Hello everyone, in this instruction we will discuss how to make a simple and unusual pump based on. The peculiarity of the pump lies in the principle of its operation, there are no impellers or cylinders with pistons, the principle of operation is similar to the principle of the heart, of course, all this is very distant. The design of the pump is a soft silicone hose, on which the wheels ride and squeeze it. As a result of this, the hose is divided into chambers, which are displaced together with water and pump it. Everything is made of available materials, the pump is quite productive, although it is not known how long the hose will last, but even if it is wiped, it can be easily and quickly replaced. If you are interested in the project, I propose to study it in more detail.

Materials and tools used by the author:

Material List:

- automotive silicone hose or the like;

- boards;

- screws;

- 3 screws with nuts;

- ;

- a bolt with a nut for an axis;

- suitable sealing material.

Tool List:

- drill;

- drawing instruments;

- a hacksaw;

- sandpaper;

- jigsaw.

Pump manufacturing process:

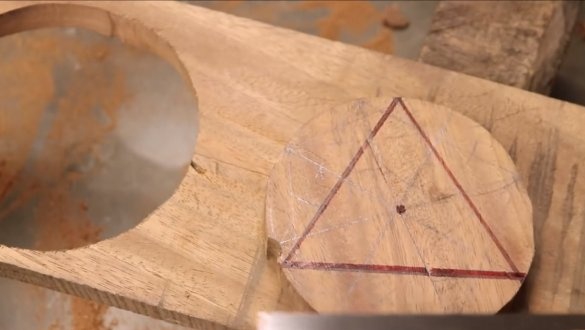

Step one. Body manufacture

We begin to manufacture the pump from the body, here we need boards and a crown for a drill. Cut a round in the board and do not throw it away. This round timber needs to be marked out and an equilateral triangle cut out of it, this will be the working body of the pump in the future.

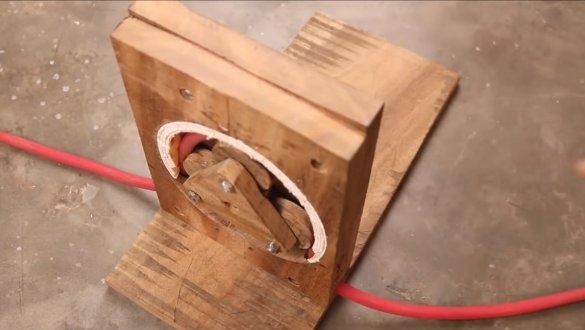

After cutting, you should get another clip, carefully process it with sandpaper, and then screw another board to the clip, this will be the back wall of the device.

Step Two Hose

Inside the clip you need to lay the hose, drill holes for it. The holes must be drilled at an angle so that the hose does not scroll during the process, and we also select the diameter so that the hose fits tightly in the holes.

Step Three Work unit

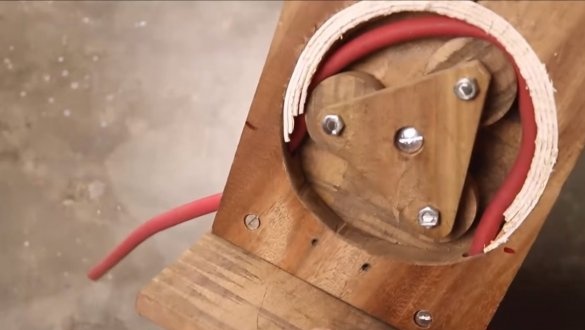

This pump element is an equilateral triangle, at the ends of which rotating wheels are fixed. We cut the wheels with a drill using a crown and grind well so that they are smooth and do not damage the hose.

The wheels should rotate easily, the author fastens them with screws, which have no thread near the hats, as a result, the wheels rotate on the axes very light. The excess parts of the screws are cut off with a grinder.

As the axis for this entire assembly we use a bolt with a nut. The axis rotates simply in a wooden board, but it would be better to install a bearing here to increase service life and increase efficiency.

Step Four Assembly and testing

We put a hose inside the pump. The wheels must pinch it, so that a seal of suitable thickness is laid along the clip.

We attach the pump to the base, which is the board, after which the axis of the device can be clamped in the cartridge.

We turn on the pump and try to pump water. The author on the video shows how everything works. The pressure turns out to be quite good, the water flows pulsed, the performance depends on the speed that a screwdriver can produce.

That's all, the project is over, I hope you liked it. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas with us and homemade!