In this article, we will look at how to make compact folding goats. Such goats take up little space during storage, are convenient to use and easy to install. On top of the goats, you can put a sheet of plywood and get a table, and laying boards to get a workbench. They can be easily moved and installed in a new place. For their manufacture, the master used the following

Tools and materials:

-Profile;

-Metal square;

-Board;

-Door hinges;

-Door hooks;

- Plugs for profile pipe;

Self-tapping screws;

-Ushm;

-Welding machine;

-Roulette;

-Marker;

-Glomer;

-Gon;

- Clamps;

-Drill;

-Electrodes;

-Drill;

-Primer;

-Paint;

-Brush;

-Varnish;

Step One: Cutting

Cuts material to size.

Cleans the profile from rust.

Step Two: Template

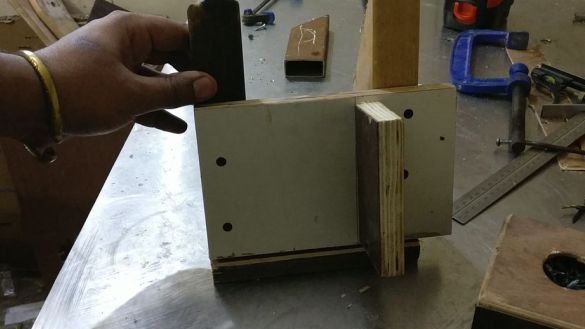

The profile will need to be welded at a certain angle. Since the master makes several goats, he makes a template for welding the profile.

Step Three: Feet

Cuts off the edges of the legs at an angle of 15 degrees.

Step Four: Welding

Starts welding work. As can be seen in the photographs, a rectangular pipe is welded to the square profile pipe at an angle. A square is welded at the bottom of the rack.

Step Five: Loops

Racks are welded and now you need to connect two racks with loops. The master welds the hinges to the inside of the posts. Trims legs.

Step Six: Board

From the board, the master makes stubs on the transverse rectangular pipe and linings. It polishes and lays two layers of varnish on the wood.

Seventh step: painting

Primers and stains goats.

Step Eight: Final Assembly

Drills holes and bolts wooden lining to the top of the goat. Installs wooden plugs. Installs rubber plugs on the legs.

The goats are ready.

In more detail, the manufacturing process, you can see the video.