I am sure that each of you, dear readers and masters are friends, there is a screwdriver in the household.

I also have. Simple, reliable, with two batteries and charging.

With a charge indicator and LED illumination of the working area. Here it is.

I did not buy it, they gave it to me. It is written that it is German, but inside, as usual, everything is Chinese. Nevertheless, for many years he has been serving faithfully, even from him you can see where he just did not work ...

But recently, the batteries began to charge for a long time, quickly run down, power dropped. It is clear that it is time to change them. Of course, I will change them, as soon as I get rich, into modern lithium ones. Of course, myself, do it yourself I’ll change, especially since the site has told about this many times.

But the trouble is, right now I just really need a screwdriver. Urgent work is worth it. And I decided to temporarily power it from ... a car battery. Fortunately, there are already four car batteries in my household. And what, the shurik's native battery is 14.4V, and a freshly charged car shows 13V. It should work.

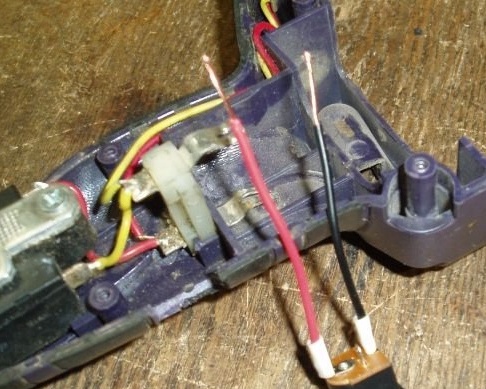

We disassemble the screwdriver and for the test we connect the wires from the laboratory power supply. We check. At a voltage of 12V, the starting current is 5A, under a load of 3A. It spins quite fast.

We select the power connector remaining after repairing the laptop for one friend. (I bought two then, just in case).

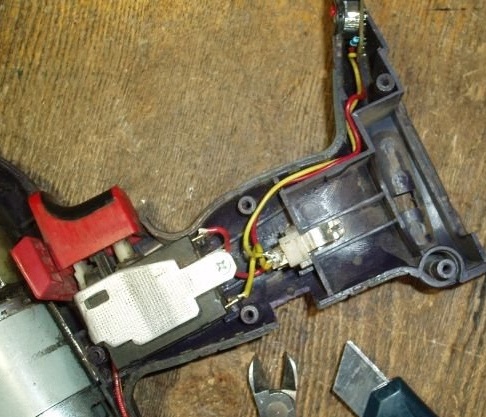

I thought for a long time where to adapt it so that there was enough space, and that the wire did not interfere with work. And I found - yet I was this place. Right in the handle. And the hand does not hurt, and the wire does not dangle.

Using nippers and a sharp knife, cut out the groove for the connector. We insert the nest, collect the shurik, check how it will look. So, it seems nothing. I like.

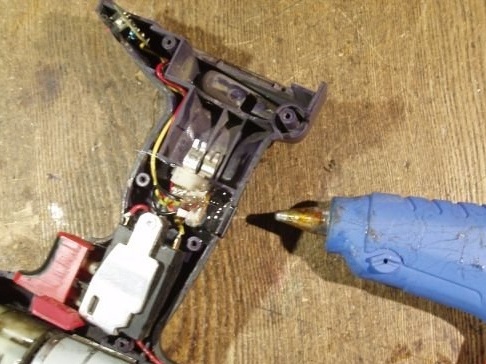

We solder a piece of thick, powerful wire from the old extension cord (about 2.5 m) to the plug, connect the socket of the connector to the knife contacts of the battery and from the power supply we check once again how everything works, whether the connector or wire is heated during operation.

After that, fill with the hot glue the installed power connector in the body of the screwdriver. After the assembly, it turned out like this.

In the photo, the kit is ready for battle.

The next check is already from the car battery. At the first speed, the indicator on the shurik indicates that the battery is half discharged.

At the second speed, the indicator shows a discharge of 30%. It’s clear, because through the gearbox the load on the screwdriver motor is much less.

Along the way, I note that the native battery is also inserted in it, it works like a buffer, mitigating the inrush of current at startup, and at the same time is recharging. Of course, with a cord a little less freedom of movement, but with a car battery you can turn the screws for at least a whole day. And on the way home from work, the car battery also recharges. Well, and when we finish the work, I’ll get rich right away and buy lithium batteries. But I’ll leave the connector with the cord anyway.