Hello everyone, in this instruction we will understand how do it yourself You can make a small peanut peeling machine. With it, you can quickly and easily make nuts white and beautiful. This is true in cooking, where large amounts of nuts are required. The device operates on a 12V battery or any other power supply with a similar voltage and suitable current strength.

The heart of the typewriter is two small ones. All other structural elements are made with their own hands from available materials, mainly wood is used. Let's consider in more detail how to make such a machine!

Materials and tools used by the author:

Material List:

- ;

- 12V battery;

- a shovel from a shovel or the like (to make working shafts);

- two handles from electrical equipment (mounted on motor shafts);

- screws or screws;

- plywood;

- bearings and screws;

- a fan from the computer;

- wires;

- switch;

- A socket for connecting a power supply or battery.

Tool List:

- glue gun;

- drill;

- a hacksaw or other tool for cutting wood;

- screwdriver;

- soldering iron;

- hammer;

-line;

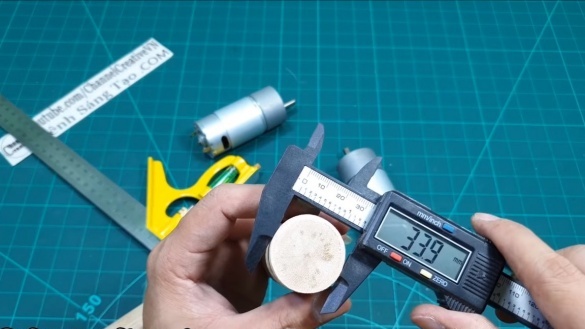

- vernier caliper.

Machine manufacturing process:

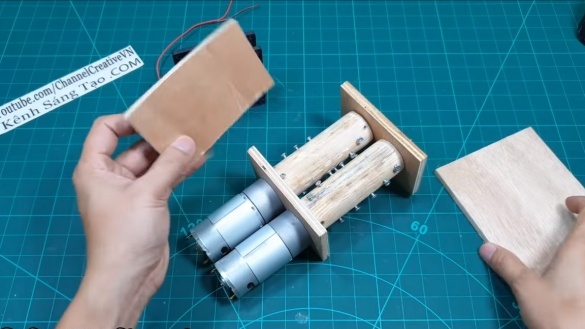

Step one. Production of working shafts

The working shafts are two shafts with "teeth" in the form of screws. The cogs are mounted in the form of spirals, when a nut falls between the shafts, the cloves rip off the husks from them.

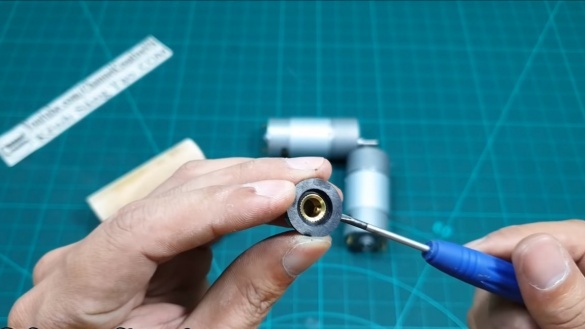

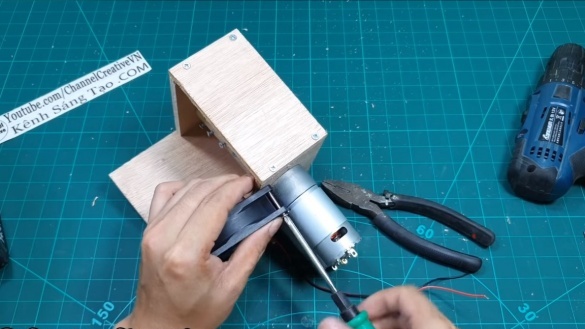

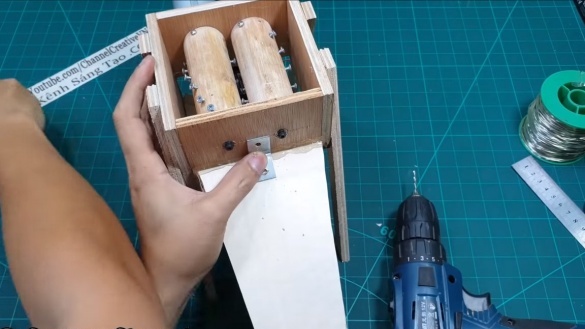

For the manufacture of shafts, we need a shovel handle or other similar stick. We cut off two pieces and install inside the insert so that the shafts can be fixed on the axes of the motors. For these purposes, the author broke two pens from electrical engineering, they contained inserts made of brass. For these parts, drill holes in the shafts and hammer them with a hammer. For reliability, we plant these parts on superglue.

