.

Then the author took two blanks 1.5 by 16 cm. And screwed them as shown in the photo.

At the end of the assembly, the author took the last blank, and screwed it to the base, it will serve as a handyman.

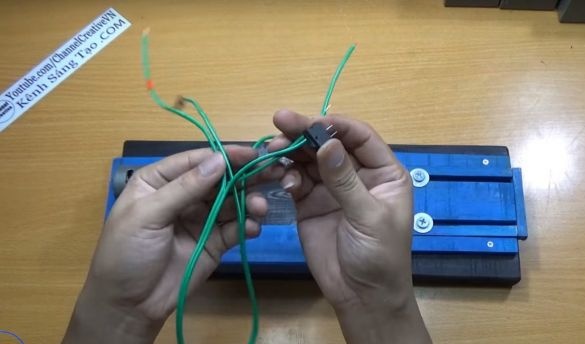

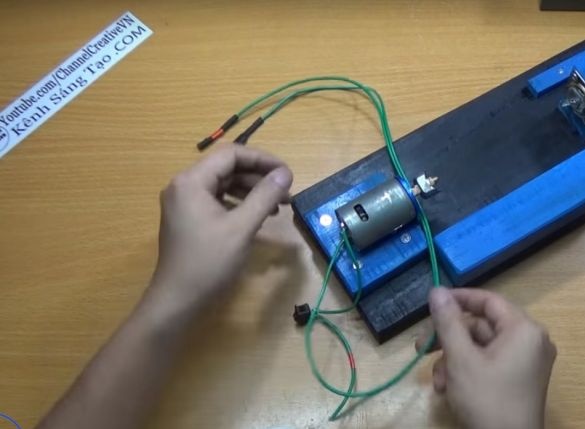

Then the author proceeded to the electrical part, for this he took the wires and soldered them to the engine, letting the plus wire through the switch.

The author secured the switch to hot glue.

The ends of the wires connected to the battery.

Such a mini wood lathe turned out by the author.

And at the end of the test.

Thank you all very much. See you.

Machine video: