Hello everyone, if you want to get a stove for yourself, but life circumstances do not allow the use of firewood, this is not a problem, you can make a stove on gas. In this case, there will be no smoke, dirt, ash, neither coal nor firewood will be needed, only a small cylinder with propane will be enough.

Our author decided to make such a furnace. As a basis for the body, he decided to use a beer barrel. It is made of fairly thick stainless steel, which allows it to not burn through for a long time and maintain a brilliant appearance. Of course, in such an oven you won’t be able to cook bread, but pizza and other instant dishes can be cooked without any problems.

Materials and tools used by the author:

Material List:

- a barrel of beer;

- corner;

- thick sheet steel;

- refractory cement;

- stainless steel rod;

- fittings, faucet, thread sealant and other parts for gas equipment:

- gas cylinder.

Tool List:

- ;

- ;

- .

Furnace manufacturing process:

Step one. We make the spiritual part

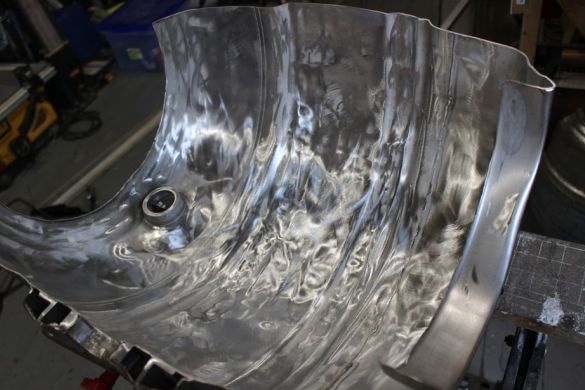

To begin with, we will manufacture exactly the part of the furnace that will hold the temperature. Its author makes from a beer barrel. To do this, take the grinder and cut the barrel along. Next we need a grinder with a wire brush. Using it, we carefully process the workpiece, you need to clean off all the dirt, stickers, etc. Otherwise, when the furnace is heated, all this muzzle will smoke very much.

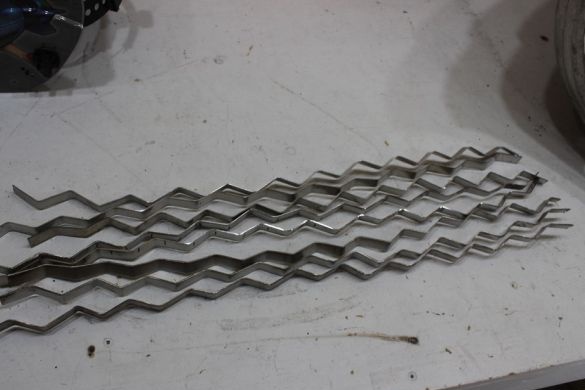

Next, we need steel plates, they will need quite a lot. It will be a kind of ribs that will not allow cement to fall off. We weld these ribs to the inside of the furnace. The more they will be, the more reliable the heat-resistant coating will hold.

Once the ribs are ready, you can knead the cement. Cement will need heat-resistant, as it must withstand high temperatures. The author pours cement, so it needs to be made quite fluid. First, pour one half, and when the cement sets, you can pour another. The result is a strong, high-quality coating. Even if due to different expansion coefficients the materials will peel off, the coating will be held on the ribs. We need to cement all open areas of metal.

Step Two Frame manufacturing

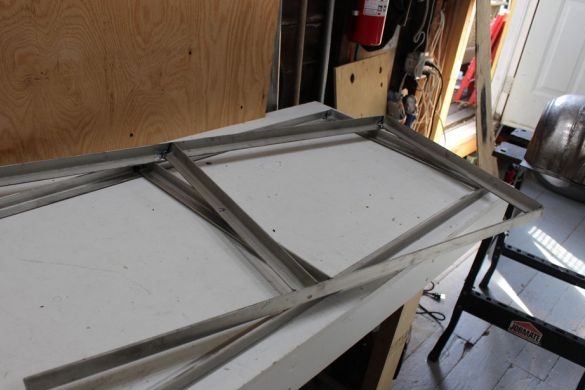

Under the oven, we definitely make a strong frame and also preferably made of stainless steel, but you may have problems welding some steel grades. Ferrous metal can also be used by painting it with heat-resistant paint. As a material for the frame, the author used corners. Just cut them to the desired size and weld.

For convenient movement of the furnace, the author installed castors on the legs. In the upper part, a steel sheet is installed, on which the furnace is then installed.

Step Three First design, wood version

The very first version of the author’s stove worked on wood, for this a special miniature stove was made, which heated the furnace. Such a furnace can be made of square pipes of large cross-section. The furnace is installed on a countertop made of sheet steel, and the furnace is installed below, the pipe is inserted into the furnace. But in the future, the author changed the design, now it works on gas, and also with the help of two burners the floor is heated, which allows to obtain a higher temperature in the furnace with less time.

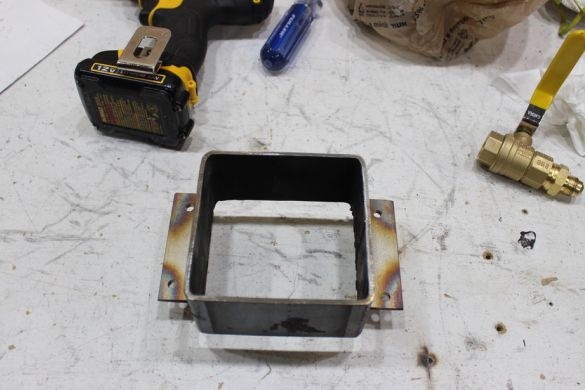

Step Four Main burner

First of all, the author made the main burner, from which the flame enters the furnace and heats it. For its manufacture, steel pipes for supplying gas were needed, as well as a piece of pipe of a larger diameter for the manufacture of the burner itself. How exactly everything is going, look at the photo.

Step Five Underfloor heating and furnace mounting (completion)

Now we will arrange the heating of the bottom, for this the author used two pieces of pipe, it is best that they are also made of stainless steel. In the pipes we cut slotted holes with a grinder. Install the burners in the right place, they are connected through a tap. As a result, you can turn on these burners only if necessary. Carefully seal all threaded connections so that gas does not pass anywhere.

For fastening the furnace, we need small steel plates with holes. Just weld them in the right places, and then fasten the crucible with the help of bolts and nuts to the base.

For a sheet metal furnace, make a door that will allow you to close the oven and warm it up. At the bottom of the frame also weld a shelf, here you can install a bottle or place various kitchen utensils. That's all, the stove is almost ready, do not forget to buy an electric lighter with a long nose, so that it is convenient and safe to burn gas.

Step Six Testing

The oven is ready, you can test! Everything is individual here, it all depends on the type and thickness of the dough. The author, during the first tests, burned his pizza in just 30 seconds, since the bottom was very hot. According to the author, the temperature inside the furnace can reach more than 500 ° C. For such a furnace, it is necessary to install a furnace thermometer. With it, you can understand how long and at what temperature you bake pizza. Generally speaking, it takes about 1-2 minutes to cook pizza, depending on the temperature. But the longer the food is prepared, the better it is, it is important to remember.

In conclusion, the author noted the fact that it is not at all necessary to use a protective coating of cement, since heat capacity is not important when using a gas burner. In his opinion, using a gas burner, you can also cook bread and other dishes. And thanks to the underfloor heating in such an oven, you can fry something, such as roasting the bottom of a pizza. That's all, the project is over. I hope you liked it, and you found something new for yourself, good luck in manufacturing!