Good day to all. In this article, I’ll tell you how the author of the channel “Mr SunY” assembled such a puller do it yourself.

Materials:

Steel square

Bolts

Nuts

Washers

Hairpin M12

The nut is ordinary. M12

The nut is extended. M12.

And a steel strip.

Instruments:

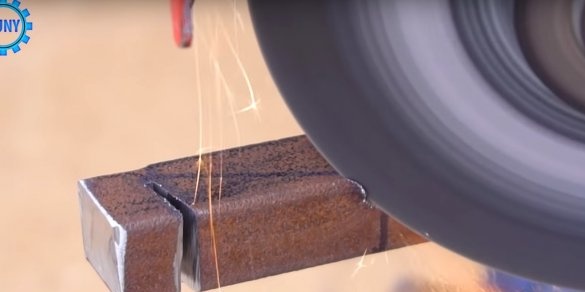

Angle grinder

Cutting wheel

Petal circle

Drill

Welding machine

Electrodes

Spanners.

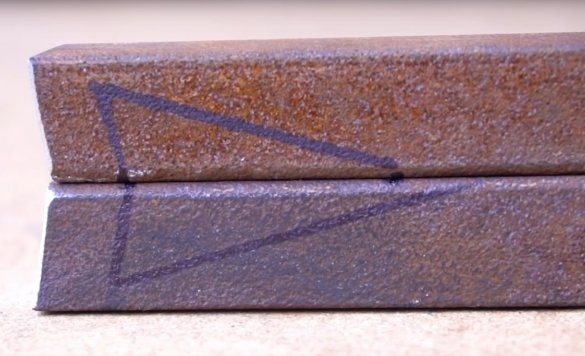

The author cut off two pieces from the square.

Then he made the markup, as in the photo.

After deleted unnecessary.

Then he measured and cut off two blanks from the strip.

After folding the blanks as shown in the photo.

On the strip marked the place under the mount.

Then he made holes.

After noted and made holes in the square.

Next collects the details.

By laying the elongated nut on the strip between the squares.

And setting the second piece of strip on top.

Fixes all parts with nuts, not forgetting to put washers on them.

Something like this.

After installed the hairpin.

Cut off excess from bolts.

He welded the nut to the strip, holding it with a stud.

Then removing the hairpin, he sewed one of its edges under the cone.

And on the second edge, I installed a regular nut.

Then he welded it to the hairpin.

Next, set the pin in place. That's all, the puller is ready.

And now the test.

This puller copes with its task no worse than a store.

And that’s all for me. Thank you all and see you soon!