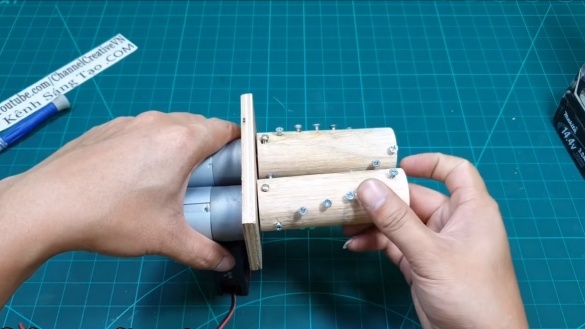

Now we need to install the cloves. For these purposes, we need a suitable screw length. We make markings on the shafts, drill holes and tighten the screws. Please note that both working shafts must not wedge during rotation.

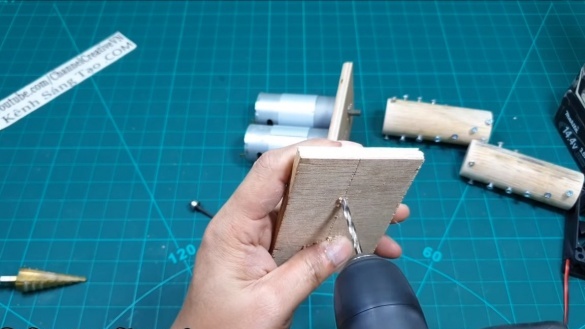

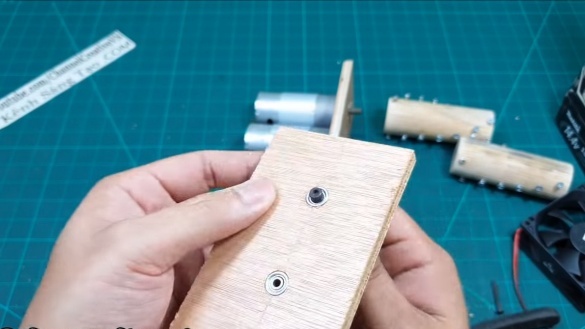

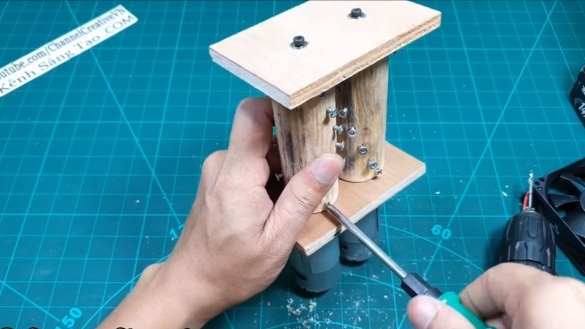

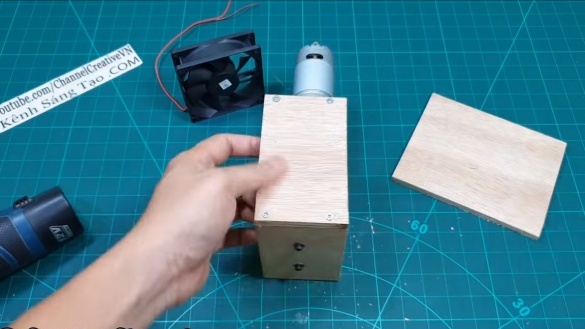

Step Two Frame manufacturing

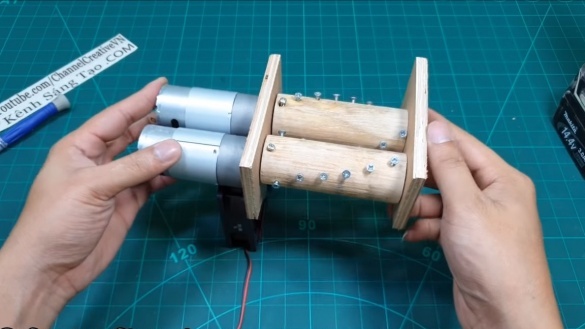

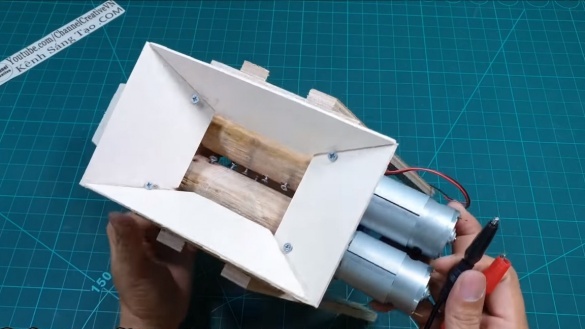

Next, we make the frame so that you can fix the engine and working shafts. For these purposes, we need plywood, cut it into the necessary pieces and assemble the frame using self-tapping screws. The shafts on one side will be located on the axes of