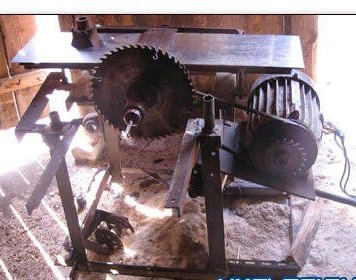

Without a conventional woodworking machine in its own suburban area in any way. It is especially indispensable when you constantly need to tinker at the cottage and equip your own courtyard with your own.

Such a machine is extremely compact, simple, multi-functional - it cuts, mills, planes, sharpens and hammer.

Step 1. The basis of the whole product is a welded frame, the creation of which is not particularly difficult. You can weld it from an ordinary steel corner with dimensions of 40x40 mm, but the height of the product must be calculated so that the machine itself turns out to be about the waist, since this is the most optimal size of the machine.

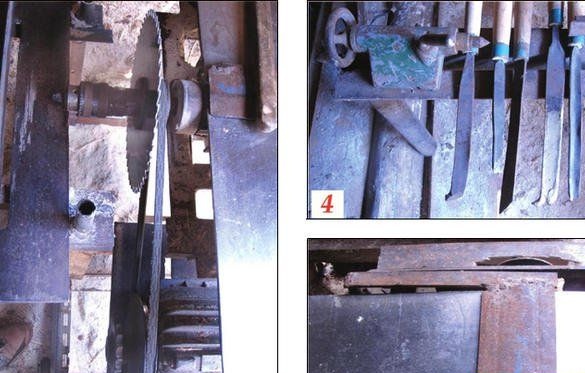

Step 2 A shaft with a small two-knife planer, the width of which is 200 mm, is attached to a special frame on special bearings. But the planer table should be exactly the same width made of stainless steel with a thickness of 5 mm.

Step 3 A milling cutter is installed on one side of the shaft with a special standard side table, which will be designed to cut various parts.

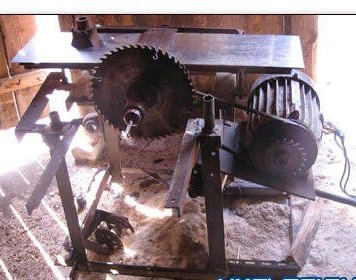

Step 4 After this is the installation of the cartridge. In this cartridge, you must insert the trident of the lathe itself. But a special prefix is attached to the frame with the device necessary for fixing the workpiece itself, as well as with a metal stop directly for work.