I welcome fans to craft, in this instruction we will discuss how do it yourself make a simple hydraulic vise. The advantage of such a vice is that it is very convenient to use, it is driven by the foot, as a result, both hands are free when working. It also eliminates the need to constantly twist and unscrew the handle, as in a mechanical vice. Such a hydraulic vice is faster than a mechanical vice.

Collect similar homemade not difficult, but keep in mind that you will need to cut rather thick sheet steel. The author used for this purpose his home-made plasma cutting machine. The heart of the device is a hydraulic pair, which consists of a pump and a hydraulic cylinder. How to make such a vice, consider in more detail.

Materials and tools used by the author:

Material List:

- thick sheet steel;

- hydraulic cylinder (5 tons);

- hydraulic pump;

- a hydraulic hose;

- springs;

- bolts;

- overlays for a vice;

- channel.

Tool List:

- plasma cutter;

- pendulum cutting machine;

- drill with drills;

- taps for threading;

- grinder;

- welding machine;

- clamps;

- belt sander.

The process of manufacturing a hydraulic vice:

Step one. Base plate manufacturing

Let's start with the base for the vise, it is also called the base plate. For its manufacture, you need thick sheet steel, cut off the piece that is necessary in size. For cutting, the author used his plasma cutting machine.

To fix the plate, you will also need to cut two "ears", in which the author then drills holes. Ears are welded to the base plate with a welding machine.

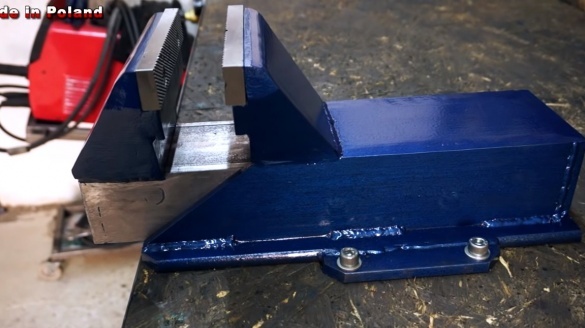

Step Two Internal movable part of a vice

Now we begin to manufacture the inside of the vise, to which the movable lip will be welded. The author used a thick-walled steel channel channel as the basis for this detail. We cut off the desired piece of the channel, and then we weld steel plates to it in order to obtain the necessary dimensions of the part. The point is to place a hydraulic cylinder inside this part. To weld the parts reliably, the author drilled holes in the plate and then boiled them. We grind welds well so that the vice does not wedge.

In addition, a plate with an opening for installing the hydraulic cylinder will need to be welded into the structure.

Step Three The manufacture of the outer part

The outer part of the vise is fixed, a second fixed lip is mounted on it. Also, this part is a guide for the inner, movable part of the vise. Here we will again need thick sheet steel, cut off three pieces and weld the structure. In order not to guess with the dimensions, we weld the outer part over the moving part. To get the necessary clearance between the parts, you can wrap the inside of the newspaper. We also weld the back, it will be used as a stop for the hydraulic pump, this part must be strong.

When everything is ready, proceed to grinding the inner moving part. First, grind it with a grinder, and then manually using sandpaper. When the friction surface is smooth, the risk of the vice jamming at a crucial moment is reduced. After fitting all the parts, everything can be finally and reliably boiled.

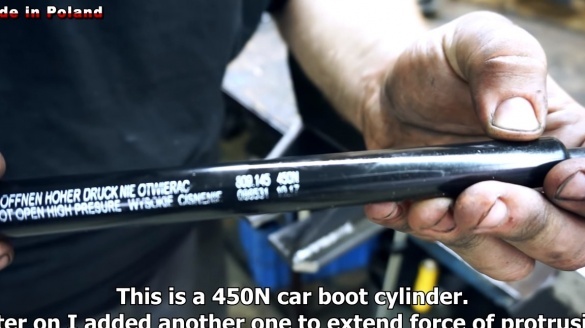

Step Four Hydraulic cylinder installation

Now you can install the hydraulic cylinder inside. On one side it will rest on the fixed part of the vise, and the other on the moving part. When the cylinder moves apart, the lips of the vice will close. To return the vise to its original open state, a spring is provided inside. The vise can be opened with one easy movement of the leg, relieving pressure from the system.

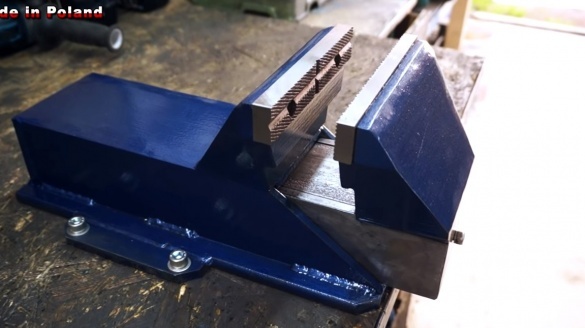

Step Five Making and installing vise lips

The lips of the vice must be strong, they have a lot of stress. For these purposes, the author used thick sheet steel. We weld lips to a vice, welds should be of the highest quality. The author’s lips turned hollow, however, they are quite strong and make the vice easier.

On the lips, it is necessary to install linings made of durable steel, it is better to buy such in advance. We drill holes for them and install using screws.

Step Six We are upgrading the hydraulic pump

Next, we have to upgrade the hydraulic pump, the point is that they can be controlled by the foot. First, the author installed a spring on the pump, which returns the pedal to its original position. The handle was also redone, now it is not a handle, but a pedal.

Similarly, we need to redo the valve to relieve pressure. The author welded a steel plate to it, and also installed a spring so that the crane spins itself.

Seventh step. Final touches and testing

As a finish, we paint all parts of the vice so that the metal does not rust. As for those nodes where friction is present, they need to be lubricated. That's all, now the vise is ready to use. The author demonstrates their work on video.

The weight of such a vice amounted to only 32 kg, that is, they can be transferred to yourself.

That's all, the project is over, I hope you liked the idea. Good luck and creative inspiration, if you decide to repeat it. Do not forget to share your homemade products and ideas with us.