For this article, which took part in the competition of articles on the manufacture of aircraft models, the author was awarded by me with a cup. I think that the author will not be offended by me if I call his name - this is a young model aircraft designer Pavel Ruzhnikov.

The cup was made by me specifically for this award.

TTX.

Span - 1200 mm

Length - 1120 mm.

Motor - any with a thrust of 800 g.

Screw - 10 x 6.

The regulator is 4-A.

Servos - NHT900.

The battery is 1500 3S.

The total weight of the model is 600 g.

Drawing and material for building the model.

As usual, the author decided on the scale of the model, made drawings and cut out patterns from them.

Model built in their free time.

The author began to create a model from the wing.

The author did not repeat the proposed version of the model and made changes to its design.

As the first of his innovations, the author put two spars in the wing.

One, the main spar is assembled from three layers of the ceiling. The author made the trailing edge of the wing from a ceiling 5 mm wide.

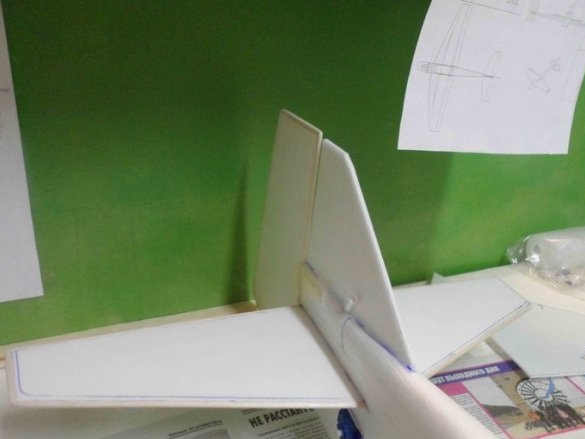

Work began on the creation of the tail of the model. The main elements of the tail are made in one layer of the ceiling. With subsequent strengthening of the edges with balsa.

The author notes that this part of the model is very fragile and requires special care in handling transportation and even when storing the model.

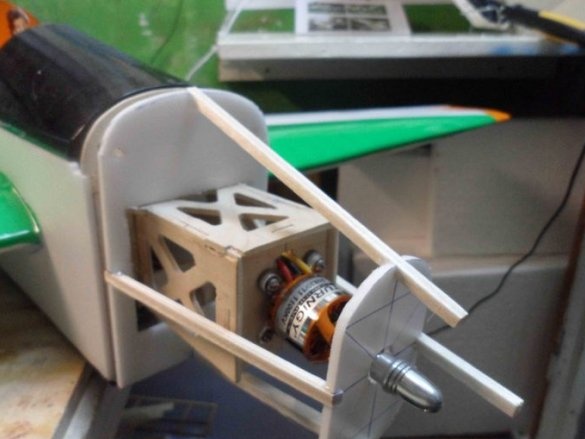

Parts for mounting the motor, lateral fuselage planes, frames, stringers are made. All parts are glued into the grooves prepared for them. that everything glues groove into groove. The author made the details of the motor mount from plywood from boxes for oranges.

For the manufacture of stringers, the author used wooden slats with a cross section of 4 X 8 mm.

Before installing the servos, special places are prepared for their installation. This must be done until the fuselage tail casing is installed.

The central supporting spar is made of wooden battens - 10 X 5 mm. For this purpose, you can use other materials, carbon fiber rod or tube. It all depends on your capabilities.

The author draws attention to the fact that the wing is made whole. So - as the size of the model is small,

and for the installation of a collapsible wing requires special fasteners.

This simplifies the design.

In the central part of the wing, where the wing is glued to the fuselage, additional plates are glued to evenly distribute the load. The frame in this place is made in two layers of the ceiling.

When installing the wing on the fuselage, it is very important to be horizontal, to prevent the wing from being installed at an angle.

When installing the tail unit, it is necessary to observe right angles and alignment with the model as much as possible.

The keel is glued.

Work begins with the cockpit.

Ceiling is carried out.

He planted a funny pilot figure.

Installation of the motor ends.

The engine is mowed 2 degrees down, 1 degree to the right.

Further, the author proceeded to cover the model with colored tape. The author does not insist on repeating the color palette. This is a matter of taste for everyone who decides to repeat the model.

All control surfaces, namely: elevator, rudder and ailerons are hung on ordinary tape.

The coloring of the model proposed by the author looks good in the sky and is very different.

The hood for the engine was created using composing technology, covered with a film for aircraft models.

The CT model is located in the calculated location - 28% of the wing chord.

Video of the first flight.

Bye! Until we meet again, In ..