Hello, friends the inhabitants of our site and site visitors!

I collected another homemade product that I bring to your attention. This device reduces the inrush current through the lighting lamp by 220V at the time of its inclusion, thereby extending its service life.

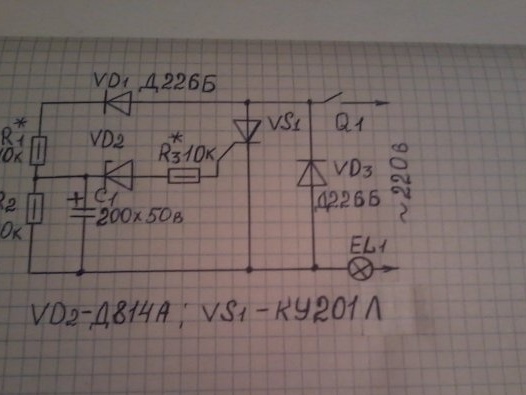

Many of you know how often you have to change burned out lighting lamps at home or in your apartment. This home-made lamp turns on for 2 seconds after turning on the chandelier switch. Here is a homemade scheme

I took it from the magazine Radio No. 7 of 1988. This machine works like this. When the contacts of the Q1 switch are closed, the EL1 lamp starts to glow completely, since the current flows through it only during positive half-periods of the mains voltage on the lower, according to the scheme, power supply wire.

During negative half-cycles, capacitor C1 is charged. As soon as the voltage across the capacitor reaches the stabilization voltage of the Zener diode VD2, the thyristor VS1 opens and the lamp flashes almost to full heat. The parts shown in the diagram are designed for operation of the machine with a lamp (or lamps with power up to 150W). For a more powerful load (500-700 W), you need to install a VD3 diode with a permissible rectified current of 2 -3A, (for example, KD202L). In this case, the thyristor can not be installed on the radiator. To assemble this device, we need the following parts and tools.

1 - a small circuit board; Thyristor KU 201L; two diodes D226B; Zener diode D814A; resistors MLT-0.5 W 120 com; and two for 10 com; 200 uF capacitor at 50 V; elektrolampa 95 W 220V for setting up the machine.

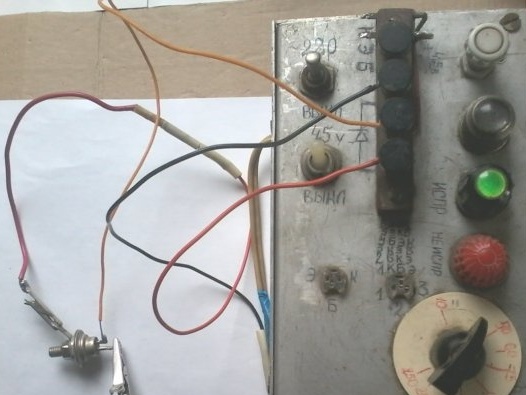

2 - mounting wires; soldering iron; solder; tweezers; Variable resistor Sp -1 22kom for tuning; nippers; pliers; multimeter; drill, drill. We assemble the device as follows.

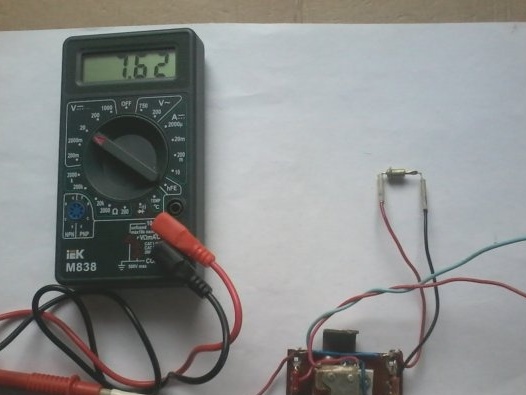

Step 1. We check all the radio components for their serviceability.

Moreover, I checked the thyristor and the zener diode with my previously made home-made products.

Step 2. Install the thyristor, diodes and capacitor on the circuit board.

Step 3. We solder the entire circuit of the device, check the correct assembly. The whole process of verification and assembly is shown in the photo.

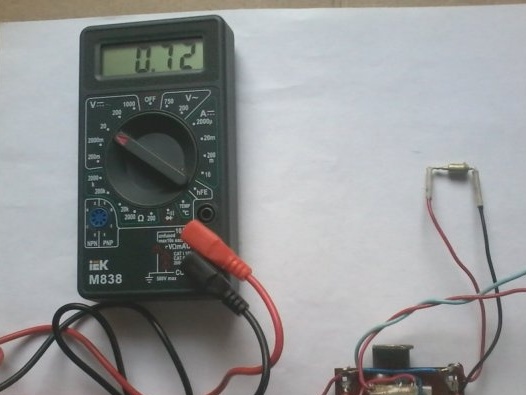

Step 4We are setting up the device. To do this, turn off the VD3 diode. Instead of resistor R3, we temporarily solder a variable resistor with a resistance of 22 kΩ. A few seconds after turning on the device, the EL1 lamp should light up with a blinking light. If the lamp does not light, we select the current of the thyristor control electrode with a variable resistor. Then we measure the voltage across the capacitor C1. If it exceeds 50 V, Replace the capacitor with another one with a large rated voltage. After that, we connect the VD3 diode and measure the alternating voltage on the lamp. You can change it in one direction or another by selecting the resistor R1, but it is undesirable to significantly reduce the resistance of the resistor compared to that indicated on the circuit, otherwise the duration of the preliminary heating of the lamp filament will decrease (it should not be less than 2 seconds) - until the thyristor is turned on.

Here is a simple homemade product that extends the life of lighting lamps. The assembled device must be placed in a suitable plastic case and placed in a chandelier, connecting the lamps according to the diagram. I wish you all great success in your work.