The master made such a press as a demonstration model to school. Despite the apparent fragility, such a press easily crushes a glass bulb or aluminum can.

So, for the manufacture of a hydraulic press, the master used the following

Tools and materials:

- Syringe 100 ml - 4 pcs;

- 5 ml syringe - 1 pc;

- Check valve - 2 pcs;

-Plywood;

-Glass capacity;

-Drill;

-Glue gun;

- Electric jigsaw;

Epoxy resin;

- dowels;

-Plastic tube.

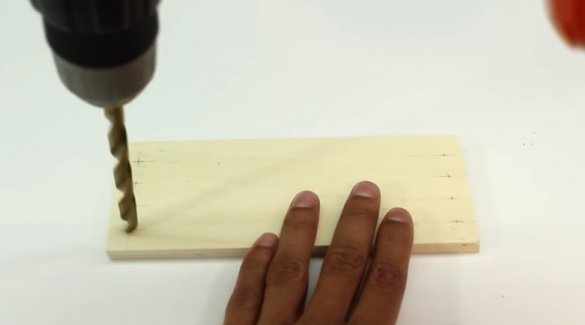

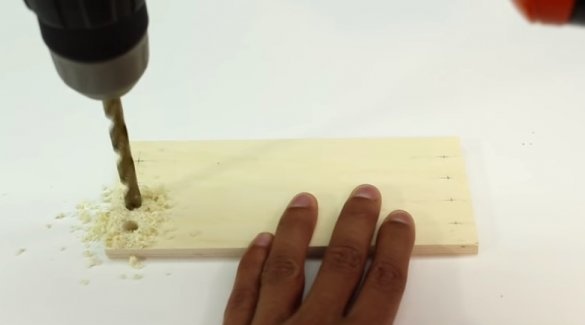

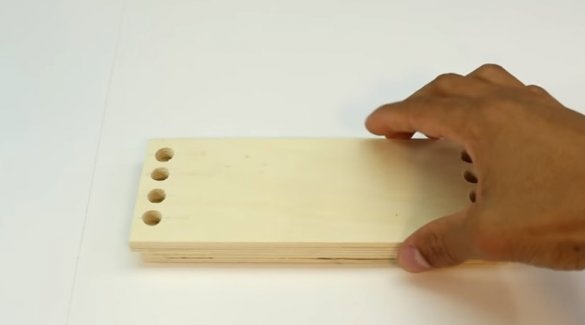

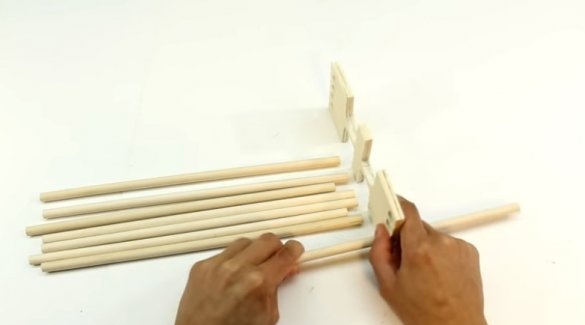

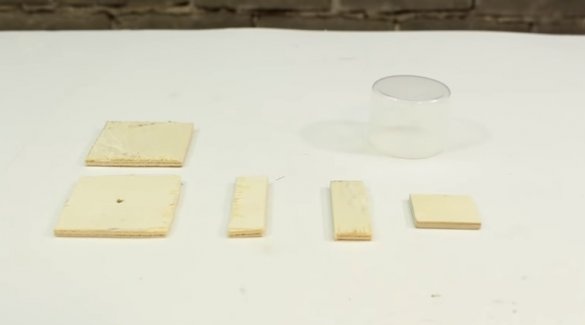

