I decided to make a simple vice from the channel and corners.

Material:

channel

corners

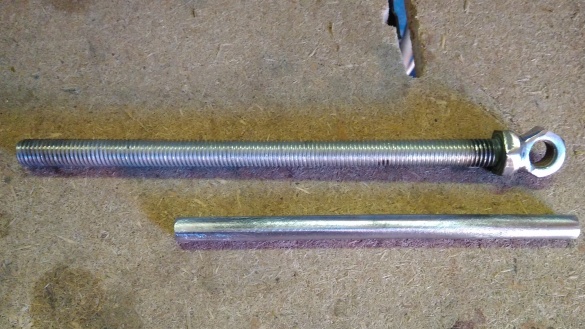

bolt

elongated nut

Tool:

Angle grinder

Welding machine

clamp

For business

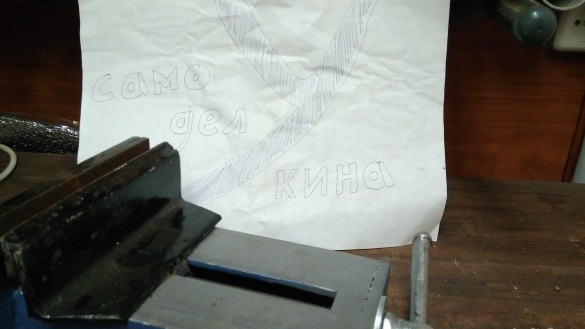

From the channel and corner I cut the details of the right size. ()

I put the details and figure out what should happen.

On one side, I placed a corner on the other with a strip of metal.

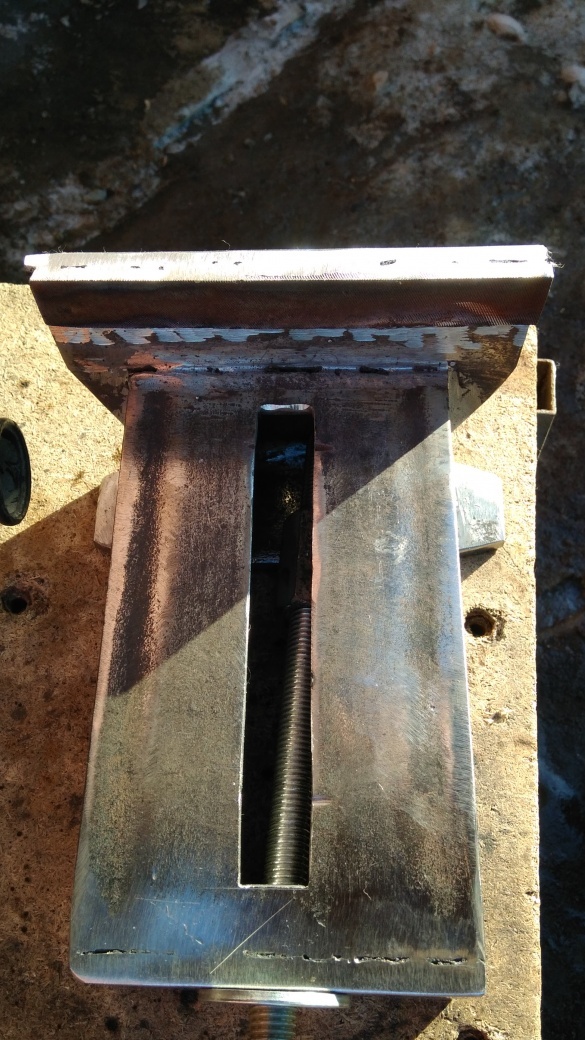

Then in the center channel I cut a groove with a “grinder”.

In a corner I drill a hole in the size of a bolt.

I cut off the excess from the channel.

I cut off another strip of metal from the corner.

I clean all the details.

I wonder everything in place.

I start welding.

I weld a corner with a channel.

I cut off excess metal parts to bevel.

In the plate, drill a hole for the bolt.

And I weld this plate to the other end of the channel.

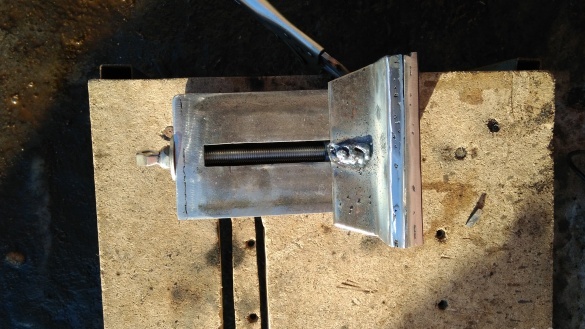

I cut a strip of metal into the size of the groove made in the channel.

Further to the elongated nut I weld a strip of metal.

I weld the usual nut for the screw to the bolt.

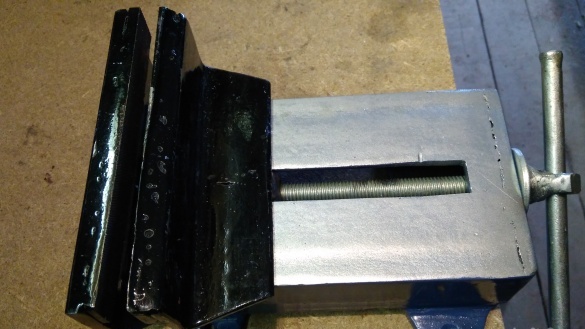

I am connecting the details.

I weld an old file to the corner, as sponges.

I’m clearing it.

Then in the corner I make a slot for welding.

And I weld a corner to an elongated nut with a welded strip.

I make a collar.

In a nut with a bolt, I drill a hole and insert a nail.

In the legs of the vise I drill holes for fastening the vise with screws to the table.

I paint the product.

Bye everyone.