This article will be interesting to many of the residents of our sites, motorists and summer residents. Probably many of you had to use clamps in order to pull the hose to the pipe, or connect a couple of parts to each other. But not always a clamp of a suitable diameter is at hand. Sometimes it’s easier to use wire, but how to tighten it securely using primitive tools at hand?

In it, the author of the YouTube channel "George Kosilov" will tell you how to make a reliable clamp using simple materials.

The author previously made a clamp, but it is very difficult device. I will tell about him in another article.

Materials

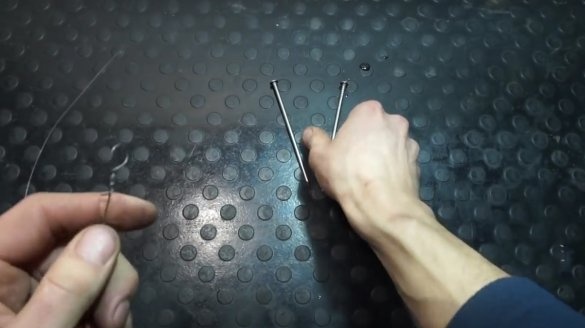

- A pair of nails

- steel wire

- Steel pipe and hose of suitable diameter

- Steel bar 6-8 mm.

Instruments, used by the author.

- Nippers

- Vise.

Manufacturing process.

At one end of the wire, the author makes a simple loop. Then he puts it on a nail, and clamps it in a vice.

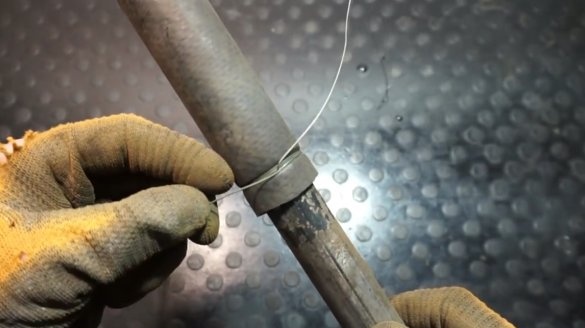

He puts the hose on the pipe, it can be seen that the hose easily slides along it.

It bites the edge of the hose onto the pipe, and begins to wind the wire around it. It is advisable to make three turns. Moreover, it needs to be wound round to round, and not to overlap.

Makes another loop at the other end of the wire, inserts a nail into it, and pulls the wire like a string. The tension force is about three kilograms. Then "rolls" a pipe with a hose along the wire.

In this case, the wire is squeezed into the hose right before our eyes.

Then he turns the pipe half a turn, making an overlap of the wire.

Bites off excess wire, leaving a couple of centimeters. And presses the edges of the wire with side cutters.

It turned out such a connection, you can see how much the hose has missed.

The author decided to check the reliability of the connection by holding the hose in a vice, and rotating it in different directions, first with his hands, and then with a key - a “crocodile”. The hose reinforcement is cracking, but the connection is holding.

Now the second way, with a similar principle. It is great if the pipe is fixed permanently. The author made something like a bow from a steel bar. Then he put on a hose, made three turns of wire, and then fixed its ends to the edges of the “bow”, like a bowstring. Of course, while creating tension.

Now a bow with a wire bowstring simply rotates around the joint. With each revolution, the turns are more and more tightened. At the end of the puff, the author again overlaps the wire.

The connection turned out, you can bite the excess wire. It is noticeable how much the bow was pulled.

This reliable and easy connection can be made in a couple of minutes.

Thanks to the author for sharing his idea!

All a good mood and quality connections!