the engines, and on the other hand we will install bearings in the frame and fasten the shafts on two bolts.When assembling this unit, note that thanks to the gearboxes, two motors can create considerable loads.

Step Three Fan

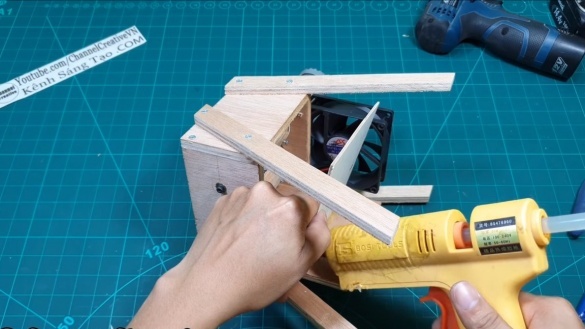

The design provides a fan from the computer. He is needed in order to collect husk from nuts. It is very light and our fan will cope with the task. We install it in the right place and fix it with screws.

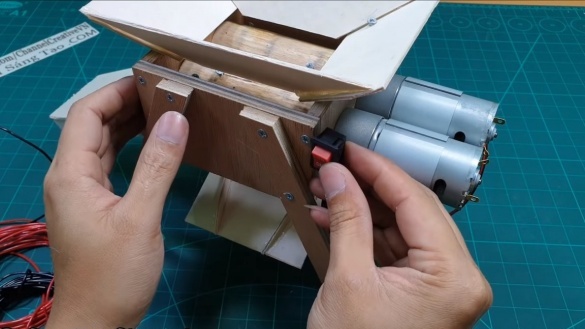

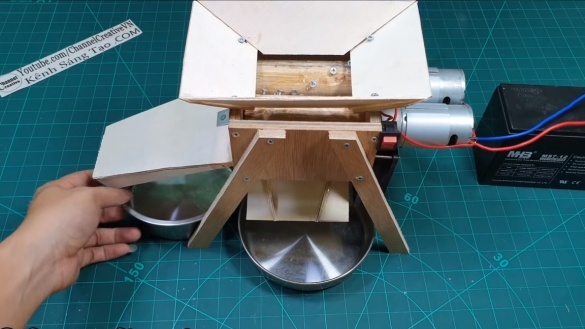

Step Four Feet and other construction details

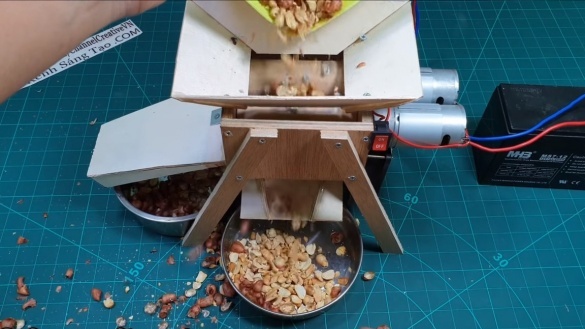

Make legs for the machine so that you can substitute a bowl under it, nuts will fall into it. The legs are cut out of plywood and fastened with screws.

