Self-tapping screws are fasteners similar to screws, but, unlike them, are screwed into the material without first being drilled. Despite the simple principle of their application, there are some tricks to make working with self-tapping screws more convenient where it is difficult to use them. Consider a few of these secrets.

How to choose the right screwdriver tip

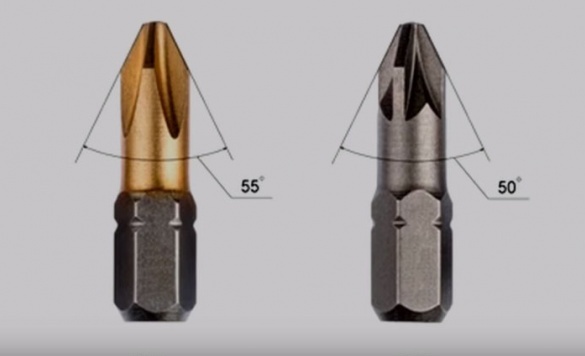

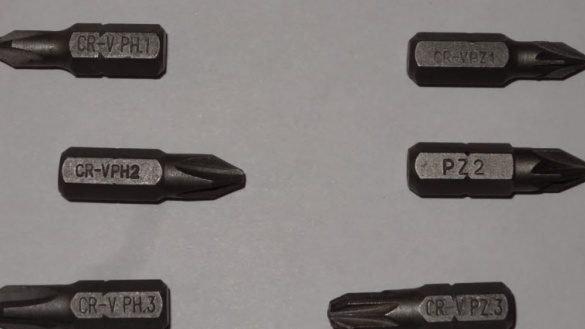

Currently, the heads of almost all self-tapping screws have a cross-shaped notch, and screwdrivers with a nozzle in the form of a bit made “under the cross” are used to screw them in. There are two types of cross bits - PH and PZ. The first is the standard 4-slot bits, and the second is the 8-slot upgraded bits. PZ nozzles and self-tapping screws are more convenient, since, practically, they do not allow the screwdriver to break off during operation from the hardware head.

In addition, choosing a screwdriver bit, it is necessary to take into account its size, which is indicated directly on the product. Today bits of sizes 1,2 and 3 are used. Correctly selected type and size of a screwdriver bit ensure its tight fit into the slots of a self-tapping screw.

How to screw a long self-tapping screw into a solid material

Screw a long screw into a dense material is not easy. If you screw such a hardware without preliminary drilling, then you can either break the slots on its head or break it.

In order to prevent this from happening, it is recommended to lubricate its threads with paraffin or plain soap before screwing it in. Lubricated, it will enter the material smoothly and easily. In the same way, you can do it when you need to screw a thick self-tapping screw into a narrow dowel.

How to screw a self-tapping screw into a thin block so that it does not crack

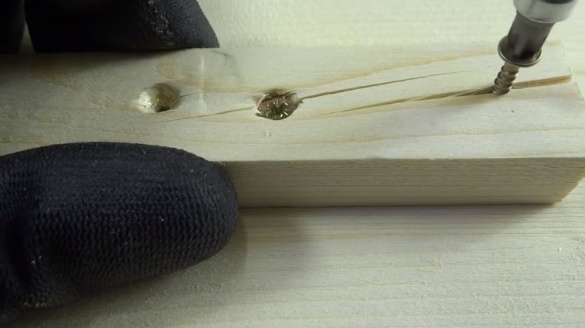

When screwing a self-tapping screw into a thin and narrow block or board, especially close to the edge, the material may crack.

The only way to avoid this is to pre-drill a hole in the screw-in point.

At the same time, sometimes a block breaks when trying to “drown” the head of an already screwed hardware in it. In order to prevent this from happening, it is recommended to countersink the hole for the self-tapping screw with a wider drill.

How to work with small screws

It is difficult to hold small hardware with your fingers. For convenient work with them, a special magnetic bat can be inserted into the screwdriver, and if there is none, then the usual one by attaching a small neodymium magnet to it.

You can get a magnet, for example, from old headphones or tear off the hooks of a faulty roulette.

If it was not possible to find the magnet, then you can fix the small hardware on the bit using masking tape, puncture it with a self-tapping screw from the adhesive side and simply stick it to a screwdriver.

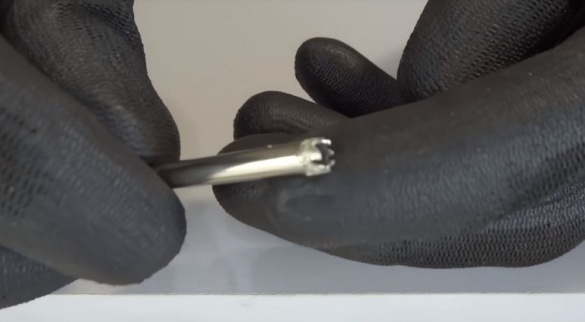

How to unscrew a self-tapping screw, in which the slots are torn

Quite often, with inaccurate tightening of the self-tapping screw, the notch on its head is abraded and, if necessary, unscrew it, it is impossible to hook it with a bat. You can cope with this task using an extractor - a special fixturesliterally "biting into" frayed slots.

However, the extractor is a rather rare tool, therefore, in its absence, you can always try to remove the self-tapping screw with a “smooth” head using some proven folk method.

How to unscrew from soft material

If the screw is small, the material into which it is screwed is soft, and its slots are not completely erased, then you can try to unscrew it:

- laying a thin rubber or leather gasket between the slots and the bat;

- heating the material around the screw with an iron;

- heating his head with a soldering iron.

If these tricks do not work, then you can try more effective methods.

Using tin and a soldering iron

To unscrew a self-tapping screw with worn slots in this way, the head is treated with acid, a little solder is dripped onto it with a soldering iron and, until the tin has cooled down, a screwdriver bit or a screwdriver is installed in it. When the tin freezes, the screw, turning the screwdriver, twist.

With the help of "dremel"

"Dremel" is a metal-cutting electric tool, the set of which includes a nozzle similar to a disk for a grinder. This nozzle can be inserted into the chuck of a screwdriver, sawed with its help in the "smooth" head of the self-tapping screw new slots and unscrew it by inserting a screwdriver or bit into them.

How to unscrew a screw with a broken head

It is possible to unscrew such a broken hardware only if it connects two sheets of some material, for example, chipboard. To do this, first you need to drill a self-tapping screw from the first sheet using any hollow tube with a jagged crown at the end. Fit tubular drill for ceramics.

In order to prevent the drill from “walking”, but immediately “drill” it into the material exactly above the self-tapping screw, it is necessary to make a guide template with a hole and place it exactly above the self-tapping screw. After drilling a self-tapping screw, the first sheet is removed from it, and from the second it is unscrewed with pliers.

Working with self-tapping screws requires accuracy and does not endure haste. The main thing is to correctly select self-tapping screws for a screwdriver bit or, conversely, a tool for the existing hardware.

Video version of the article: