Hello everyone, I present to your attention a very simple to manufacture. With it, you can make handles for tools, grind and so on. Everything is done quite simply, as the basis is used the engine from the washing machine with a power of only 180 watts, which rotates at a frequency of 1425 revolutions per minute. Such engines were used in many Soviet washing machines. Although they are already quite old, similar motors serve for quite some time.

Materials and tools used by the author:

Tool List:

- grinder;

- welding machine;

- measuring tool;

- drill.

Material List:

- square pipes;

- Sheet steel;

- the engine from the washing machine (180 watts);

- bolts, nuts, washers, threaded rods and other little things.

Manufacturing process:

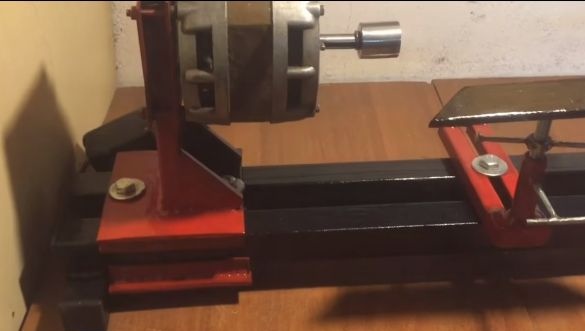

Step one. Base assembly

The author used square tubes as a basis. Thanks to their shape, we get excellent guides. We cut the pipes, clean, and then weld the structure.

Step Two Bracket for engine

To fix the engine, we need a rack. Its author does, by welding two pieces of square pipes. We weld a square plate with holes to the rack, to which the engine will be mounted.

The stand itself is welded to a piece of the channel, and the whole thing is mounted on the frame movably by screwing it with bolts and nuts. On the other side of the guide, a similar section of the channel is installed.

Step Three Grandmother

We weld the headstock from sheet steel, and so that it goes along the guides, we need square pipes of a slightly larger diameter than we used for the base. Cut them, weld and get an excellent moving platform.

Step Four Cartridge

A cartridge is welded to the motor shaft, we make it from a piece of a round steel pipe. It is advisable to grab the part to start with welding and twist the shaft, it will immediately be seen if there is a runout. Well, if everything is smooth, then you can weld and finally.

Step Five The hand of

From sheet metal and threaded rods we assemble a handicraft.At the author, it can be adjusted in height, and you can also change its angle. If there is no suitable sheet steel in thickness, you can cut it from a channel or a corner.

Step Six Rotating headstock

The thrust piece on the headstock must rotate with the product. To make this rotating emphasis, the author adapted two bearings, which were installed in a piece of a round pipe. Further, the whole thing is welded to the axis of the headstock, at the end you will need to install a sharp tip. To make it convenient to clamp the product, the author screwed a large aluminum handle from the water tap to the headstock.

In the end, you will only have to paint the machine so that it does not rust and looks good.

That's all, homemade ready, I hope you liked the project. Good luck and creative inspiration, if you decide to repeat it. Do not forget to share your homemade products with us!