Hello everyone, I bring to your attention a reliable, sturdy, beautiful knife in the Bowie style. These knives can be classified as combat, they have a large strong blade, which allows not only to effectively cut, but even to cut with such a knife. With such a knife, it will not be scary to be in the forest, you can also take it with you on fishing, on a hike, and even going out of town as a whole. The knife looks high-quality and beautiful, but it is made exclusively by hand. Here the author also used forging to give the main form. Thanks to forging, steel becomes even stronger.

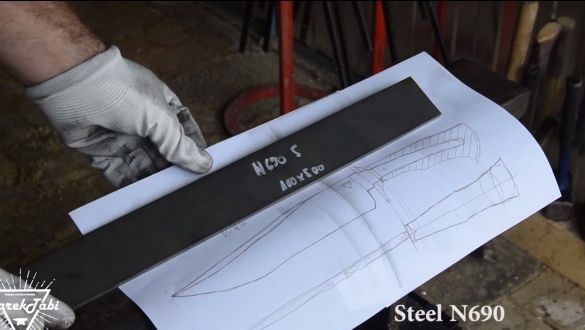

The author made a pen from the horn, and as for the blade, N690 steel was used here. This steel is similar in composition to 440C, but its feature is that there is more cobalt and molybdenum. As for the most important element of carbon steel, then it is already 1.08%, due to this, high metal strength is achieved.

Also in this brand there is 17.3% chromium, which increases the resistance of the metal to rust.

Such steel has uniform strength in all areas, including the cutting edge. This metal is commonly used in the manufacture of really strong and high-quality knives. So, let’s take a closer look at how the author managed to make such a wonderful knife!

Materials and tools used by the author:

Material List:

- horn for the handle;

- sheet brass;

- a piece of steel N690 or similar;

- brass rods for pins;

- epoxy adhesive;

- leather for sheath.

Tool List:

- forge furnace;

- belt sander;

- drill;

- blacksmithing supplies;

- grinder;

- grinder;

- vise;

- files and sandpaper;

- oven, blacksmith furnace, oil (for hardening).

Bowie Knife Making Process:

Step one. We form the main profile

First, we will make a template, according to which we will make our knife. You can draw it by hand on paper, or you can print it on a printer by looking for an interesting drawing on the Internet. The author decided to make the main profile one of the most ancient ways - by forging. We preheat the workpiece and work with a hammer on the anvil. Thanks to forging, we additionally strengthen the metal.

Having formed the blade, the author cut off the excess and then pulled out the handle. An electric hammer has already been used for ease of operation. The more carefully the profile is forged, the less then will be the grinding work.

Step Two Grinding work

Half the job has been done, now we are starting grinding, thanks to which we will finally form the desired knife profile. First, we go through the contour with a grinder, using a grinding wheel. Well, then we process the planes, for such purposes, a belt sander is perfect. You can also go through the completion manually using sandpaper.

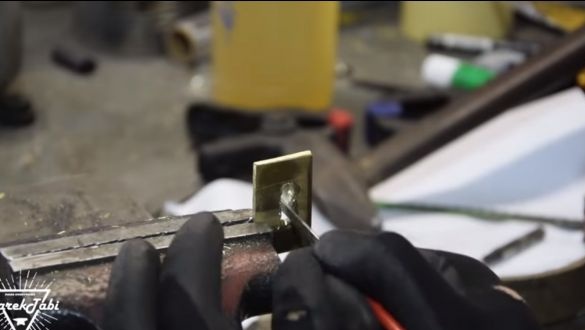

Step Three Making guards

The guard on this knife, by analogy with a saber, that is, protects the entire arm from the beginning to the end. For its manufacture, the author used brass. Cut the desired length of the workpiece and bend it to the desired profile. The author drew a profile with chalk on the anvil and shaped the product by eye. In the guard we cut a slit hole for the tail of the knife, the author does this with a drill and file. In front of the main guard there is another additional small one.

Step Four We form bevels

Bevels need to be formed on the knife. The author makes them as wide as possible, so the blade will be smooth, and the knife will cut perfectly. The author forms the bevels by eye using a belt sander.

If you are not confident in your abilities, you can pre-mark everything up. It is also recommended to draw a center line along the blade to remove an equal amount of metal from both sides. Here you will need a vernier caliper or drill of the same diameter as the thickness of the blade.

Step Five Make a pen

The author made a pen quite interesting, he decided to use a deer horn for these purposes. If it is difficult for you to find such material, you can easily use a tree, you can also choose an interesting piece of branch in shape. We select the desired piece of horn and cut it, grind it on a belt grinder, where it is required.

In total, this handle will be fixed with four pins, which are used as brass pins. Also inside the horn we need to cut a slit hole under the knife shank.

Step Six Blade Heat Treatment

Next, we have to harden the blade so that it holds the sharpening for a long time and withstands heavy loads. To begin with, the author decided to put a mark on the blade, heating it to a red glow. This allowed us to normalize the metal after forging.

Well, now you can harden and heat the blade and dip in oil. If hardening is successful, the blade should not be taken with a file.

As a result, such a procedure as vacation is still to be done, it must be done without fail. Thanks to tempering, the metal will not be brittle. To do this, send the blade into the oven for about an hour and a half and heat at a temperature of 200 ° C. You can understand whether a vacation has taken place by the color of the blade. Usually it becomes a straw color.

Seventh step. We prepare all the necessary components and assemble the knife

After heat treatment, the blade will need to be sanded with fine sandpaper, as the metal will be in scale. To make sandpaper work better, we wet it in water, so it is better cleared of dirt.

Also cut the pins to the desired length. The pin that is installed on the end of the handle must be riveted in advance in a vice. Brass parts can be polished, since then it will be more difficult to do.

That's all, the knife can be assembled, for this we need a good epoxy resin. Pour a little into the handle, and also apply glue to the brass parts to be glued together. Including the pins you need to sit on the glue. We remove the excess protruding glue and then let it dry. Usually, the adhesive sets confidently after 24 hours. After that, the knife will be ready, it can be sharpened to the state of the blade. Here you will need a special grinding machine or grindstones. Many craftsmen use Japanese water stones. In extreme cases, you can sharpen the knife and fine sandpaper. The author’s knife was so sharp that it easily cuts a canopy of paper.

In addition, with a knife you can also chop boards, sticks and so on, the blade can easily withstand such loads.

Of course, for such a sharp and large knife, sheath must be made. Make them not difficult, you will need leather and sewing accessories. The author made excellent scabbard.

That's all, I hope you liked the project. Good luck and creative inspiration if you want to repeat something like that. Do not forget to share your homemade with us!