The company of the master who built this paint booth is engaged in building houses, as we say turnkey. The master makes various wooden elements in the construction of houses in his carpentry workshop. To paint them, the master decided to build a spray booth.

Tools and materials:

-Metal framework;

-Boards;

-Plywood;

- MDF with melamine coating;

-Fasteners;

-A screwdriver;

-Circular machine;

-Wheels;

-Hammer;

- Clamps;

-Paint;

-Fan;

-Electric motor;

-Luminescent lamps;

-Activated carbon;

-Glass cloth;

-Nylon mesh;

Step One: Project Development

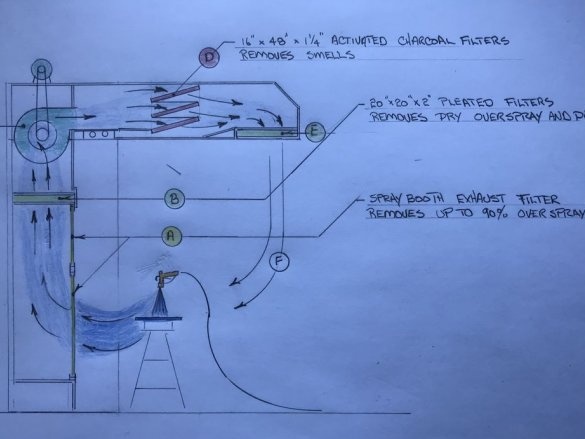

The master immediately says that such a design was developed specifically for water-soluble paints. As can be seen from the figure, four filters are installed in the chamber. Filter A B and E, these are ordinary filters for hoods. Filter D, a carbon filter made by a craftsman.

Now consider the operation of the camera. When painting a part, air with paint particles is drawn in by the flow of air into the air channel. In this case, up to 90% of the particles are deposited on the filter A. Then the air enters the filter B and the carbon filter D. In principle, the air has already been cleaned of paint impurities, but the master also put one filter at the outlet of the channel. After passing through the filter E, the air again enters the spray booth.

Step Two: Wireframe

Frame master made of old metal frames. I connected the frames with the letter P and sheathed plywood. For ease of movement installed wheels.

Step Three: Air Channel

Then secures the inner frames. Installs a fan on top. The fan, through the drive belt, is powered by an electric motor.

From above fixes a frame for a peak. Covers the top of the camera with plywood.

It covers the visor on top with plywood, and sets filters on the bottom.

Installs filter A.

Step Four: Sash

On the sides of the chamber, sashes made of melamine coated MDF are installed. Installs fluorescent lamps.

Step Five: Carbon Filter

The carbon filter is a fiberglass stretched over a wooden frame. A nylon mesh is laid on top of the fiberglass.On top of the grid, the master evenly poured activated carbon.

Now you need to transfer the stand to the spray booth.

All is ready. In the bottom photo you can see the result of coating the product in the spray booth.