Hello dear readers and the inhabitants of our site!

In this article, the author of the channel "Cactus! Workshop" will show you how he solved the problem of a mobile hook for a profile pipe. His task was very simple. In his workshop, under the ceiling, structures from profile pipes are installed, which he uses to hang various parts and tools. At first, the author had to press the hook with a clamp. But I wanted the hook to lock automatically and be able to move along the pipe. The solution came by itself when he accidentally clicked off the clip and everything fell. Hence the author’s name for this homemade product is the gravitational hook.

Materials

- Steel strip 30 mm.

- Three nuts M12.

- M10 bolt, nut with lock ring.

Instruments, used by the author.

- Welding machine

- Drilling machine

- Bulgarian

- Disks for metal

- Petal stripping disc

- Pliers clamp with fixation

- clamp pliers with fixation

- Corner

- Vise

- metal brush

- Kern, the hammer

- White marker.

Manufacturing process.

First of all, using a corner, marks a steel strip with a white marker.

Cuts marking lines using a grinder and metal disc.

Then it fixes the strip to the table with a clamp, and cuts the first line almost to the end.

Further, clamping with ticks, bends the edge at 90 degrees. Boils it and knocks the scale with a hammer.

It performs the same actions with the rest of the fold lines, only it bends with the help of clamp mites. And at the end, he brushes the seam.

Cutting off from the main strip, the author got such a first detail.

With the second part, all actions are similar.

Trying on a profile pipe and both parts. Almost everything fits.

Lays two washers between the workpiece and the profile, thereby creating a small gap.

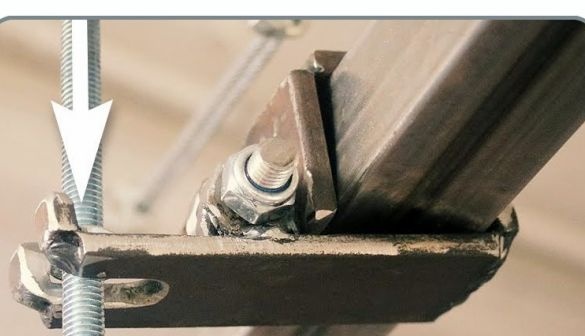

Three nuts M10 spreads along the junction of the workpieces. The extreme nuts are welded to the lower part, and the middle one to the upper.

Using a petal stripping disk, smooths out all irregularities and sharp parts.

Kern marks the place for the hole, then drills it on the machine, clamping the workpiece in a vice.

Starting from the edge of the workpiece cuts through the grinder to the hole.Then, turning the part in a vice, aligns the edges. It turned out the so-called "plug". It will be convenient for her to move the hook along the profile using a long stud with a nut. For the same hairpin it will be possible to hang something. At the end, additionally processes with a file.

That's all, both parts are ready. That's how they are going.

Insert the M8 bolt and tighten the nut.

Device done.

This is how this hook will work. Raising the hairpin - it moves easily along the profile, and lowering it - it is rigidly fixed.

Even having suspended a small rotary crane hook, it is already very difficult to shift to the side.

Thanks to the author for the interesting idea of a mobile hook!

Have a good mood!