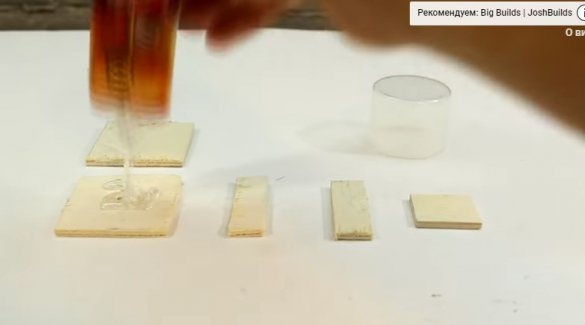

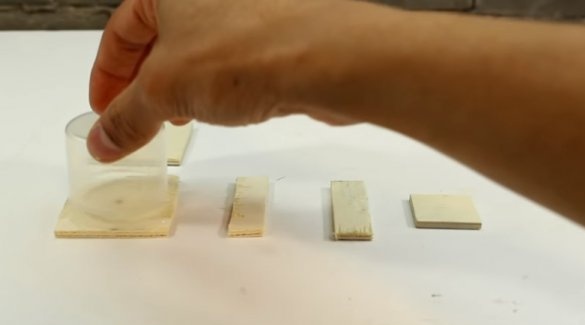

Step One: Billet

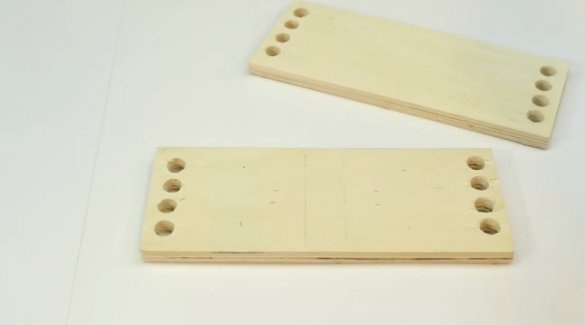

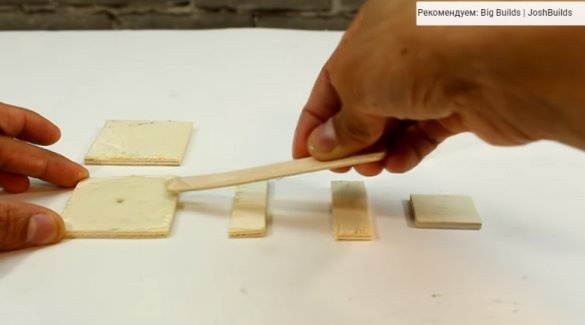

From plywood, you need to cut five rectangular blanks. Four pieces must be glued together in two pieces. Drill four holes along the edge of the workpieces along the dowel diameter. Cut openings for syringes in one double blank.

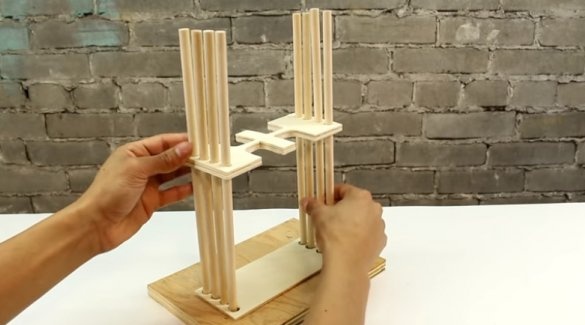

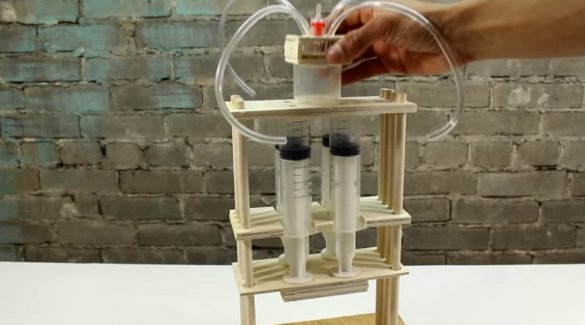

Step Two: Assembly

Pulls dowels into the holes of the workpiece.

In a thick sheet of plywood (base) drills holes coaxial with the workpieces.

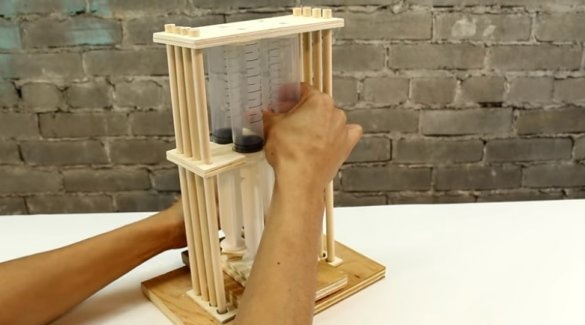

Collects the press, as in the photo.

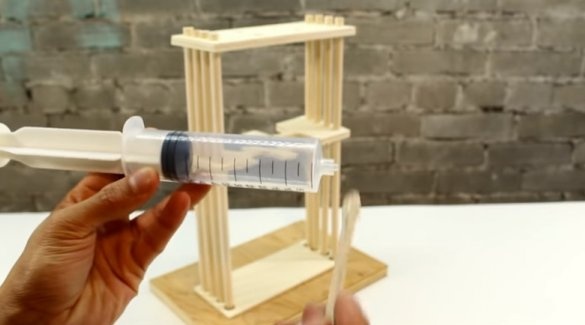

Step Three: Syringes

In the top cover, drills holes for syringe spouts. Apply epoxy glue to the top of the syringe cylinders. Glues syringes to the top cover (it is important to leave a space between the nozzle of the syringe and the wall of the hole).

Step Four: Press Plate

Glues the blank to the rod stops.

And a double plate.

Step Five: The Base

He wears glue in the holes of the base and installs dowels in them.

