Good day to all.

To make this tool, the author took a 10x10 mm steel square.

Metal strip.

The handle of the old file.

And a cloth from a hacksaw.

The square cleared of old paint and rust.

Then he made the markup.

Nakernil.

And he made two holes with a diameter of 3 mm.

In one of the holes, the author cut the M 3 thread.

Next, try on a jigsaw file.

Everything is perfectly fixed.

After the author will make a mount for the hacksaw blade.

To do this, he will make one slot here.

And one in this place.

After trying on.

Further, the author will fix the square in a vise, and putting a profile pipe on it will bend it at an angle of 90 degrees.

Irregularities resulting from bending.

The author will delete it with a file.

Next, shorten the workpiece to the desired size.

For the next detail, the author took another piece of the square.

And he made a 3 mm hole in the end of this billet.

After making a cut, to fix the canvas.

And also made mounts for a jigsaw file.

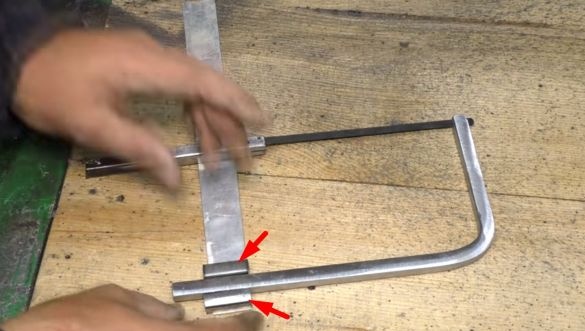

Trying on finished parts.

And the manufacture of another detail. The author decided to replace the steel strip with aluminum, since it is easier to process.

Having measured a piece of the right size, the author will cut off the excess, and he will need 2 pieces of such details.

To fix the movable part of the tool, the master took two small pieces of the same square.

Clamping both strips and a piece of the square in a vice with a manual clamp, he will make through holes for the bolts.

Install the bolts in place.

Fixing them with nuts.

After it will try on, and mark the places of attachment of the second piece of the square.

Similarly, clamp the parts in a vise.

And make holes.

After installing the bolts, the part looks like this.

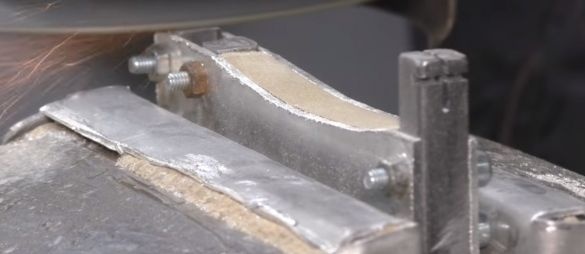

In the empty space between the plates, the author will install a piece of the doorway, which he left after repair.

After it will process everything with a file.

And angle grinder.

After rough processing, he will remove all roughness with sandpaper.

And proceed to install the handle.

To do this, he will fix the part in a vice.

And grind the edge to the desired size.

And putting a pen on the turned edge of the square.

Taped it with epoxy.

Such an instrument, it turned out today from our master.

Left to experience homemade. First, the master installs the nail file.

Will stretch the canvas.

And now the test.

After it removes the blade and installs a jigsaw file.

As a result, the tool copes with its tasks perfectly, besides we all know that working with a tool do it yourself much nicer.

And that’s all for me. Thank you all and see you soon!

Video: