In this article, the author of YouTube channel "Be Creative" will tell you how he made a powerful desktop clip.

The design turned out to be very interesting, and you can clamp the part in it much faster than in a vice.

Materials

- Steel profile pipe 25X25 mm

- steel strip

- Eccentric

- Part of the housing from the bearing

- Door hinge

- A pair of bushings

- steel bar

- spring

- Solid oil or lithol

- Bolts, nuts.

Instruments, used by the author.

- Welding machine

- Bulgarian

- Screwdriver

- Drilling machine

- Vise

- Marker.

Manufacturing process.

To begin with, the author marks two sections of the profile pipe, clamps it on the table of the drilling machine, and drills two holes in them.

Prepares parts for sponges from two scraps, trimming one short side with a grinder.

These are two such blanks.

Now clamps them, and drills holes for the fixing bolt.

Marks the door hinge and cuts off part of it with a grinder.

Tries on pipes to a loop and welds.

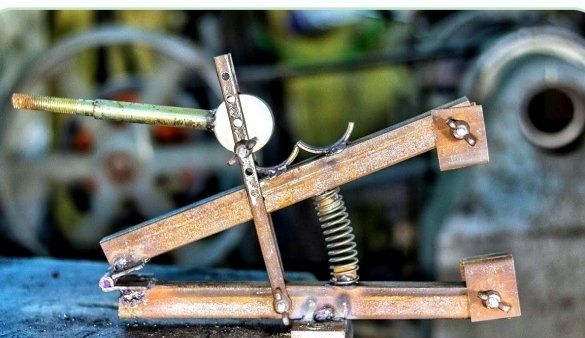

It turns out this is the main part of the device.

On a steel strip marks the places for drilling, and makes holes. These will be guides with which you can adjust the distance between the jaws.

A steel bar welds to the eccentric, it will be a clamping handle.

It installs sponges, and fixes with bolts with wing nuts.

Further, the author welds two bushings to the middle of the profile pipes, they will hold the spring.

Now installs the spring on the bushings.

A half from the bearing housing is welded to the upper pipe, an eccentric will be in it.

Assembles the structure further, connects the eccentric to the guides.

Screwing device To the table, the author has welded another half of the bearing housing, so it will be possible to set a different degree of pressure.

Lubricated the halves of the bearing with grease.

In the distant position, the eccentric sponges do not converge completely, it is convenient for clamping large parts.

In the near position, the fit of the jaws is complete.

This is how you can fix the steel strip.

In the distant position, it is possible to fix a pair of profile pipes.

Thanks to the author for the interesting idea of such a quick-clamping system!

Good mood and good luck to everyone!