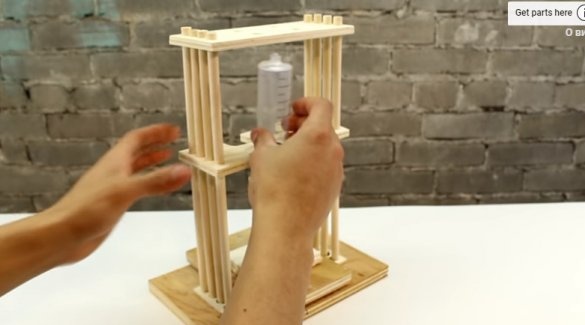

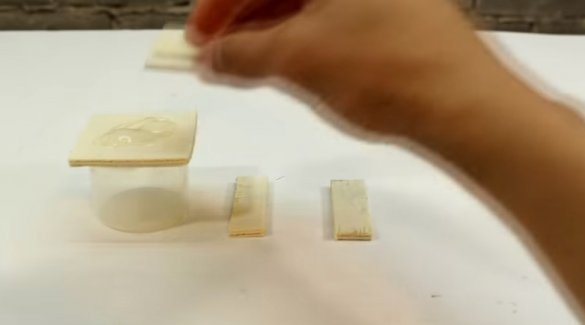

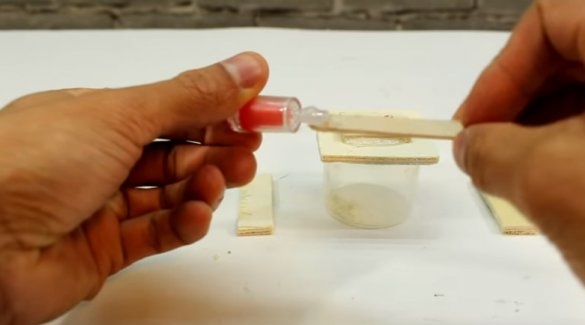

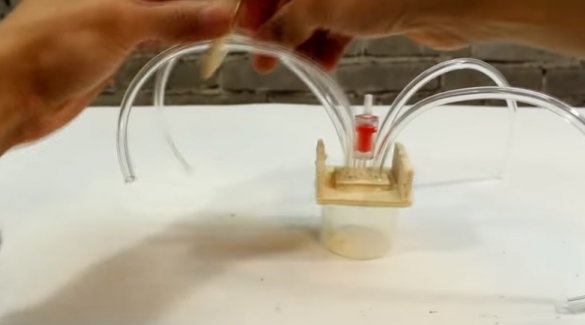

Step Six: Pumping Tank

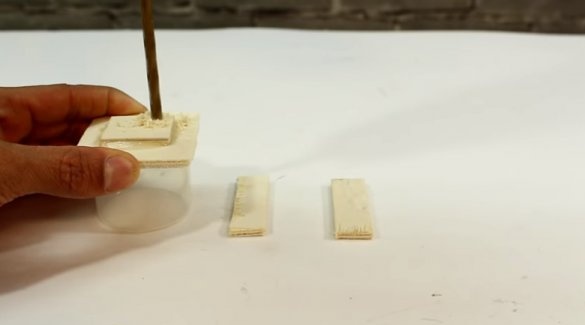

A square of plywood is glued to the glass jar, and on top is another smaller one. Drills five holes in the workpiece.

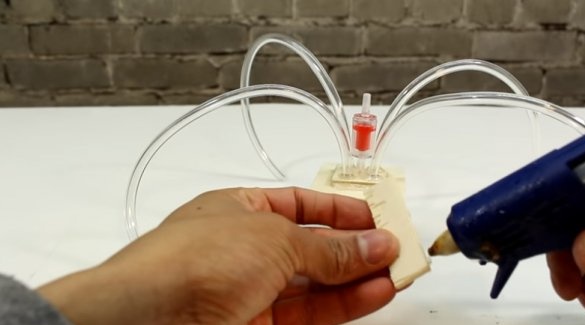

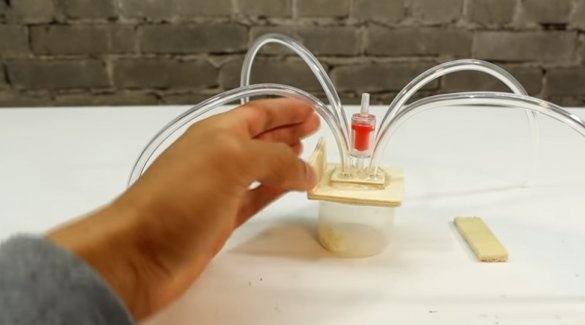

A check valve is glued into the hole in the center, tubes are glued into the holes along the perimeter. Glues the sidewalls. He puts a cap with holes on the tube. Glues it to the sidewalls.

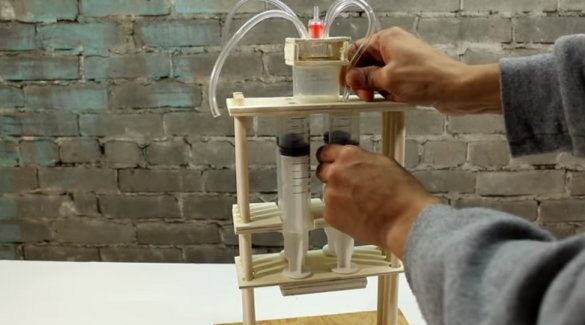

Glues the tank to the top cover, glues the tubes to the nozzles of the syringes.

To avoid leaks, the master glued all the joints with epoxy glue + applied glue on top of the joints.

