This article is not an advertisement. Just a demonstration of cool solder.

Solder for aluminum alloys. HTS-2000, aka CASTOLIN 192. This is a new generation of solders for brazing aluminum alloys.

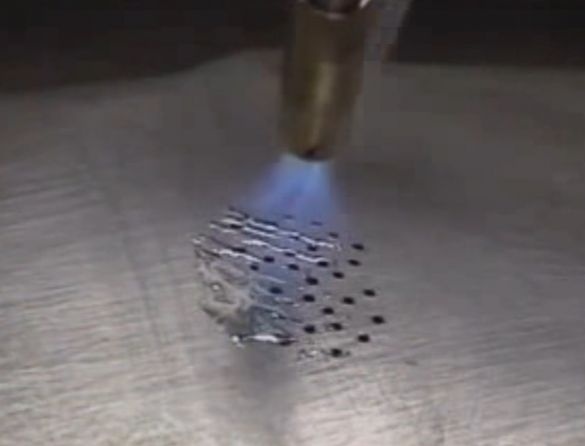

Solder has high corrosion resistance and adhesion to aluminum alloys. Solder is easy to use. It is necessary to prepare the part, apply a little solder.

Brush for better grip.

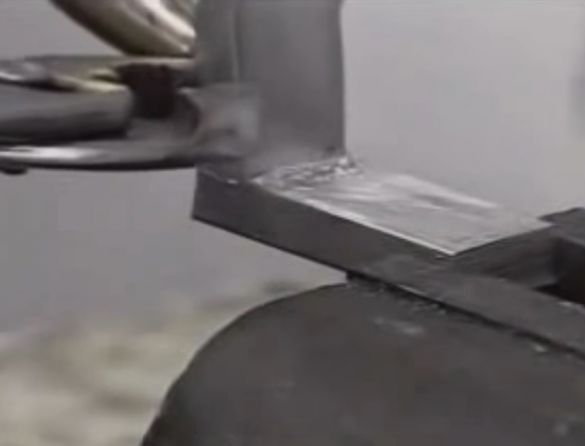

Connect the details.

After cooling, you get a connection with the strength of professional welding.

HTS-2000 does not require expensive equipment. Repairs can be made even in the field. Roughly hammer with a hammer to check the quality of the seam.

All this takes the repair of aluminum alloys and products from them to a whole new level.

Is the thread broken? With the HTS-2000, repair is easy.

We drill the old thread, fill it with solder.

Immerse the bolt.

After cooling, we get a new thread.

Check the resulting thread for strength.

We will tighten the bolt until the thread is broken.

It can be seen that the steel bolt with a diameter of eight millimeters was inferior in strength to the thread from HTS-2000.

A difficult case. A part of the bracket broke off.

Part replacement is usually required. But with HTS-2000, such repairs are also possible.

We form the missing part from the solder.

After cooling, the solder has good machinability.

Let's do a simple test. We apply several blows with a hammer on the repaired part.

The bracket is broken. But, having looked closely, we see that the kink occurred on the base metal, and not on the seam.

The fixing eye is broken off.

We will repair it. And also conduct a simple test.

We apply a few blows with a hammer.

It can be seen that the eye is strong enough.

Crack in the housing.

Solder is ideal for repairing such damage.

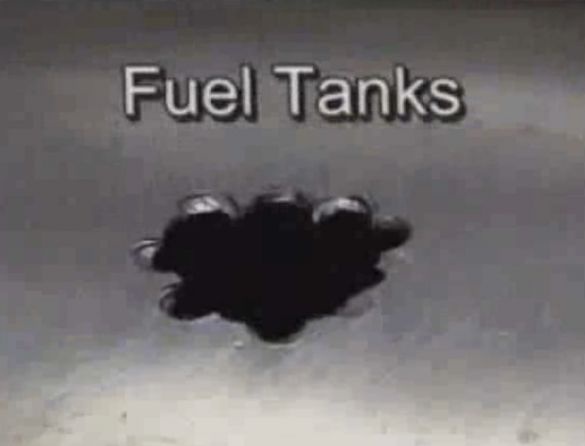

Multiple damage in the housing. With the HTS-2000, such repairs become simple, reliable and inexpensive.

The strong surface tension of the solder allows you to reliably overlap large holes and holes.

Major damage is repaired with patches.

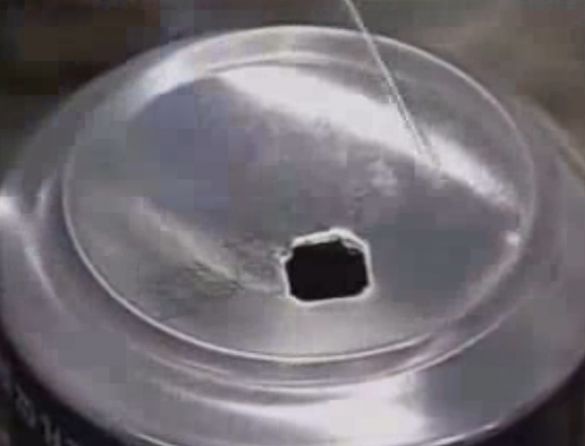

Another demonstration of solder capabilities. Make a hole in the beer can.

And fill its breakdown with solder.

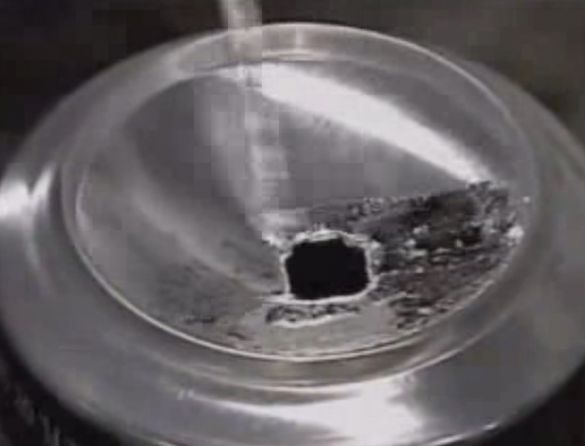

We carry out a simple strength test. We cut the jar and try to punch the hole in the opposite direction.

Solder in this case also passed the test.

Damage to the air conditioning tube.

Also quite easy to fix.

Damage to the cylinder head. It can also be eliminated with this solder.

Test of strength.

All high-quality soldering!

Link to the original video - under the text is the "source" button.