The idea of the master is to install the stove outdoors and thereby save space in the workshop. The stove will heat the pipe laid inside it, and warm air will be blown into the room.

Tools and materials:

-Oven door;

-Barrel;

-Trumpet;

-Fan;

Corrugation

-Fasteners;

-High temperature paint;

-Welding machine;

-Drill;

-Drill;

Step one: door, chimney

Cut a hole in the barrel for the door and chimney. Drill mounting holes.

Step Two: Pipe

Inside the barrel, the pipe is laid with the letter U.

Step Three: Painting

Further, the master lights a fire in the barrel and warms the barrel. The oven temperature is 589 ° F or 309 ° C. Stains the stove.

Step Four: Corrugation

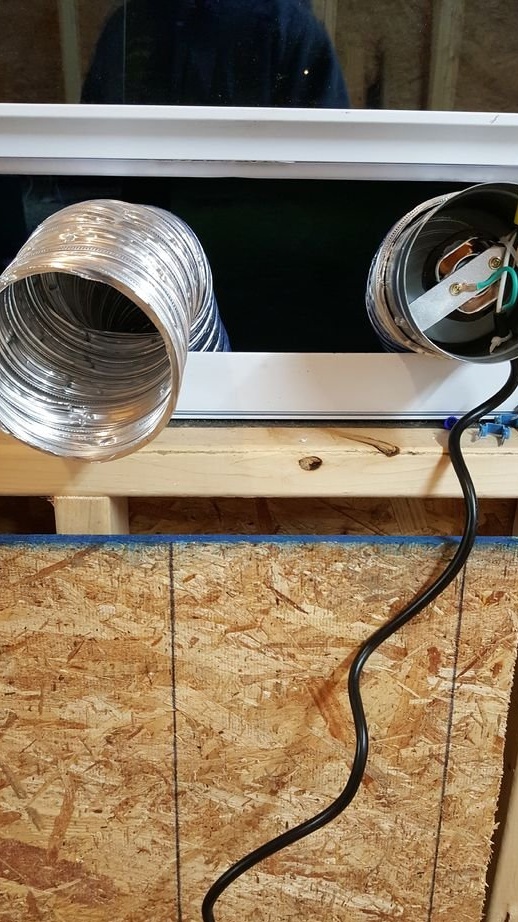

From the pipes of the heat exchanger to the workshop, the master paves the corrugation. Through one corrugation, the air will be sucked in and enter the heat exchanger, another outlet. The master installs a fan on the inlet pipe.

Step Five: Testing

Testing showed that the outlet temperature gradually rose to 143 ° F (61 ° C). And the temperature on the street was 30 ° F (-1 ° C).

All is ready.

The idea is not bad. Of course, the service life of such a furnace raises the question, after all, the metal on the barrel is thin. Well, it would not hurt to make good thermal insulation.