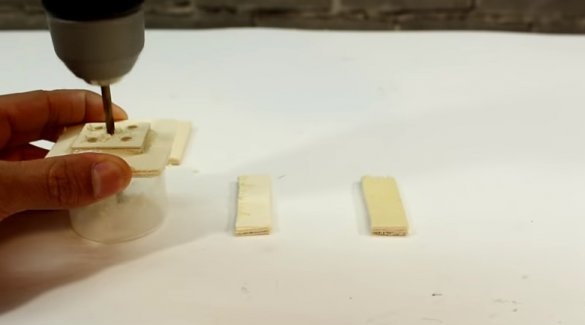

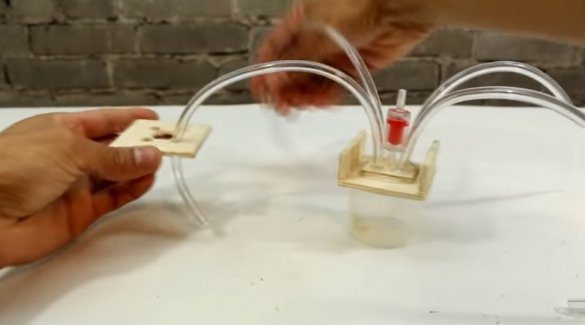

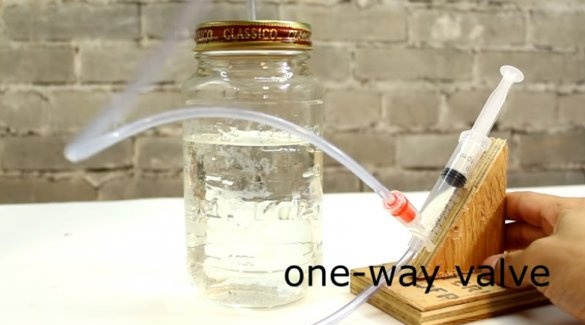

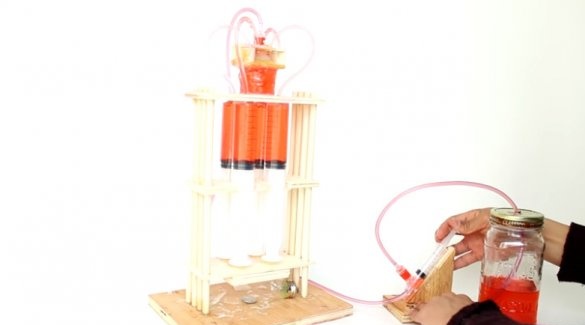

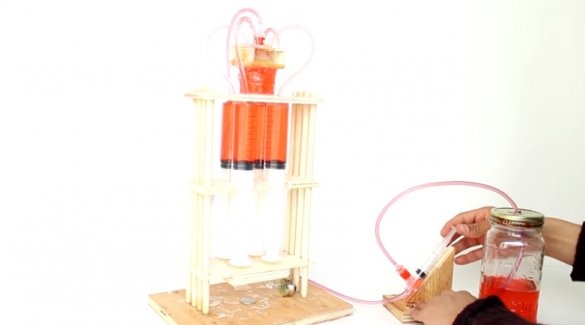

Step Seven: Discharge Pump

The master made the injection pump from a 10-cc syringe. But first you need to make a foundation for it from plywood.

A syringe is fixed on the base.

A hole is drilled at the bottom of the cylinder. Glues a check valve into the hole. A tube is put on the valve, the second end of which lowers a container with liquid. On the nozzle of the syringe puts on a tube going to the valve of the pumping tank. Pulling the syringe rod toward itself, fluid from the container will be pumped into the syringe. Then the rod is recessed and the fluid is pumped into the pumping tank, and then into the syringes.

Everything is ready and the master gives several examples of the work of the press.

Crushes a toy.

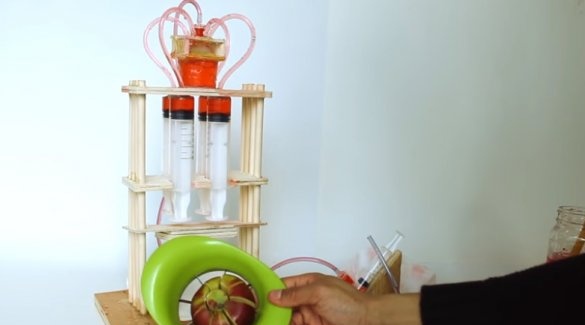

With the help of a press and a cup with knives, he cuts an apple.

Squashes the light bulb

and flatten the aluminum can.