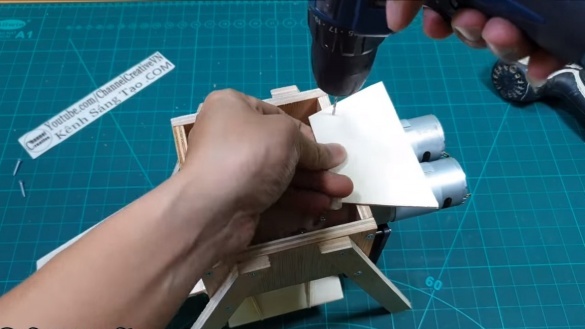

We will also need to make a bottom with guides, it is necessary so that the nuts do not fly from the machine anywhere. Of course, it will be necessary to make a neck so that it would be convenient to fill the nuts, and they would not fly out of the machine. We use suitable materials, we collect everything on hot glue and self-tapping screws.

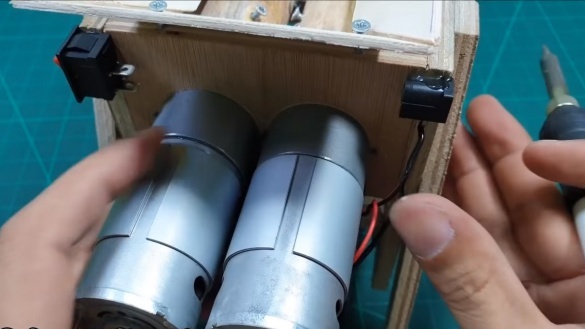

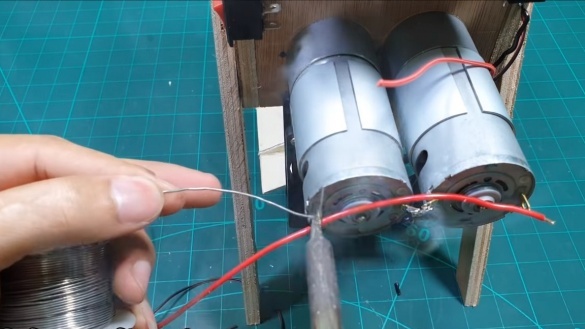

Step Five The final stage of assembly

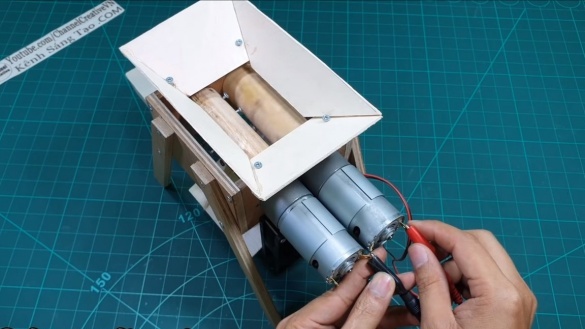

As a completion, we solder the wires to the motors, and also do not forget to connect the fan. The motor shafts must rotate towards each other, so experimentally we determine the necessary contacts. We install a switch, as well as a socket for conveniently connecting the power supply.

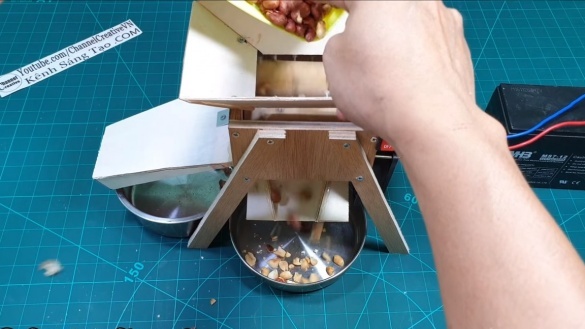

Step Six Testing car

We test the machine in practice, the author connects a 12V battery to it. We try to fill up nuts; after the first run, not all nuts are peeled. All we need to do is a few sweeps of nuts through the machine to make them clean. The husk will be sucked by the fan.

In general, the machine turned out to be quite good, however, it is necessary to modernize the working shafts in order to increase the efficiency. That's all, the project is over, I hope you liked it. Good luck and creative inspiration, if you decide to repeat it. Do not forget to share your homemade with us!