This article will be useful to everyone who has to press out bearings. Be Creative creator will show how he made the simplest device for these works. Homemade is very simple and does not require any sophisticated tool. Materials also need a minimum. The dimensions of the device can be selected to fit your needs.

Materials

- 3/4 inch pipe cut

- Two washers with an external diameter of 3/4 inch

- Hairpin M10

- Two M10 nuts.

Instrumentsused in the manufacture of homemade products.

- Welding machine

- Grinder, grinding wheels and conventional metal discs

- Vise

- White clerical corrector.

Manufacturing process.

The author begins with the manufacture of the device body. To do this, he needs a small piece of 3/4 inch pipe. Marks the corrector future places of the cut.

Clamps the workpiece in a vice, cuts out with a grinder as planned.

"Crocodile" removes the trim.

Turns the workpiece over, puts a washer on its lower (in the future) part and welds it.

Using a grinder, cuts out a future capture.

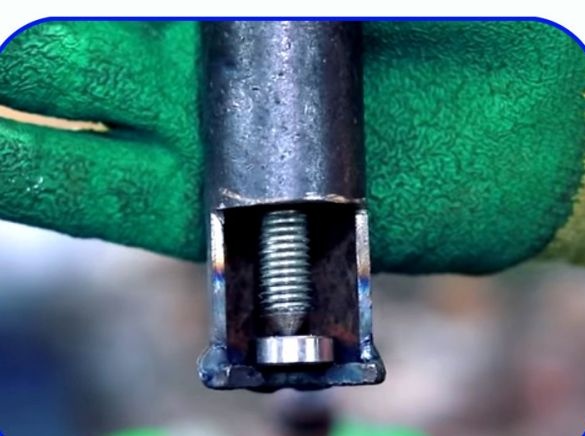

He takes an M10 stud and nut. Now, to another washer, holding it in a vise, welds the nut.

Sharpen a hairpin, it will be a pusher.

To the second, upper part of the pipe, a washer is welded.

As a result, the author for some 15 minutes turned out a ready-made tool. Here you can see that at the end of the stud another nut is welded, for which the author will twist the rod.

A few tests, an attempt to remove the bearing from the motor shaft. To remove the bearing - rests the rod on the motor shaft and, rotating the rod with a key, removes the bearing. It is removed and remained intact.

The second attempt, with a smaller bearing. Everything is also successful.

Homemade can be cleaned with a grinding wheel and spray painted. Perhaps it would be convenient to make a pen at the end of the stem rather than use a key. But so - compactly turned out.

Thanks to the author for the idea of the right instant cooking tool.

All obedient tools!