Where to get the old parts from the car? You can hand them over for scrap, or you can, as a student from Pakistan did, make them a useful, exclusive item. In this case, we will analyze the manufacture of a bar stool. The photo shows that the master did a great job turning the piece of scrap metal into an original chair.

So, for the manufacture of such a chair you will need the following

Tools and materials:

-Front strut assembly with brake disc, caliper and hub;

- metalwork tool;

-Metal brush;

- Sandblasting equipment.

-Aerosol paint;

-Drill;

-Welding machine;

-Board;

-Sheet metal;

-Capacity;

-Petrol;

-Retail;

- Joiner's glue;

- Electric jigsaw;

-Grinder;

-Varnish;

-Fasteners;

Step one: disassembling the assembly

The step is quite simple, you need to completely disassemble the node. Remove the spring, hub, bearings, caliper, etc. Removing the springs must be done with caution using a puller.

Step Two: Cleaning

Now you need to clean all the nodes and parts. Before the next operation, it is necessary to remove dirt and oil leaks from the parts with a wire brush.

Now you need to rinse the parts in gasoline and dry.

Step Three: Sandblasting

Of course, it is impossible to manually clean an old part of such a complex shape to a shine. Sandblasting helps to achieve this.

Step Four: Spring Trimming

In order to loosen the spring, the master cuts one of its turns. In this case, the spring will not put pressure on the plate.

Step Five: Painting

The parts are thoroughly cleaned and you can begin to stain them. For contrast, the master paints different details in different colors.

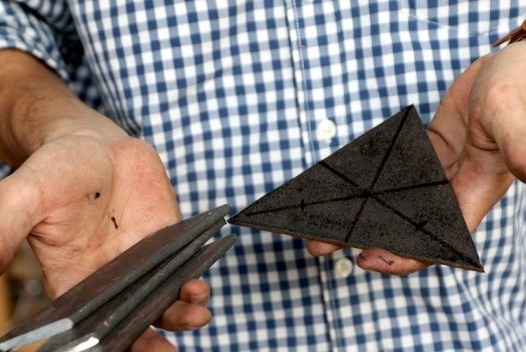

Step Six: The Base

To install the rack in an upright position, the master makes a stand from 5 mm sheet metal. Cut a triangle and three parallelograms. Drills two holes in a triangular part.

Then it is welded to the triangular part of the parallelogram.

Colors the part.

Seventh step: assembly

Screws the stand to the stand.

Installs brake disc with caliper.

Screws on the hub.

It puts a spring.

Step Eight: Thrust Bearing

To fix the seat in the metal plate of the thrust bearing, drills holes and cuts threads.

Step Nine: Seat

The master made a seat from three boards. At first he glued them together.

After gluing, cut out in the shape of a circle and polished.

Coated the surface with varnish in several layers.

Then you need to drill mounting holes and secure the seat.

Here such a bar stool turned out from the master from old unnecessary details.

The whole process of making such a chair can be seen in the video.